What Features Do You Need in a Probe Station?

Jump to: Probe Station Uses | Automatic vs. Manual | Chucks and Stages | Shielding and Enclosures | Digital Or Stereo Microscope | Vibrational Damping

Probe stations are incredibly useful for a wide range of experiments, from semiconductor characterization to electrophysiology. However, each experiment has different requirements and every lab has its own demands. This raises the question: what probe station features do you need?

As well as experimental needs, it is important to consider available lab space, budget and experimental versatility. Therefore, an equally important question when selecting a probe station is what features are worth the expense.

Probe Station

Matching Your Probe Station To Your Application

The first thing to consider when choosing a probe station is its intended application or use, as this will determine some of its requirements.

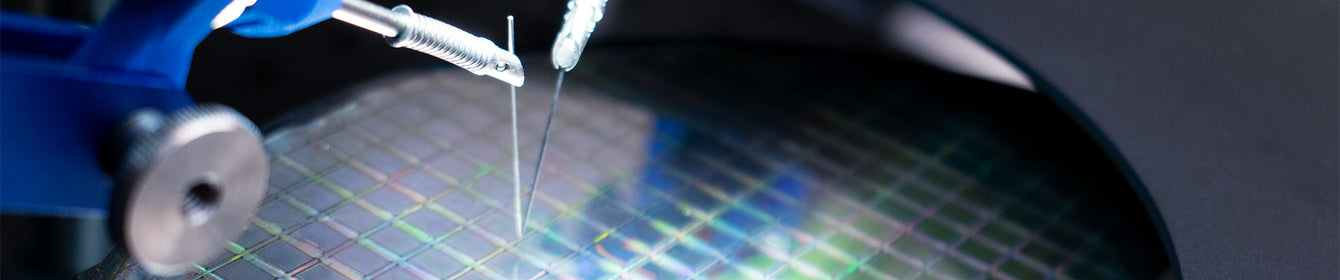

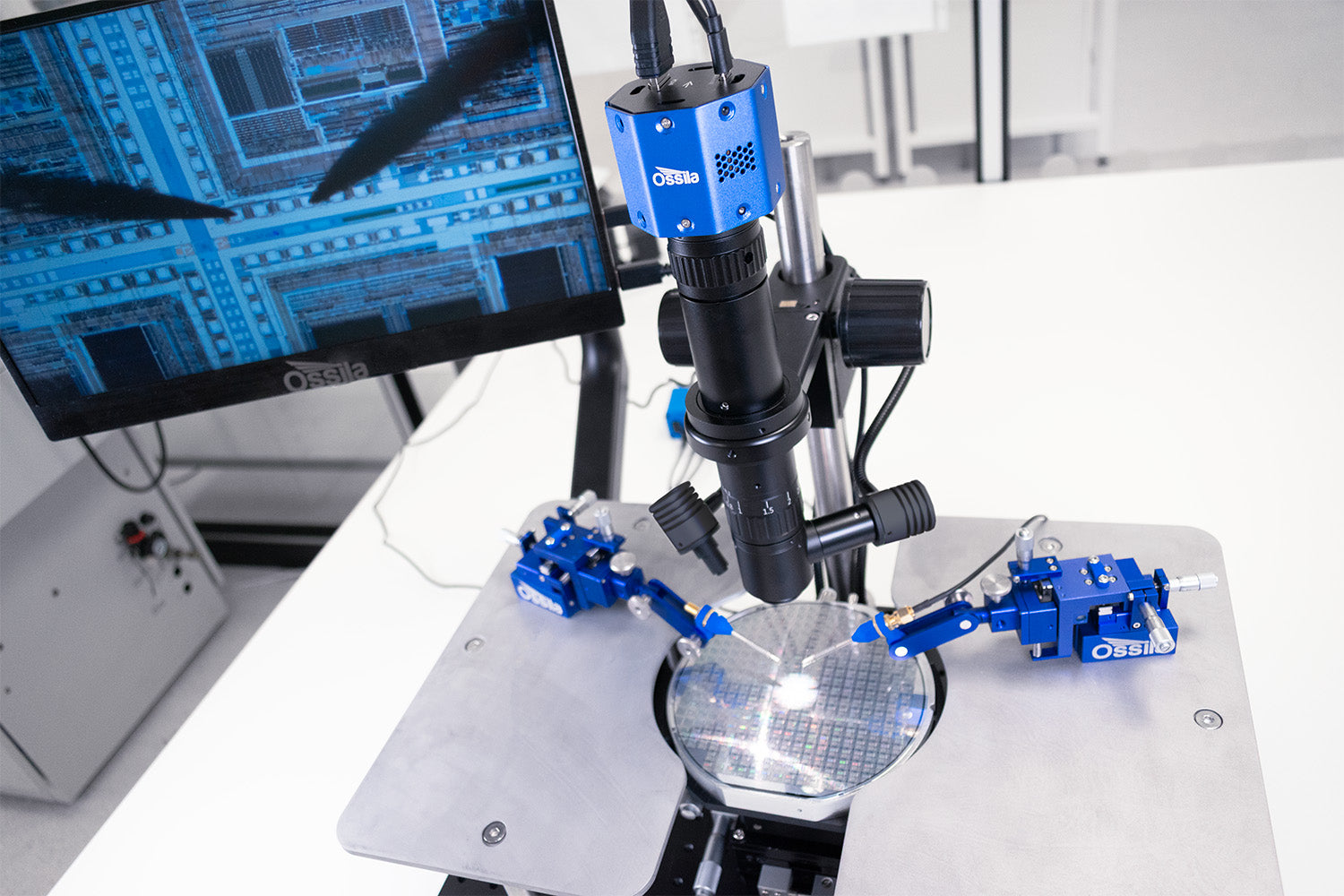

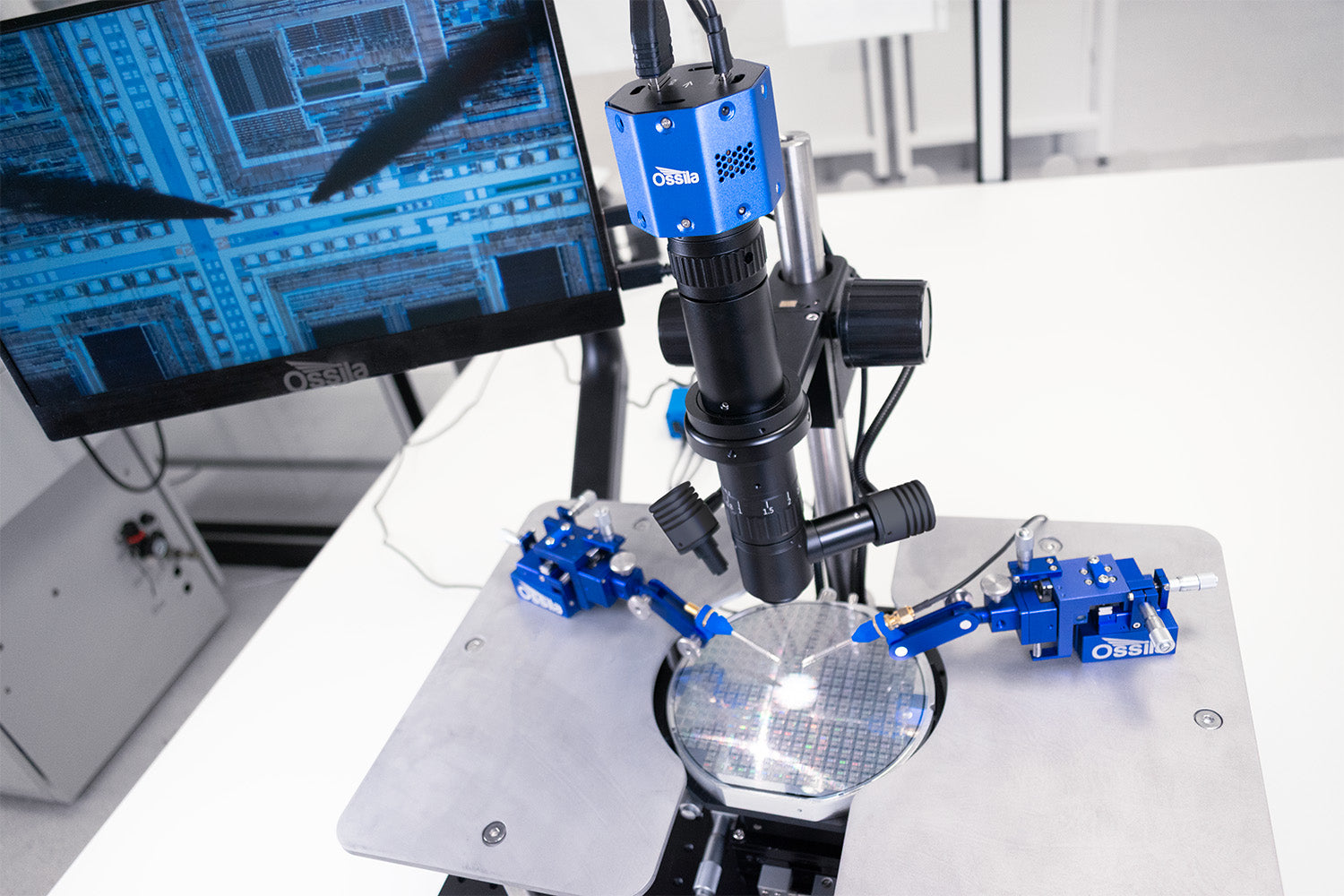

Manual probe stations, such as the Ossila Probe Station, include the following components as standard

- Micromanipulators

- Probe Station Base

- Stereo or Microscope Camera

- Stage or Chuck for your sample

You need each of these components to be high quality, reliable and durable. You will also need to align these components properly, and ensure the system is practical and easy to use. If these criteria are met, this will be more than enough to conduct simple electrical tests or I-V measurements on a wide range of samples. Combine this reliable probe station with our precise source measure unit in the Electrical Characterization System which provides you with everything you need for simple, reliable electrical characterization.

