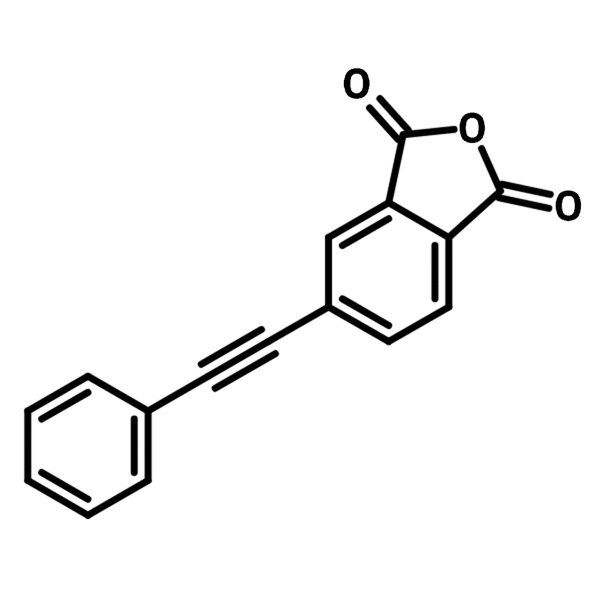

4-Phenylethynylphthalic anhydride (PEPA)

CAS Number 119389-05-8

Chemistry Building Blocks, Heterocyclic Building Blocks, Materials, MonomersA phthalic anhydride intermediate

For the synthesis of polyimides as end-capping reagent in application of gas separation membranes and high-performance polymers

Specifications | MSDS | Literature and Reviews

4-Phenylethynylphthalic anhydride (PEPA), CAS number 119389-05-8, a phthalic anhydride derivative, has a phenylethynyl substituent at 4-position. 4-Phenylethynylphthalic anhydride is commonly used as an end-capping reagent for polyimides synthesis and modification, such as TriA-X polyimides. The diphenylacetylene end-capping moiety undergoes thermally induced radical curing process for crosslinked polyimides. The crosslink further improves the thermal stability of the polyimides (5% decomposition temperature Td5 = 591.3 °C). Diphenylacetylene also reacts with tetraphenylcyclopentadienone forming a fully conjugated hexaphenylbenzene under Diels-Alder reaction.

PEPA can also be introduced as an imide pedant onto a polymer backbone that has free amines. The modified polymer membranes show improved gas permeability in application of gas separation.

General Information

| CAS Number | 119389-05-8 |

| Chemical Formula | C16H8O3 |

| Full Name | 4-Phenylethynylphthalic anhydride |

| Molecular Weight | 248.23 g/mol |

| Synonyms | 5-(Phenylethynyl)isobenzofuran-1,3-dione, 5-(Phenylethynyl)-2-benzofuran-1,3-dione |

| Classification / Family | Anhydride building block, Separation membranes, High-performance polymers |

Chemical Structure

Product Details

| Purity | >99% |

| Melting Point | Tm = 152 °C |

| Appearance | Pale yellow to yellow powder/crystal |

MSDS Documentation

4-Phenylethynylphthalic anhydride (PEPA) MSDS Sheet

Literature and Reviews

-

Diels–Alder cycloaddition polymerization of highly aromatic polyimides and their multiblock copolymers, D. Cristurean et al., Polym. Chem., 12, 3160(2021); DOI: 10.1039/d1py00314c.

-

Improved melt processabilities of thermosetting polyimide matrix resins for high temperature carbon fiber composite applications, H.-Y. Zhang et al., Polymers, 14, 965(2022); DOI: 10.3390/polym14050965.

-

Liquid crystalline thermosetting (LCT) composites based triboelectric nanogenerator with intrinsic flame retardancy, M. Qadeer et al., Adv. Mater. Technol., 7(10), 2200002(2022); DOI: 10.1002/admt.202200002.