Inert Atmosphere Processing

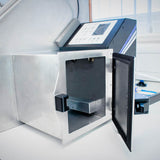

Our glove box is a complete benchtop system designed with affordability and simplicity in mind. Ideal for many inert atmosphere applications, from air sensitive experiments to handling hazardous materials and chemicals. With a comprehensive and versatile suite of integrated features, our glove box is built for every laboratory, including yours.

We also supply a range of replacement components, including gloves and sensors, to make system maintenance straightforward and easy. And if you need support, our resources provide troubleshooting tips, application guidance, and maintenance advice.

Together, we offer everything you need to easily incorporate an effective Ossila Glove Box system into your laboratory set up.

Jump to: Browse equipment | Inert atmosphere applications | What is a glove box? | Resources and support

Browse Inert Atmosphere Processing Equipment

Inert Atmosphere Applications

Working with Oxygen/Moisture-Sensitive Materials

Many chemicals, samples, and experiments require an oxygen-free or low-humidity environment to avoid degradation. Inert atmosphere processing systems allow you to handle these materials without exposing them to air.

Hazardous Substance Isolation

Some inert atmosphere systems provide a physical barrier to contain or isolate dangerous gases, powders, or other hazardous materials that could be harmful if released into the lab. This protects both the researcher and the surrounding environment. These are know as isolation systems.

Contamination Prevention

An inert, isolated atmosphere can also protect sensitive samples or experiments from outside contaminants like dust or moisture. This is crucial for things like semiconductor fabrication, protein crystallization, and other precision applications. Equipment for these purposes are known as contamination systems.

What is a Glove Box?

A glove box creates a stable, sealed environment. Samples are transferred into the main chamber through an antechamber, and gloves enable you work within the inert environment.

Within a glove box, you can handle sensitive or reactive materials without exposing them to the open air. This makes them an essential piece of equipment used in many areas scientific research.

Some important features of a glove box include:

-

The box is sealed as much as possible to isolate samples from the outside atmosphere. The glove box is usually filled with an inert gas that will not react with other materials.

-

The researcher interacts with the contents of the box using gloves built into the walls of the glove box.

-

Materials and equipment can be moved into or out of the glove box using an antechamber.

Glove boxes come in a variety of sizes, from small benchtop units (like the Ossila Glove Box) to large units with complex filtration systems. They are typically made of robust metals, like steel, with a transparent window so the researcher can see what they are working with. This window is often made from acrylic or tempered glass. The gloves are usually made of materials like butyl rubber that provide dexterity, with as little leaking as possible.

Resources and Support

Buying Guides

Why Buy the Ossila Glove Box

It is important for you to understand the benefits and limitations of different inert atmosphere systems before making the investment. If you are looking for a robust, easy-to-use system, the Ossila Glove Box is the perfect choice for you.

Learn more... How to Choose a Glove Box

How to Choose a Glove Box

Choosing the right glove box for your needs is important. The system should be suitable for your samples, experimental requirements, laboratory environment, and budget.

Read more... Designing a Glove Box

Designing a Glove Box

There are several important components to consider when designing a glove box. Importantly, they should be designed to reduce leakage as much as possible.

Read more...Maintenance and Operation

Standard Operating Procedure of a Glove Box

Standard Operating Procedure of a Glove Box

Working safely within a glove box requires the care and co-operation of everyone who uses it. For this reason, we recommend outlining a standard operating procedure for your laboratory.

Read more... Installing Your Glove Box

Installing Your Glove Box

The Ossila Glove Box is designed to be easy to install and maintain, and is suitable for most laboratories. Its small footprint and quick set up also means that it is relatively portable and can be conveniently transferred between labs as required.

Read more... How to Replace Glove Box Gloves

How to Replace Glove Box Gloves

Glove box gloves must be flexible and relatively thin to allow movement within the main chamber. This will be the most vulnerable exposure point to air and moisture as small holes can easily occur here.

Read more... Outgassing Materials and Solvents

Outgassing Materials and Solvents

Materials processed within a glove box can directly impact the quality of the atmosphere and the ability of the system to maintain an inert atmosphere.