However, certain applications require higher levels of motion control, automation or shielding than manual probe stations can provide. Some questions to consider include:

- Are you doing high voltage, low light, or low-current measurements? If so, you need shielding for your probe station.

- What are the dimensions of your landing pads or sample? This can determine your required positioning resolution and camera magnification.

- Are you testing hundreds of devices at once? Will your research require a lot of data processing? Are your samples delicate requiring controlled probing? If so you may need automated motion control.

- Do you require environmental control? For example, some experiments require thermal control, which requires a heated chuck or a vacuum cryostat.

For some of the above applications, it will be necessary to acquire appropriate shielding, or buy systems with high precision, automated controls.

Automated vs. Manual Motion Control

For automated or programmable probe stations, an external system or software controls the movement of micromanipulators, the sample stage, or both. Automated control systems are great for:

- High precision measurements, or taking lots of measurements over large areas, such as doing advanced wafer level testing on an industrial scale wafer. This will require both extremely precise probe placement and potentially large amounts of data management

- Sensitive probe positioning experiments, such as cell injection. Delicate biological samples will require precise and careful probing. Here, automated movement of micromanipulators is vital to approach carefully.

- Biological measurements carried out over long time periods (days or weeks), automatic control of micromanipulators is needed to counteract thermal expansion, contraction or drift of components to keep the tip of the probe at a fixed point (e.g. near a cell).

- Ease of use. These systems can be more comfortable to use, especially if you are doing long or arduous measurements.

However, this high level of automated motion control often comes with a high cost.

In manual probe stations, the movement of both the stage and probes are controlled by analog mechanisms such as micrometer heads. The main benefits of manual probe stations are their simplicity, versatility and low cost.

The positioning resolution you need will depends on what you are measuring i.e. the size of your landing pads, contacts, or samples. Movement resolution matters most in automated probe stations where probe placement needs to be very precise.

A good rule of thumb is that the probe movement resolution should be at least half of the smallest dimension of your contact pad or probing area For example, if your pad has a 50 x 100 µm area, you will need a system which has 25 µm axes resolution in at least one axes. You will also need a probe tip of less than 25 µm tip diameter.

