Single-Walled Carbon Nanotubes

CAS Number 308068-56-6

Anode Materials, Carbon Nanotubes (CNTs), Low Dimensional Materials

Please choose the appropriate MSDS from the list below. Links will open in a new window. If your browser does not support PDFs, you will be prompted to download the file instead.

High quality single-walled carbon nanotubes in dry powder form

SWCNT including SWCNT-OH and SWCNT-COOH functionalised nanotubes exhibits exceptional mechanical, electrical, thermal, and optical properties

|

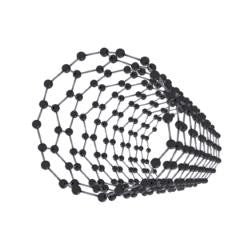

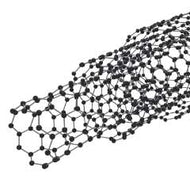

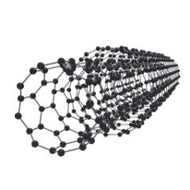

Single-walled carbon nanotubes (SWNTs), CAS number 308068-56-6, are a special class of carbon materials known as one-dimensional materials. They consist of sheets of graphene, rolled up to form hollow tubes with walls one atom thick. Due to its chemical structure and dimensional constraints, this material exhibits exceptional mechanical, electrical, thermal, and optical properties. As such, carbon nanotubes have become of great interest for both stand-alone studies and for use in composite materials. At Ossila, we sell a range of SWNTs with different purities, lengths and wall types. Additionally, we sell carbolic acid (-COOH) and hydroxyl (-OH) functionalised nanotubes. |

||

High Purity

5-35 μm - 95% purity

Worldwide shipping

Quick and reliable shipping

Semiconductor

Semiconducting depending upon the difference between the n and m units

Versatile

exceptional mechanical, electrical, thermal, and optical properties

What are Single-Walled Carbon Nanotubes?

SWNTs are sheets of graphene that have been rolled up to form a long hollow tube, with wall thickness of a single atom. The existence of thin, hollow carbon tubes has been known about since their first observations by L. V. Radushkevich and V. M. Lukyanovich in 1952, however, the first observations of SWNTs themselves were not until 1976 when M. Endo synthesised a series of hollow carbon tubes via chemical vapour-growth. Wider interest in these low-dimensional materials did not occur until 1991, when two articles were independently published by: i) S. Iijima on the fabrication of multi-walled carbon nanotubes via arc discharge, and ii) J. W. Mintire, B. I. Dunlap, and C. T. White on the predicted properties of SWNTs. The combination of a simple method for producing SWNTs and the potentially extraordinary properties they exhibit kick-started the growth of a wider research community into carbon nanotubes.

Much like graphene, SWNTs have properties that differ considerably to those of bulk carbon (e.g. graphite). The mechanical properties vary significantly depending upon the axis you are measuring with nanotubes having extremely high Youngs Moduli (Up to 1TPa) and tensile strength (Up to 100 GPa) along the longitudinal axis. Along the radial axis, these values are a few orders of magnitude lower.

The electrical properties of carbon nanotubes are dependent upon the orientation of the lattice. The lattice orientation is given by two parameters (n, m). The image to the right shows how the n and m orientations relate to the longitudinal axis of the nanotube and the rotational axis. There are typically three types of nanotubes that can form, these are: the armchair (where n = m), zig-zag (n=x, m=0), and chiral (n=x, m=y).

Carbon nanotubes can exhibit either metallic properties or semiconducting properties, depending upon the orientation of the lattice. Zig-zag and armchair carbon nanotubes exhibit metallic properties, whilst chiral nanotubes can be either metallic or semiconducting depending upon the difference between the n and m units. In addition to this ability to exhibit both metallic and semiconducting electronic structures carbon nanotubes offer exceptional charge carrier mobilities, this is due to the combination of the delocalisation of electrons across the lattice and the small dimensions in the radial axis constraining movement of charge carriers along the longitudinal axis of the tubes.

In addition to the electronic and mechanical properties of SWNTs, the thermal properties of these materials exhibit extreme anisotropy. Along the length of the tube, thermal conductivity can be up to 9 times higher than materials such as copper. However - across the radial axis, the thermal conductivity can be 250 times lower than that of copper. Much like its electrical and mechanical properties, SWNT's thermal properties can be severely affected by the presence of defects along the nanotube length. The presence of these defects lead to phonon scattering. When these defects interact with low frequency phonons, scattering can occur - reducing the thermal conductivity.

At the time being, there are limited commercial applications for SWNTs. They are used in composite materials as a method of improving mechanical strength. One of the current limiting factors in improving the range of applications of carbon nanotubes is the ordering of nanotube structure. Current commercial applications utilise disordered bundles of nanotubes, and these bundles have a significantly lower performance than that of individual nanotubes. Potential future uses for carbon nanotubes could be seen in areas such as transparent conducting layers for use in display technologies, conductive wires for nanoelectronics, electrodes in thin-film electronic devices, carbon nanotube yarns for ultra-strong fabrics, thermal management systems, advanced drug delivery systems and many other wide-ranging fields.

