An Effective Glove Box System for Your Laboratory

Automated purge cycles with continuous sensor feedback

Overview | Specifications | Features | Gallery | Resources and Support

Easily create and maintain a low oxygen and moisture environment with this benchtop glove box. Handling, processing, and storing air sensitive samples, for chemistry and other inert atmosphere processing applications, is simple and convenient.

Achieve oxygen levels as low as 0.5% and water levels as low as 0.1% relative humidity, then focus on your experiments and let the glove box handle the purging. Sophisticated software and high accuracy sensors trigger specially designed purge cycles and leak tests for extensive control with minimum effort. With a leak rate of less than 0.25% volume per hour, your chemicals, materials, and samples are safe for extended periods of time.

Implement inert conditions in more of your experiments with universal feedthroughs for power, vacuums, and more. Once up and running, protect your experiments and reduce the need for a full system purge with live antechamber data and antechamber-specific purges.

ISO Class II Leak Rate

Ultra-low at <0.25% vol/hour

Automated Purging

Lower operational costs

Live Sensor Feedback

With high accuracy readings

Antechamber Access

Protect your inert environment

How Effective is this Glove Box?

Delivering high-performance inert conditions, the Ossila Glove Box achieves oxygen levels below 0.5% and moisture levels as low as 15 ppm.

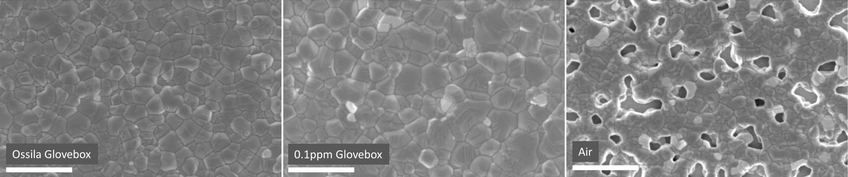

When fabricating perovskite thin films, we found no significant difference in device performance between films produced in our glove box and those made in a considerably more expensive, slightly higher specification system. The Ossila-produced devices achieved an impressive 19.2% champion efficiency, coming close to the 19.7% efficiency achieved with 0.1 ppm conditions. SEM images confirm the both resulting perovskite films were nearly identical, and were drastically improved compared to films made in air.

As an ISO class II system with a leak rate of less than 0.25% vol/hour, the Ossila Glove Box provides robust inert conditions that are more than sufficient for most research and development needs. For a fraction of the price, it is a smart, cost-effective choice without sacrificing quality or results.

Specifications

| Leak Rate* | <0.25% vol/hour (ISO Class II) |

|---|---|

| Maximum Input Pressure | 2 bar |

| Working Overpressure Range | 0.1 mbar – 5 mbar |

| Purge Overpressure Range | 10 mbar – 15 mbar |

*For an inert atmosphere system, a leak rate of between 0.05 to 0.5% of box volume per hour is sufficiently low.

Automated Purge Cycles

Automated Purging

When active, the system will purge as needed to maintain low oxygen and water levels without excessive use of inert gas.

Leak Test

Quickly and accurately identify leaks by monitoring the internal pressure through a simple, pre-programmed leak test.

Quick Purge

Circulate fresh gas for a short period of time to maintain a clean environment, even if monitored levels are unchanged.

Initial Purge

After installation or significant exposure, achieve desired moisture, oxygen, and pressure levels within 24 hours.

Circulation Purge

An automated short circulation purge once a day keeps the system fresh. Customize the time to suit your lab.

Antechamber Cycle

Start an antechamber purge easily to ensure bringing materials into or out of the glove box is safe and simple.

Environmental Sensors

| Oxygen Sensor Range | 0.5% – 25% |

|---|---|

| Oxygen Sensor Resolution | 0.01% |

| Moisture Sensor Range | 0% relative humidity – 100% relative humidity |

| Moisture Sensor Resolution | 0.1% relative humidity (15 ppm) |

| Pressure Sensor Range | 300 mbar – 1200 mbar |

| Pressure Sensor Resolution | 0.005 mbar |

| Temperature Sensor Range | 40 °C – 120 °C |

| Temperature Sensor Resolution | 0.1 °C |

Dimensions

| Main Chamber, External (D x W x H) | 500 mm x 750 mm x 500 mm (19.7" x 29.5" x 19.7") |

|---|---|

| Main Chamber, Internal (D x W x H) | 450 mm x 600 mm x 500 mm (17.7" x 23.6" x 19.7") |

| Antechamber, Internal (D x W x H) | 150 mm x 150 mm x 150 mm (5.9" x 5.9" x 5.9") |

