Start Automating Your Coating Process with the Ossila Spin Coating System

Combine spin coater uniformity with syringe-pump controlled deposition for automated, repeatable thin film fabrication.

Overview | Specifications | Features | Gallery | In the Box | Accessories | Resources and Support

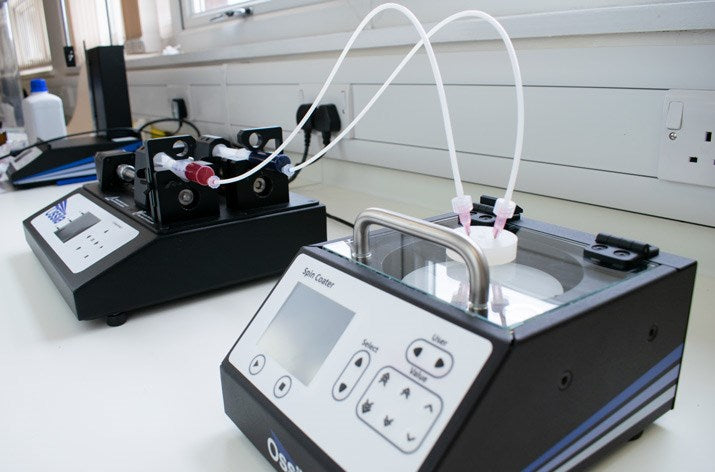

The Ossila Spin Coating System combines a spin coater and syringe pump, with a connection adapter, disposable syringes, PTFE tubing, and needles - everything you need to improve your spin coating. This system allows you to combine the uniformity and easy optimization of the Ossila spin coater, with the precise deposition of an Ossila syringe pump. This saves users time and stress during labour-intensive depositions, while making experiments more repeatable and minimizing human error.

Up to four different solutions can be dispensed separately, great for layer-by-layer spin coating, antisolvent quenching or any other complex processing technique. Standard manual dispensing can still be carried out too, without needing to remove the adapter.

The bundle comes with a multi-substrate chuck and is available with any combination of our syringe pump and spin coater models. Choose the right system to fit your research needs and start automating your spin coating process.

Two-Year Warranty

Buy with confidence

Universal Syringe Clamps

For 0.5 μl to 60 ml syringes

Full Control

Save recipes with up to 50 steps

Compact and Lab Proof

Durable and solvent-safe

Spin Coater Specifications

| Standard V3 (L2001A3) | Advanced V1 (L2001B1) | Advanced V2 (L2001B2) | |

|---|---|---|---|

| Speed Stability | <2% error | <0.25% error | <0.25% error |

| Speed | 120 – 6,000 rpm | 500 – 10,000 rpm | 500 – 10,000 rpm |

| Acceleration Control | No | No | Yes |

| Deceleration Control | No | No | Yes |

| Maximum Acceleration | N/A | N/A | 4000 rpm/s |

| Maximum Deceleration | N/A | N/A | 700 rpm/s |

| Minimum Acc/Dec | N/A | N/A | 10 rpm/s |

| Spin Time | 1 – 1,000 sec | 1 – 3,600 sec | 1 – 3,600 sec |

| User Profiles | 10 | 10 | 10 |

| Programs per User | 10 | 15 | 15 |

| Materials | Polypropylene bowl, steel casing, tempered glass lid | PTFE bowl, powder coated steel casing, tempered glass lid | PTFE bowl, powder coated steel casing, tempered glass lid |