The Ossila Probe Station stage has 25 mm travel range in the X,Y axes and 10 mm in Z axes with 0.1 mm resolution. Stage movement is used for coarse sample positioning. Ossila Micromanipulators have fine pitch motion resolution of 4-8 µm or 2-4 µm, depending on the model chosen.

Choosing Chucks and Stages For Your Station

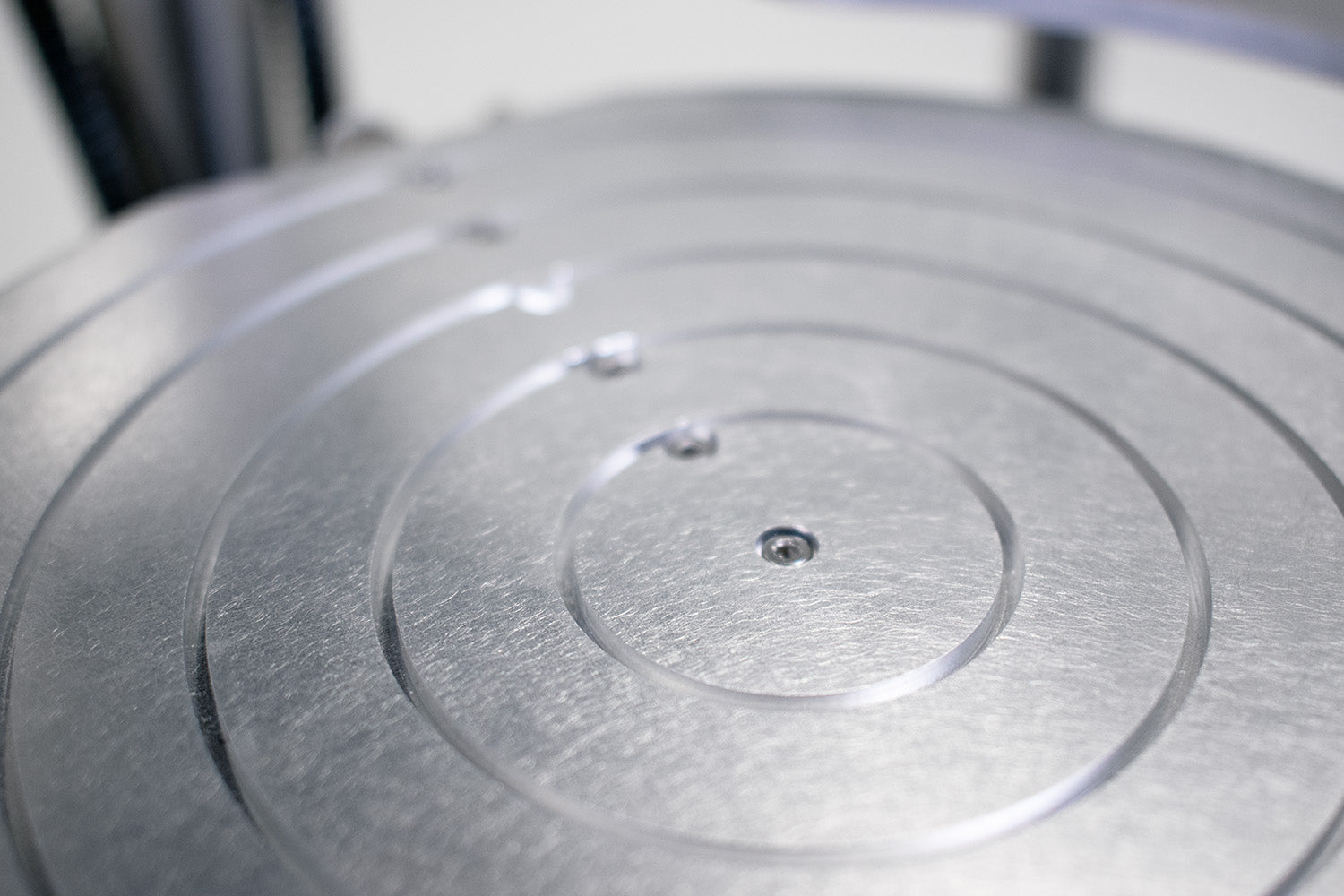

A key consideration for any probe station is the chuck material. Most importantly, these chucks should be conductive, durable and level. Most chucks are made from steel, or sometimes aluminum.

