Low Price System for Ultra-Clean Surfaces in Minutes

Produce near-atomically clean surfaces without causing damage to your sample

Overview | Specifications | Features | Gallery | Resources and Support

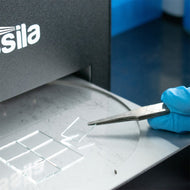

Within minutes, the Ossila UV Ozone Cleaner is capable of removing contamination from the surface of substrates and samples. Using a high-power UV light source to generate ozone and break down organic surface contaminants, you can produce near-atomically clean surfaces without causing any damage to your sample. Volatile compounds created from surface contaminants will quickly evaporate, leaving the sample ready for the next part of your experiment.

The cleaning area has a diameter of 153 mm (6"), providing plenty of space to clean multiple samples at once, microscope slides, or even petri dishes. During cleaning, your delicate samples are protected from overheating as the integrated software monitors the internal temperature and provides readings for the tray, lamp, and electronics.

An essential addition to any lab, our UV ozone cleaner is able to treat a wide range of materials for a number of different applications.

Lightweight Body

Easily moved

High Intensity UV Lamp

Emission at 185 and 254 nm

Safe Design

Including thermal cutoff

Two-Year Warranty

Buy with confidence

Lamp Replacement for Fast Cleaning Times

Our UV ozone cleaner is fitted with a high-quality, long-lasting UV bulb, which provides thousands of hours of high intensity light output. However, every UV bulb has a finite lifetime and lower bulb intensity means increased cleaning times. After prolonged use, a new bulb is the best option to speed up your cleaning process—there's no need to purchase a new system.

When this happens, you can use our UV Lamp Replacement Service. We will replace your bulbs, fully test all components, and safely dispose of your old bulbs. This ensures minimal downtime and maximum lifetime for your equipment.

Specifications

UV Light

Lamp

| Lamp Type | Low pressure mercury discharge lamp |

|---|---|

| Lamp Dimensions (L x D) | 150 mm x 15 mm (5.91" x 0.59") |

| Number of Lamps | 4 |

| Discharge Peaks | 185 nm and 254 nm |

| Lamp Lifetime | T80 lifetime 2,000 hours |

Sample Irradiance

| Sample UV Intensity | 15 mW·cm-2 at 185 nm |

|---|---|

| Cleaning Area | 153 mm (6") diameter |

| Exposure Time | 1 second – 60 minute, digitally controlled |

Dimensions and Weight

| Dimensions (W x D x H) | 210 mm x 310 mm x 228 mm (8.27" x 12.20" x 8.98") |

|---|---|

| Tray Illumination Area | 153 mm (6") diameter circle |

| Maximum Sample Height | 12 mm (0.47") |

| Weight | 5.25 kg |

Materials and Finish

Case

| Material | 1.5 mm (0.06") mild steel |

|---|---|

| Finish | Textured black powder coating |

Drawer Tray

| Material | 1.5 mm (0.06") stainless steel |

|---|---|

| Finish | #4 brushed finish |

User Interface

Display

| Type | 24 bit color TFT LCD display |

|---|---|

| Resolution | 480 x 272 px |

| Size | 4.3" |

Interface

| Description | Tactile buttons |

|---|

Safety Features

Equipment Safety Features

| Drawer Interlock | Hardware interlock sensor |

|---|---|

| Temperature Regulation | Active lamp cooling - 53 CFM axial fan |

| Thermal Cutoff | Onboard temperature sensors for software cutoff |

Power Supply

Input

| Type | IEC C13 power cable |

|---|---|

| Voltage Range | 110 V – 240 V |

| Fuse | 1 A |

Certification and Standards

| Conformité Européenne (CE) Mark |

Low Voltage Directive (2014/35/EU) Electromagnetic Compatibility (EMC) (2014/30/EU) Restriction of Hazardous Substances (RoHS) (2011/65/EU + 2015/863) |

|---|---|

| British Standards Institution (BSI) | BS EN 61010-1:2010 Safety requirements for electrical equipment for measurement, control, and laboratory use. General requirements. |

Documentation

UV Lamp Spectrum (graph of relative intensity of emission spectrum)

UV Lamp Lifetime (graph of relative intensity over operational time in hours)

Declaration of Conformance (Low Voltage Directive, EMC Directive, RoHS Directive, and BS EN 61010-1:2010)

UV Ozone Cleaner Manual (December 2022 onwards)

UV Ozone Cleaner Features

High Intensity UV Lamp

Housing a series of high intensity, low pressure synthetic quartz mercury vapor discharge lamps. By utilizing the emission at 185 nm and 254 nm, ozone is generated. The high intensity output gives results quickly and facilitates a large cleaning area.

Large Cleaning Area

The tray can accommodate wafers up to 153 mm (6") in diameter and 12 mm (0.47") in thickness for a wide array of samples, including:

Simple to Use Interface

The bright LCD display and tactile keypad provide a simple interface.

The integrated software continuously monitors the temperature inside the system and gives readings for the tray, UV lamp, and electronics. This makes it easy to make sure that delicate samples do not overheat.

Designed with Safety in Mind

Our system adheres to BS EN 61010-1:2010 standards alongside EMC, Low Voltage, and RoHS CE directives. Smart safety features include an integrated safety interlock which keeps the lamp off while the tray is open. Plus, a thermal cutoff is triggered if the temperature detected by any of the internal sensors is too high.

UV Ozone Cleaner Gallery

UV Lamp Replacement Service

For safe and successful bulb replacement, simply contact us to place an order for a new bulb and send your Ossila system back to us. Once it arrives in house, we can replace the bulb and have it ready for return within 48 hours. Within this service, we will:

- Replace the UV bulb

- Fully test all components to ensure they are working as intended

- Check that all components meet the required safety standard

- Safely dispose of the old bulb

We recommend bulb replacement is undertaken by us rather than installing the bulb yourself as the system operates at high voltage. Incorrect assembly of the unit after a bulb replacement can be dangerous. Please feel free to contact us if you have any questions about this.

Resources and Support

Which UV Ozone Cleaner Features do I Need?

Which UV Ozone Cleaner Features do I Need?

It is always important to assess the necessity and applicability of additional features in your experimental setup. The Ossila UV Ozone Cleaner is built with simplicity and efficacy in mind.

Read more...