| Weight | 33.85 kg (74.63 lbs) |

Built for Every Laboratory

Monitor Internal Conditions

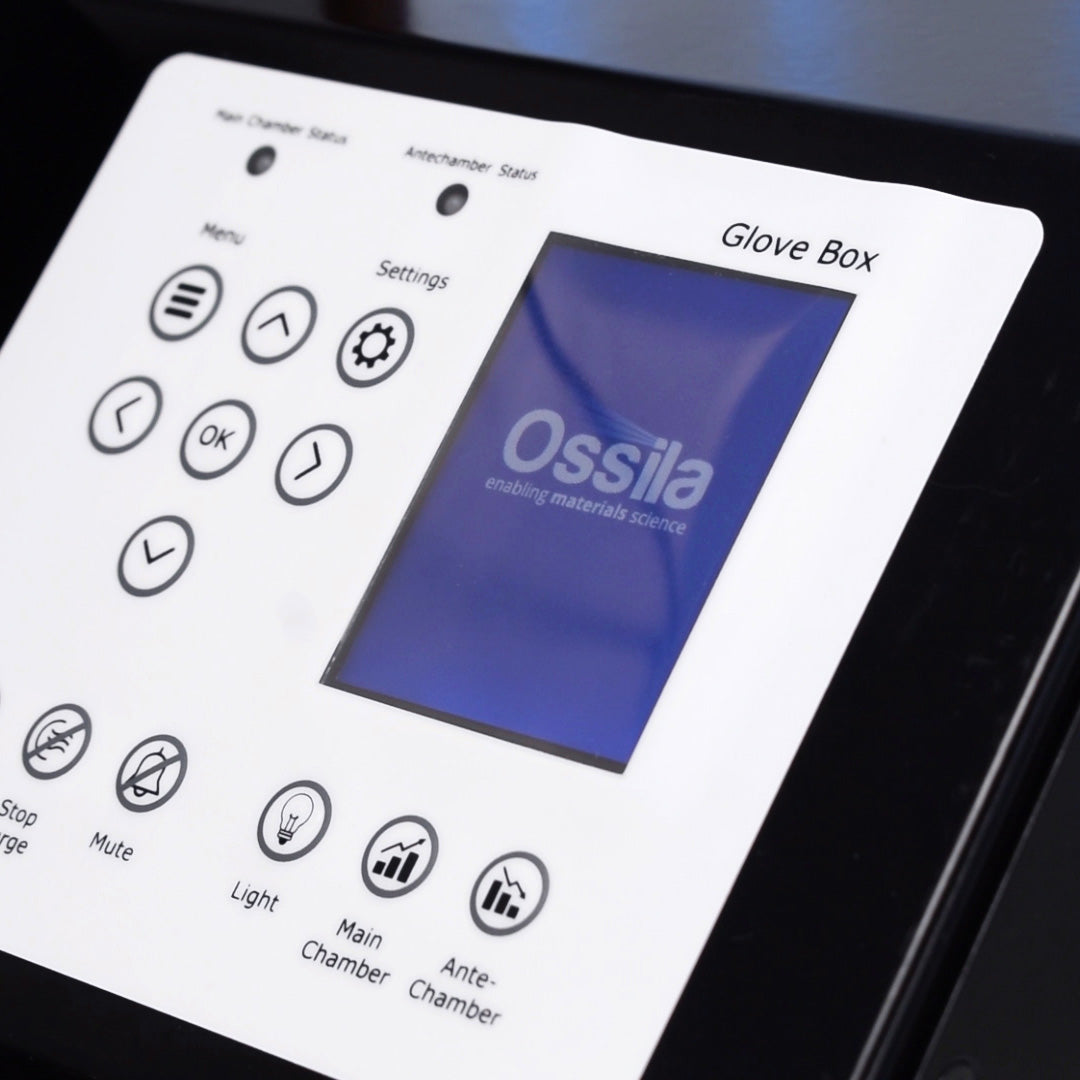

Guarantee your inert environment with precision sensor boards which track real-time oxygen, moisture, pressure, and temperature levels. Using the high accuracy readings, automated purge cycles respond to environmental changes so you can stay focused on your work with full confidence that your samples are protected.