| Weight | 2.75 kg | 3.7 kg | 3.7 kg |

Additional Specifications

| Max Substrate Size | 100 mm (4") diameter |

|---|---|

| Programs | 10 programs, , with up to 50 steps each, on each user profile |

| Safety Switch | Magnetic safety switch on the door |

| Additional Features | Built-in spirit level and adjustable feet |

| Dimensions (D x W x H) | 225 mm x 170 mm x 140 mm (8.86" x 6.69" x 5.51") |

| Power Supply | DC 24 V 2 A, via 100–240 V 50/60 Hz power adapter |

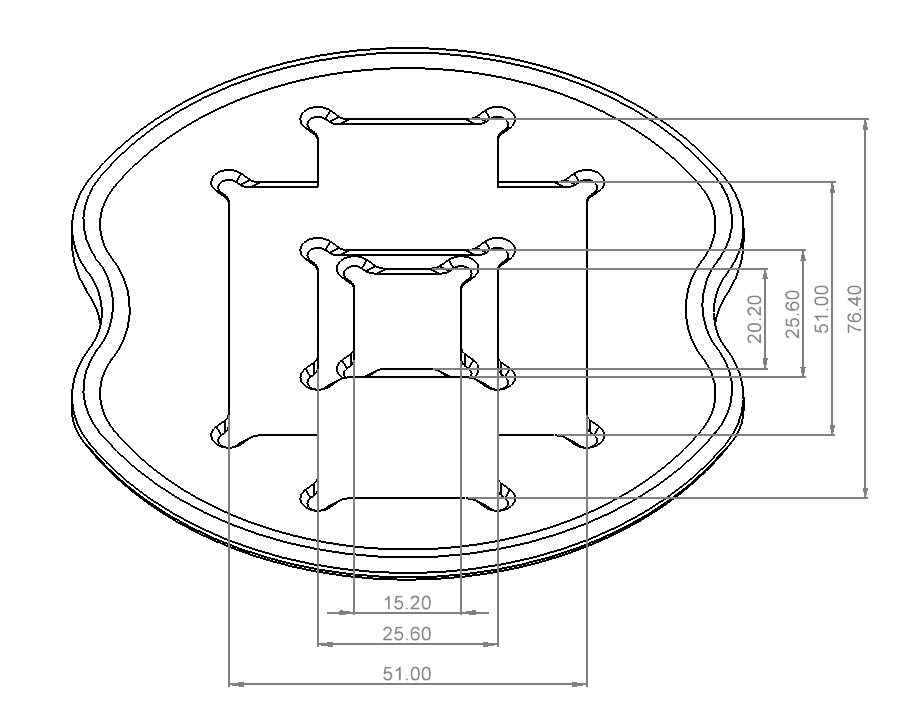

Spin Coater Chuck Specifications

L2001U1/L2001U2 Standard Spin Coater Chuck

Choose between polypropylene, PTFE, or PEEK chuck material depending on your application. The design incorporates all of the most commonly used substrates including:

Plus, our chucks also have:

- A rimmed edge to improve air flow uniformity and reduce solvent build up within the bowl.

- Simplified drainage channels to reduce buffeting and improve the stability of the chuck.

- Finger cutouts for easy removal of chucks, allowing you to switch them for different experiments.

Custom Chucks

Custom chucks are available at a discounted price with the purchase of a spin coater, but can also be purchased separately. Please contact us to discuss your needs, specifying the length, width, and height of each substrate. Alternatively, STL, STEP, and SLDPRT files (for AutoCAD / FreeCAD and SolidWorks respectively) are freely available to download should you wish to create your own chucks.

Custom Chuck Requirements

| Maximum Chuck Diameter | 115 mm |

|---|---|

| Maximum Substrate Diameter | 100 mm (4") |

Blank Chuck Downloads

Version 2

Version 1

- .STL file for AutoCAD and TurboCAD

- .SLDPRT file for SolidWorks

Manual

Spin Coater Advanced user manual

Syringe Pump Specifications

| Single Syringe Pump | Dual Syringe Pump | |

|---|---|---|

| Syringe Channels | 1 | 2 |

| Channel Dependency | N/A | Independent channel control |

| Overall Dimensions (W x H x D) | 240 mm x 150 mm x 150 mm (9.8" x 6.1" x 6.1") |

240 mm x 150 mm x 260 mm (9.8" x 6.1" x 10.2") |

Additional Specifications

| Operation Modes | Infusion and withdrawal |

|---|---|

| Minimum Syringe Size | 0.5 μl |

| Maximum Syringe Size | 60 ml |

| Safety Features | Limit switches, crashing sensing |

| Power | 24 V DC, 2.0 A |

| Power Supply Input Voltage Range | 100 – 230 V, 50/60 Hz, 50 VA |

| Operating Temperature | 5 °C – 40 °C (41 °F – 104 °F) |

| Operating Humidity | Up to 80% RH at 31 °C (87.8 °F) |

Motor

| Motor Type | NEMA 17 stepper motor |

|---|---|

| Step Angle | 1.8° |

| Steps per Full Revolution | 200 |

| Screw Pitch | 1 mm |

| Travel per Step | 5 µm |

| Maximum Linear Force | 500 N |

Driver

| Micro Stepping | 1/128 |

|---|---|

| Micro Steps per Revolution | 25,600 |

| Maximum Speed | 1,000 steps.s-1; 5mm.s-1; 300mm.min-1 |

| Minimum Speed | 0.015 steps.s-1; 75nm.s-1; 4.5µm.min-1 |

| Rate Accuracy** | ±0.16% |

** The Ossila Single Syringe Pump has a stepping accuracy of 0.16%, which gives a rate accuracy of 19 nm.s-1. In practice, the accuracy of the flow rate from a syringe pump depends on the accuracy of the driver and the syringe diameter. Different syringes have different manufacturing tolerances. The diameter of plastic disposable syringes can vary by up to 3%, resulting in an error in dispense rate of up to 6%. Glass and stainless steel syringes have a higher tolerance, with a maximum of 0.5% variation in the internal diameter and volume error of up to 1%.