The most common type of probe station chucks are vacuum-compatible. Vacuum chucks can be connected to a vacuum pump, such as the Ossila Diaphragm Vacuum Pump, which holds the sample in place during measurement. These vacuum chucks often have indented rings of varying sizes allowing you to define different vacuum areas. This stage design will determine the size of substrate you can fix in place.

Many probe station chucks are designed to really high specifications, with exceptional flatness, planarity, special connectors, integrated thermal or vacuum systems and rigorously-tested electrical properties. These all contribute to a very high cost. This is great for highly specialized measurements, but most R&D applications do not require this level of specialization.

Some probe stations have stages with high levels of ergonomic control and tactile interfaces. These contribute to a good user experience but also contribute significantly to the total cost of the probe station.

The vacuum compatible chuck included with the Ossila Probe Station is a good compromise of value, practicality and quality: providing a flat surface with multiple vacuum zones and a connection to ground. This vacuum chuck is designed to accommodate samples from 5 - 150 mm diameter, with 6 selectable vacuum zones, giving you maximum flexibility.

In our probe station design, we found in many cases all you need is a simple and clean method for coarse and fine placement of the DUT under a reliable microscope. The Ossila Probe Station stage is a good compromise of value, ergonomics and what is actually needed: just a simple but precise XYZR stage with fine movement control - without the fancy control systems.

Shielding and Enclosures

The immediate environment around a sample can significantly affect electrical measurements. For certain measurements, probe stations can be used with different types of shielding and enclosures to control these environmental influences:

- EMI Shielding: These enclosures (often like a Faraday cage) are very useful for reducing electrical noise from external sources (e.g., radio frequencies, power lines). This is particularly important for sensitive low-current, low-voltage, or high-impedance measurements.

- High Voltage Safety: When testing devices at high voltages, safety enclosures with interlocks are essential to protect operators from electrical hazards.

- Specialized Environmental Chambers: For advanced characterization, the sample environment itself needs control.

- Vacuum Chambers: Allowing tests under vacuum to prevent oxidation, mimic space environments, or specific surface-sensitive measurements.

- Controlled Atmosphere Chambers: Enabling testing in specific gas environments (e.g., inert gases like nitrogen or argon) to protect sensitive materials or study their response.

- Cryogenic Chambers: These are integrated into cryogenic probe stations to cool samples to extremely low temperatures (e.g., down to a few Kelvin) for studying temperature-dependent phenomena like superconductivity or quantum effects.

These control measures ensure measurement integrity, device safety, and operator protection.