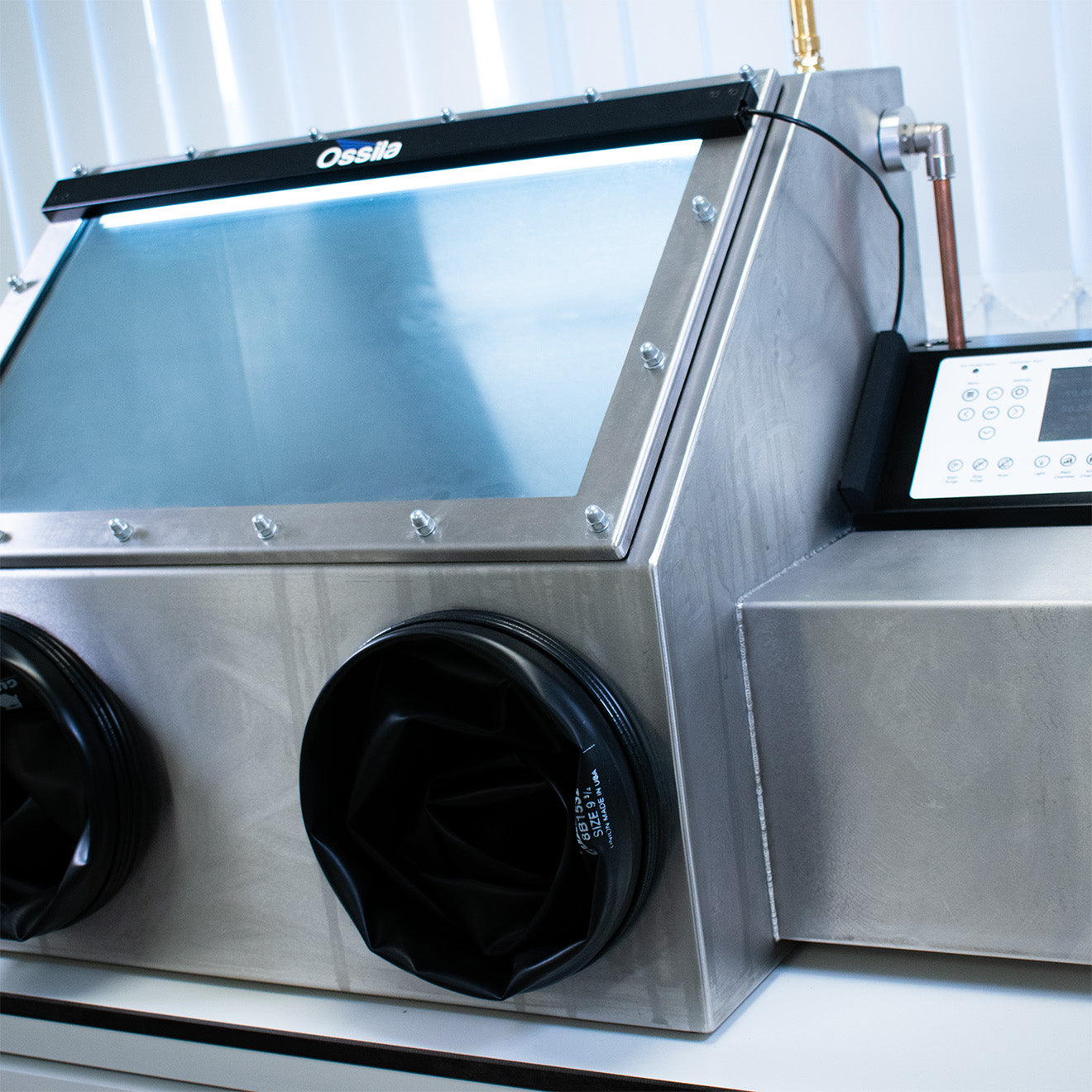

Lower Ingress than Acrylic

Choose a glove box built for performance and integrity. Grade 304 stainless steel, 6 mm hardened glass, and butyl rubber gloves ensure ultra-low moisture and oxygen ingress rates, exceeding acrylic alternatives. Designed to withstand frequent, long-term use, you can safely work with a range of materials in many applications.

Cheap to Run

Set up a reliable inert environment without a huge initial investment or high maintenance costs. Compared to larger systems, low ingress rates and a small volume significantly reduce the amount of gas you need to protect your samples and processes.

Universal Feedthroughs

Expand your experimental possibilities and set up a range of equipment inside the glove box. Easily connect power, communication lines, or vacuum systems, without compromising the controlled environment, using the two universal KF 40 flange feedthroughs.

Easy-To-Use Software

Customize and monitor your inert environment with the integrated software. It is easy to set your desired conditions, measure oxygen and moisture levels, trigger or schedule a purge, confirm when the antechamber is safe to open, test for leaks, and check if the system is still running at the desired overpressure.

Glove Box Gallery

Additional Specifications

Materials

| Box and Antechamber | 2 mm (0.08") graded 304 stainless steel, 2B surface finish |

|---|---|

| Window | 6 mm (0.24") hardened glass |

| Gloves | 2 x butyl rubber gloves, 8" diameter |

Other Features

| Feedthroughs | 2 x DN 40 ISO-KF blanked feedthroughs |

|---|---|

| Gas Inlet / Exhaust* | 12 mm (0.47") push-fit connector (PTFE recommended) |

| Gas Inlet Requirements | 99.99% N2 purity, inlet pressure (1 bar to 2 bar) |

| Safety Features | Software control of maximum pressure, 500 mbar blow off valve |

| Lighting | Internal LED white light |

| Power Supply | 24 V DC |

*The exhaust does not have filtration and so should be exhausted into a fumehood or exhaust stack of the building.

Documents and Datasheets

Purge Time Graph (Representative graph of the purge time for the main chamber)

Leak Rate Tests (representative graph of the leak rate of a system, JPG)

Declaration of Conformance (EMC Directive, RoHS Directive)

Ossila Glove Box User Manual (PDF)

Resources and Support

Why Buy the Ossila Glove Box

Why Buy the Ossila Glove Box

Our system is robust, affordable, and easy-to-use. It creates an inert environment suitable for many applications.

Read more... How to Choose a Glove Box

How to Choose a Glove Box

Consider these six factors to choose the most suitable system for your samples, experimental needs, budget, and lab environment.

Read more...