Software

| Number of Programs | 10 |

|---|---|

| Steps per Program | 100 |

| Syringe Size Settings | 5 pre-sets, 1 customizable diameter |

| Force Tuning | 5% – 100% (5% increments) |

| Memory | Non-volatile memory |

Syringe Compatibility

Maximum and Minimum Flow Rate

The maximum and minimum flow rate of the syringe pump is determined by the stepping rate of the motor and the diameter of the syringe. Maximum and minimum flow rates for some common syringe sizes are shown below. By choosing the correct syringe diameter, it is possible to achieve a range of dispense rates spanning 8 orders of magnitude.

| Syringe Volume | Syringe Diameter | Minimum Flow Rate | Maximum Flow Rate |

|---|---|---|---|

| 0.5 µl | 0.103 mm | 0.6 pl.s-1 (2.1 nl.hr-1) | 42 nl.s-1 (0.15 ml.hr-1) |

| 10 µl | 0.46 mm | 12.5 pl.s-1 (45 nl.hr-1) | 0.8 µl.s-1 (3 ml.hr-1) |

| 100 µl | 1.46 mm | 0.1 nl.s-1 (0.36 µl.hr-1) | 8.4 µl.s-1 (29.8 ml.hr-1) |

| 1 ml | 4.61 mm | 1.3 nl.s-1 (4.7 µl.hr-1) | 84 µl.s-1 (298 ml.hr-1) |

| 5 ml | 10.3 mm | 6.3 nl.s-1 (22.7 µl.hr-1) | 0.4 ml.s-1 (1.5 l.hr-1) |

| 50 ml | 32.6 mm | 62.6 nl.s-1 (225 µl.hr-1) | 4.2 ml.s-1 (15 l.hr-1) |

Product Certification and Standards

| CE |

Machinery Directive 2006/42/EC EMC Directive 2014/30/EU RoHS Directive 2011/65/EU |

|---|---|

| UKCA |

Supply of Machinery (Safety) Regulations Electromagnetic Compatibility Regulations Restriction of the Use of Certain Hazardous Substances in Electrical and Electronic Equipment Regulations |

| International Standards | BS EN ISO 12100:2010 Safety of Machinery - General Principles for Design - Risk Assessment and Risk Reduction |

User Manual

Single Syringe Pump user manual

Spin Coating System Features

Built-In Software

No external PC required, both the Syringe Pump and Spin Coater feature built-in software which allows multi-step programs (20 programs with a total of 99 steps on the syringe pump and 10 on each profile on the spin coater, with up to 50 steps each) to be created and saved with ease.

Complete Control

Take your spin coating to the next level. Together, the Spin Coater and Syringe Pump give you complete control over the spin speed and the solution dispense rate and volume, with a high degree of precision. Easily and accurately reproduce your experiments every time.

More Applications

There are many thin film applications that require more precise control over solution deposition. When anti-solvent quenching, it is important to allow a precise amount of time to pass after the initial solution before adding the solvent. Similarly, for synthesizing multilayered structures, a dual pump syringe pump is invaluable.

Multiple Modes of Operation

You can use the spin coater and syringe pump together with the supplied adapter, or as separate units for any experiment that only requires one or the other. In addition, each syringe pump on the dual pump model can be controlled completely independently of the other.

Large Range of Spin and Flow Rates

With spin speeds from 120 rpm to 10,000 rpm across our spin coater range and syringe pump flow rates from 2.1 nl.hr-1 to 15 l.hr-1, take complete and precise control of your thin film processes.

Compact and Lab-Proof

The compact design along with the high quality, durable, and solvent-safe construction of the two units make them suitable for busy labs and glove boxes. Since the spin coater is not burdened by a vacuum pump, it is easy to move from place-to-place to make room when space is limited.

Spin Coating System Gallery

In the Box

- Spin coater

- Single or dual syringe pump

- Spin coater adapter

- Multi-substrate chuck

- Fifteen 5 ml Norm-Ject Disposable Luer Lock Syringes

- Five lengths of PTFE tubing with Luer Lock adapters

Accessories and Related Products