Dispersion Guide

SWNTs are insoluble as prepared. However, through the use of surfactants and ultrasonic probes, it is possible to disperse and suspend small concentrations of nanotubes. For dispersing in aqueous solutions, we recommend the use of sodium dodecylbenzene sulfonate if an ionic surfactant is suitable. If a nonionic surfactant is needed, we recommend surfactants with high molecular weights.

- Weigh out the desired amount of carbon nanotubes.

- Mix together your solvent and surfactant of choice at the desired surfactant concentration; this should be below the critical micelle concentration of the surfactant.

- Add the solvent-surfactant mix to the dry powder and shake vigorously to mix.

- Either place an ultrasonic probe into the solution, or place the solution into an ultrasonic bath.

- Be careful about the length of time and power used - because damage to the carbon nanotubes can occur, shortening their average length.

- The resulting solution will be a mixture of suspended SWNT's and bundles of SWNT's, further sonication will help break up the bundles.

- To separate out the individual nanotubes in solution from the bundles, the solution should be placed into a centrifuge. If the solution is centrifuged for a longer time and/or at a higher speed, the smaller bundles will be removed, narrowing the distribution of suspended nanotubes.

For functionalised SWNTs, it is possible to disperse them without the use of any surfactants. However, the total concentration of dispersed nanotubes will be lower. A maximum of 0.1mg/ml can be achieved for -COOH and -OH.

Characterisation

Literature

- Filamentous Growth of Carbon Through Benzene Decomposition, A. Oberlin et. al., J. Cryst. Growth, 32, 335-349 (1976); DOI: 10.1016/0022-0248(76)90115-9

- Helical Microtubules of Graphitic Carbon, S. Iijima, Nature, 354, 56-58 (1991); doi: 10.1038/354056a0

- Are Fullerene Tubules Metallic?, J. W. Mintire et al., Phys. Rev. Lett., 68, 631 (1992); doi: 10.1103/PhysRevLett.68.631

- Large-Scale Production of Single-Walled Carbon Nanotubes by the Electric-Arc Technique, C. Journet et. al., Nature, 338, 756-758, (1997); doi: 10.1038/41972

- Bandgap Fluorescence from Individual Single-Walled Carbon Nanotubes, M. J. O'Connell et. al., Science, 297, 593-596, (2002); doi: 10.1126/science.1072631

-

Atomic Structure and Electronic Properties of Single-Wall Carbon Nanotubes Probed by Scanning Tunnel Electron Microscope at Room Temperature.

A. Hassanien et. al. Appl. Phys. Lett., 73, 3839 (1998); DOI: 10.1063/1.122910 - Solution Properties of Single-Walled Carbon Nanotubes. J. Chen et. al., Science, 282, 95-98, (1998); DOI: 10.1126/science.282.5386.95

- Structure-Assigned Optical Spectra of Single-Walled Carbon Nanotubes. S. M. Bachilo et. al., 298, 2361-2366, (2002); DOI: 10.1126/science.1078727

- Carbon Nanotubes—The Route Towards Applications. R. H. Baughman et. al. Science, 297, 787-792, (2002) DOI: 10.1126/science.1060928

Technical Data

| CAS Number | 308068-56-6 |

| Chemical Formula | CxHy |

| Recommended Dispersants | DI Water, DMF, THF, Ethanol, Acetone |

| Synonyms | Single-Walled Carbon Nanotubes, Single-Wall Carbon Nanotube, Carbon Nanotube, SWNT, CNT |

| Classification / Family | 1D materials, Carbon nanomaterials, Nanomaterials, Polycyclic aromatic hydrocarbons, thin-film electronics |

| Appearance | Black fibrous powder |

All our SWNTs come packed as dry powders, which can be dispersed within the user's solvent of choice.

Single-Walled Carbon Nanotube Powders

| Product code | M2013L1 | M2013L4 | M2013L5 |

| Outer Diameter | < 2 nm | < 2 nm | < 2 nm |

| Length | 4 μm - 20 μm | 5 μm - 35 μm | 20 μm - 55 µm |

| Specific Surface Area | 400 m2g-1 - 1000 m2g-1 | ~ 400 m2g-1 | ~ 570 m2g-1 |

| Purity | > 95% | > 95% | > 96% |

Functionalised Single-Walled Carbon Nanotube Powders

| Product Code | M2014L1 | M2014L2 | M2015L1 | M2015L2 |

| Outer Diameter | < 2 nm | < 2 nm | < 2 nm | < 2 nm |

| Length | 5 μm - 30 μm | 5 μm - 25 μm | 5 μm - 30 μm | 5 μm - 35 μm |

| Specific Surface Area | 380 m2g-1 | 370 m2g-1 | 380 m2g-1 | 370 m2g-1 |

| Functional Group | COOH | COOH | OH | OH |

| Functional Group Wt% | ~ 3% | ~ 2.7% | ~ 4% | ~ 4% |

| Purity | > 90% | > 92% | > 90% | > 92% |

*For larger orders, please contact us to discuss prices.

MSDS Documents

Single-Walled Carbon Nanotube MSDS Sheet

Single-Walled Carbon Nanotube MSDS Sheet

Single-Walled Carbon Nanotube COOH Functionalised MSDS Sheet

Single-Walled Carbon Nanotube COOH Functionalised MSDS Sheet