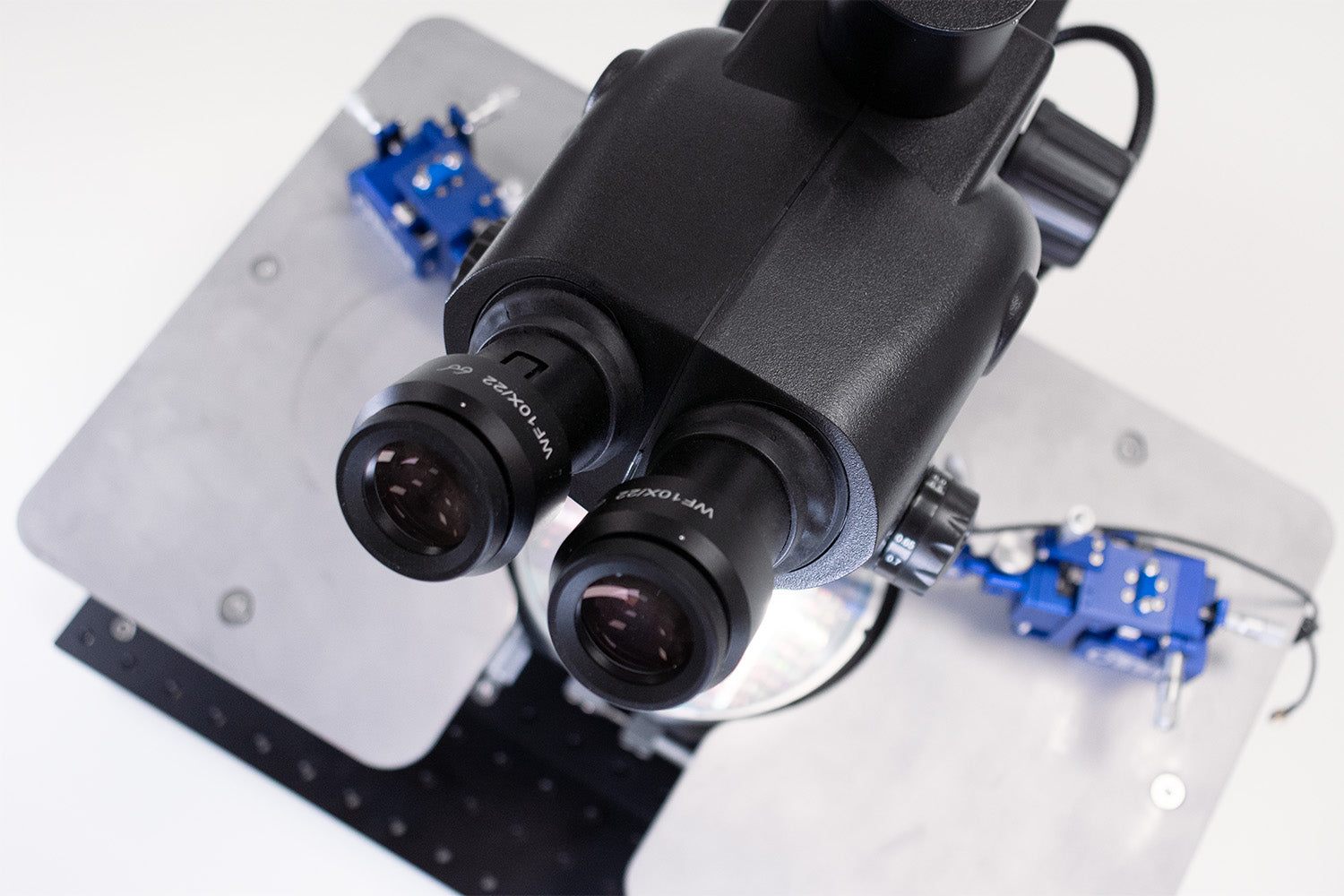

Digital Or Stereo Microscopes

Probe stations come with either a digital or stereo microscope for positioning probes and samples. There are benefits and disadvantages for both of these options, but it often comes down to user preference. Below are some of the pros and cons of both microscopes.

| Stereo Microscopes | |

|---|---|

| Advantages | Disadvantage |

|

|

|

|

|

|

|

|

|

| Digital Microscopes | |

|---|---|

| Advantages | Disadvantage |

|

|

|

|

|

|

|

|

|

The Ossila Microscope Camera shows 4K images, and has a direct HDMI connection to connect to a monitor so there is no lag time. While streaming via HDMI to a monitor, this camera can simultaneously be connected to a PC via USB, giving both instant feedback on the monitor, with the flexibility to save images to the PC.

Vibrational Damping And Physical Stability

In any probe station, it is important to reduce noise and external disturbances as much as possible. Any unwanted motion will risk damaging delicate samples or probe breakages. At the very least, unwanted vibrations will compromise your measurement.

There are two types of vibrational damping: active and passive. Active damping involves systems that act to cancel out any vibrations. These systems can be extremely effective but are also very expensive.

Passive damping mechanisms are methods which mitigate vibrational noise via non-active methods, such as using buffer materials or mechanical links. With proper material selection, passive dampening systems can be extremely effective and much less costly than active systems.

Additionally, micromanipulators are positioned on magnetic platens. Using a magnetic stage reduces any movement or shaking of micromanipulators during use. This will also mean you can't knock micromanipulators out of place during experiments, while still allowing you to intentionally adjust them.

When designing our probe station, we followed appropriate guidelines to select the most appropriate elastomeric dampening feet for our probe station. The Ossila Probe Station vibration dampening feet isolate any frequencies above 17 Hz.

Probe Station

Contributing Authors

Written by

Application Scientist

Product Developer