Probe Station

Buy a probe station | Parts & accessories | Key components | Applications | Resources | Technical support

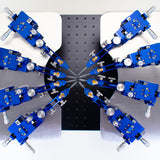

Reject the inflated costs of overengineered systems with a manual probe station that delivers exactly what you need for high-performance, micron-scale probing at a fair price. When set up as an affordable electrical characterization system, you have everything you need to reliably probe, test, and characterize the electrical properties of small-scale electronics.

Ossila probe stations are built to accommodate customization so you can configure a setup that works specifically for you, with Ossila micromanipulators and a suite of electrical characterization tools. The practical and intelligent design of each component means you can prioritize your research instead of being limited by unnecessary complexity.

New Low Prices on Micromanipulators

Buy a Probe Station

Testing Equipment and Accessories

Probing Parts and Accessories

Key Components of a Probe Station

A probe station is a specialized tool designed to help conduct precise electrical measurements on small devices or sensitive materials. At its core, a probe station consists of several key components, which work together with measurement instruments to analyze electrical parameters, enabling highly accurate testing.

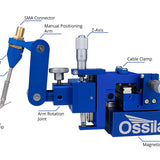

Micromanipulators

Micromanipulators are used to precisely position probe needles on tiny contact points of a sample, often with micron or sub-micron accuracy. Manual micromanipulators offer direct, hands-on control and are widely favored for their intuitive feel, straightforward operation, and lower cost. They provide excellent tactile feedback, allowing researchers to carefully guide probes into position.

The Ossila Micromanipulator provides fine XYZ axis control with a positioning accuracy of 10 µm, ensuring stable and repeatable contact. For even more precise positioning control, the fine pitch Micromanipulators have position accuracy of 5 µm.

Fine-Tipped Probes

Fine-tipped probes are important for making precise contact with the device under test. The probe material affects its mechanical durability and electrical conductivity. Tungsten probes are ideal for repetitive probing and general-purpose DC measurements, thanks to their durability.

Specialized probes are used for advanced measurements including: RF probes for accurate high-frequency device characterization, from MHz to GHz; probe cards for simultaneous testing numerous identical devices; and probes with two electrical contacts for Kelvin probing techniques.

Vibration Isolation

Electrical measurements involving very small contact points, low currents, or high frequencies, are extremely sensitive to mechanical vibrations. External vibrations from lab equipment, foot traffic, or building HVAC systems can cause probe tips to skate across contact pads or damage delicate samples and probes. This leads to noisy data, inaccurate results, and poor repeatability.

High-performance probe stations include built-in elastomeric vibration dampening mounts to stabilize probe contact. The Ossila Probe Station utilizes passive dampening feet, capable of isolating any frequencies above 17 Hz.

Optical Microscope

A microscope provides visual feedback when positioning both the sample and probes. With a long working distance, there is enough space between the lens and the sample for the micromanipulators. Stereo microscopes are commonly used in probe stations. However, digital microscope systems offer more comfortable viewing, higher user safety and ability to capture images during probing.

Monocular zoom lens systems coupled with digital cameras display a high-magnification image directly onto a monitor. This setup is ideal for long experiments and shared viewing. It also improves operator safety when testing active optoelectronic devices such as LEDs or lasers, as it prevents direct eye exposure to the magnified emitted light.

Wafer Chuck

The wafer chuck acts as the stable platform for the device under test. Its characteristics, such as the diameter, flatness, and planarity, directly impact the quality and type of measurements possible. These specifications are key to ensuring consistent probe contact across your sample. However, overengineering of these chucks can significantly increase probe station costs.

Vacuum chucks hold samples in place by applying a vacuum to holes or grooves on the chuck surface. They can be electrically insulating, used when you need to electrically isolate the device under test.

Positioning Stage

The positioning stage moves the sample chuck, allowing for precise alignment of the device under test relative to the probes. Movement in three linear axes – X, Y (for planar movement across the sample) and Z (for vertical adjustment to make or break probe contact) – and a rotational (theta) axis for fine angular alignment of the sample make sample positioning and contact easy.

Offering direct, hands-on adjustment via micrometers, manual stages are ideal for simpler setups or when frequent, varied adjustments are needed. Key performance characteristics of a stage include its travel range, positioning resolution, repeatability, and stability.