Read more...Maintenance and Troubleshooting: Glove Boxes

There are a number of steps that you as the glove box user can take to ensure that the inert atmosphere remains intact.

It is also important to be able to quickly identify, troubleshoot, and fix problems as they occur.

Learn more... Feedthrough Assembly for Your Glove Box

Feedthrough Assembly for Your Glove Box

Feedthrough points allow you to pass lines and cables from the external to the internal environment. There are several different ways to create the required feedthroughs in your glove box.

Read more... Antechamber of a Glove Box

Antechamber of a Glove Box

Antechambers are small, isolated compartments. They can be exposed to atmosphere more often than the main chamber as it will take them much less time to achieve inert conditions. You will use these to move small items in and out of your glove box.

Read more... Performing Glove Box Leak Tests

Performing Glove Box Leak Tests

If you suspect a leak, the first thing you should do is perform a leak test. Leak tests raise the glove box to an extreme positive or negative pressure and then measure the rate of change of pressure over a period of time.

Read more... Leaks in a Glove Box

Leaks in a Glove Box

Our glove boxes run at an overpressure, so if the leak is small, the glove box may still be able to maintain the integrity of the internal atmosphere. However, during this time, the glove box will use a much larger amount of inert gas than normal as the overpressure in the glove box will result in a flow of gas from the inside of the system to the outside.

Read more...Theory and Applications

How to Make a Perovskites Solar Cells in a Glove Box

This video is a guide on how to make perovskite films when processed inside a nitrogen filled glove box. The resultant devices achieve efficiencies greater than 19% PCE.

Learn more... Applications of Glove Boxes

Applications of Glove Boxes

A glove box is suitable for a variety of applications across the world of science and research. From organic electronics to additve manufacturing, the inert atmosphere provided by a glove box is critical in many settings.

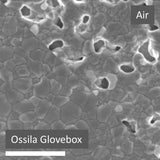

Read more... Case Study: Perovskite Solar Cells in a Glove Box

Case Study: Perovskite Solar Cells in a Glove Box

The highest performing perovskite solar cells were all made in glove boxes. This case study to investigate how inert does an environment need to be for a given process and is the Ossila Glove Box effective.

Read more...Film and device encapsulation involves applying thin protective layers onto the surface of your electronic devices. Encapsulating your devices inside a glove box environment limits their exposure to contaminants

Read more... Inert Gases

Inert Gases

Inert gases are gases which are chemically inactive, so will not undergo chemical reactions with many materials. Inert gases are used for many purposes in a wide range of industries - for example in welding, chemical processing, and as filler gases in light sources.

Read more...Defining Moisture Content in a Glove Box

There are multiple ways of defining how much moisture is present in the air. With clear definitions, guidance on converting values, and a simple conversion table, you will easily be able to work with any of the available definitions to control the moisture content in your glove box environment.

Learn more... Argon vs Nitrogen for Glove Box

Argon vs Nitrogen for Glove Box

Argon and nitrogen are both unreactive gases which can be used to create an inert environment within a glove box. Both gases will efficiently displace air within a confined space, are easy to store and will not react with most materials. Therefore, both N2 and Ar can create a glove box environment with very low moisture and oxygen levels.

Read more... Positive vs Negative Pressure in a Glove Box

Positive vs Negative Pressure in a Glove Box

Glove boxes can be maintained at positive pressure or negative pressure. Both create atmospheres separate from ambient, keeping a barrier between your materials and the external lab environment.

Read more... Air Sensitive Compounds

Air Sensitive Compounds

Some materials can degrade or decompose over time due to exposure to oxygen or moisture. This can be accelerated by exposure to light or increased temperatures. Other materials can absorb moisture from the air causing them to aggregate.

Read more... Air Free Techniques

Air Free Techniques

Air free techniques are essential for the handling and storage of materials that are unstable when exposed to air. Compounds are defined as unstable if they react with an element in air, often moisture or oxygen.

Read more...