Probe Station Applications

Probe stations are integral in fields like semiconductor manufacturing, electronics research, telecommunications, and automotive and aerospace industries. Whether you're working with compound semiconductors, organic and flexible electronics, thin film devices, photodetectors and sensors, or emerging materials, our probe station products support a range of testing setups.

Wafer-Level Testing

Probe stations are essential for wafer-level testing in fields like semiconductor manufacturing. Before a wafer is diced into individual chips, it undergoes testing to assess the performance of each die. This early-stage testing helps manufacturers identify faulty dies, reducing waste and improving overall production efficiency.

Failure Analysis

When a device malfunctions, a probe station can be used to pinpoint the root cause of the failure. By systematically probing different parts of the device, engineers can identify defective components or faulty connections. This information is crucial for improving future designs and manufacturing processes.

Research and Development (R&D)

In R&D environments, probe stations are used to test new materials, device structures, and fabrication processes. Researchers can use them to explore the electrical properties of novel materials like organic semiconductors, 2D materials, and nanostructures.

Device Characterization

Probe stations are also used to measure a wide range of electrical parameters, including DC characteristics like current-voltage (I-V) curves and capacitance-voltage (C-V) curves, as well as RF characteristics such as S-parameters. By analyzing these measurements, engineers can gain insights into the device's performance, reliability, and suitability for specific applications.

Optoelectronic Testing Stations

In addition to electrical testing, probe stations can be used to test optoelectronic devices, such as photodiodes, LEDs, and laser diodes. By integrating optical sources and detectors into the setup, engineers can measure the performance of devices that interact with light, which is crucial for applications in fiber optics, solar cells, and display technologies.

Life Sciences

These instruments are also crucial in electrophysiology, where they are used to position microelectrodes with extreme precision to record electrical activity from individual neurons or muscle cells. This allows researchers to study ion channel behavior, synaptic transmission, and neural circuitry in real-time. In cell biology, micromanipulators are used for various tasks, such as injecting biological molecules into cells, performing patch-clamp experiments, or isolating specific cells for further analysis. They are also employed in genetic engineering for microinjection of DNA or RNA into embryos or cells, and in microdissection to manipulate or dissect small tissue samples under a microscope.

Resources

About Our Equipment

Connecting the Micromanipulator to the Source Measure Unit

Connecting the Micromanipulator to the Source Measure Unit

This guide gives an overview of how to use the Ossila Micromanipulators with the Source Measure Unit, as well as some general tips and tricks for getting the most out of sensitive electrical probing measurements.

Read more... Micromanipulator Drift and Other Common Errors

Micromanipulator Drift and Other Common Errors

The performance of a micromanipulator can suffer from various mechanical issues, including drift, backlash, side play, and sticking. Understand these issues and how our engineers have implemented solid design principles to avoid potential movement issues from the start.

Read more... What Features Do You Need in a Probe Station?

What Features Do You Need in a Probe Station?

Probe stations are incredibly useful for a wide range of experiments, from semiconductor characterization to electrophysiology. However, each experiment will have different requirements and every lab has its own demands. This raises the question: what probe station features do you need?

Read more... Getting the Most Out of Your Ossila Micromanipulator

Getting the Most Out of Your Ossila Micromanipulator

This guide is designed to help you set up, connect, and tailor your Ossila Micromanipulator to your specific research needs. We believe that precision instruments should provide intuitive control, and our goal is to help you achieve that. Whether you are performing an initial setup or advanced modifications, we are here to support you.

Read more...Electronics Resources

Minimizing electrical resistance is a key consideration when selecting components for use in probe stations. Lower resistance allows current to flow more easily through the probes to the measurement device, without affecting the measurement itself. There are multiple things that can contribute to resistance in measurement devices.

Read more...Leakage current refers to any unwanted current that flows outside of the desired circuit path, adding to the noise of a measurement. Leakage currents can arise from many things, such as:

Read more...For many electrical measurements, the cable that connects your instrument to your device is a simple wire. But when you are working at the limits of sensitivity—measuring picoamps of current, sourcing from gigaohm impedances, or capturing fleeting signals—your choice of cable becomes a critical part of your experimental setup.

Read more... Semiconductor Characterization Methods for Materials and Devices

Semiconductor Characterization Methods for Materials and Devices

Semiconductor characterization refers to the process of measuring and evaluating the properties of a semiconductor. This is quite a broad term and can refer to different processes depending on the context. It can refer to:

Read more...Technical Support