Diaphragm Vacuum Pump

Equipment Accessories, Large Area Coating, Probe Station, Thin Film CoatingLow-vibration, Oil Free Vacuum Pump for Low-Level Vacuum Applications

Secure substrates, wafers, and laboratory tools quietly and stably with compact, oil-free suction

Overview | Specifications | Applications | In the Box | Compatible Equipment

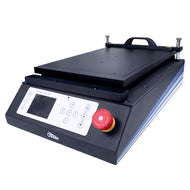

Secure your substrates, wafers, and equipment with the Ossila Diaphragm Vacuum Pump. Designed specifically for vacuum chucks and holding fixtures, this pump provides a consistent suction force (max vacuum -330 mbar) with low noise (<45 dBA), dual stage damping (for low vibration) and a maximum flow rate of 7 L/min.

This system is specifically optimized for low-vacuum uses such as:

- Securing silicon wafers on the Ossila Probe Station

- Holding a flexible substrate flat and securely on the Ossila Automatic Film Applicator

- Powering vacuum-base micromanipulators.

The Ossila Diaphragm Vacuum Pump offers a convenient, plug-and-play connection to Ossila equipment (through 6 mm push-fit connection). The in-built analog gauge allows you to instantly assess the vacuum state, troubleshoot and identify leaks.

Unlike large industrial pumps, this system is oil-free requiring minimal maintenance with no oil-contamination risk. With a small footprint, an integrated pressure gauge, and simple push-fit connectivity, it fits seamlessly into any crowded glove box or lab bench setup.

Dual Vibration Isolation

Internal spring suspension and external damping feet

Quiet operation

<45 dBA noise level for comfortable use in open labs

Oil Free System

Low maintenance compared to rotary vane pumps

Integrated Gauge

Dual-scale dial (mbar/mmHg) for clear, instant readings

Specifications

| Pump Type | Diaphragm (oil-free) |

|---|---|

| Maximum Flow | 7 L/min |

| Max. Vacuum (gauge) | -680 mbar (-510 mmHg) |

| Max. Vacuum (abs) | 330 mbar |

| Motor Type | DC Brushless |

| Max. Power | 4 W |

| Pump Head Material | PPS |

| Diaphragm Material | EPDM |

| Valve Material | EPDM |

| Rated Pump Lifetime | 6000 hours |

| Power Requirement | 24 VDC |

| Gauge Units | mBar & mmHg |

| Tubing Connector | 6 mm Push-fit |

| Noise | <45 dBA at 1 m |

| Vibration | Low (dual-stage damped) |

| Weight | 1 kg |

| Dimensions (L x W x H) | 15 x 12 x 14 cm |

| Ventilation | Internal Ventilation (Clean gas only, no liquids/gases that need to be recovered) |

Dual-stage vibration isolation

Standard laboratory pumps often generate significant mechanical noise. To combat this, the Ossila Vacuum Pump features a dual-stage isolation architecture designed to decouple the pump mechanism from your laboratory environment:

- Internal suspension: The core pump module is suspended on a four-point horizontal spring mount. This floating design effectively absorbs vibration in all three axes (X, Y, and Z), preventing internal motor oscillations from transferring to the outer chassis.

- External damping: The metal chassis sits on high-grip, shock-absorbing rubber feet, providing a secondary layer of isolation between the unit and your optical table or workbench.

This makes our vacuum pump perfect for integration with probe stations and other for laboratory applications where mechanical stability is critical. This multi-axis reduction ensures that your probe tips remain steady and your coating substrates remain undisturbed, even when the pump is operating at full capacity.

Applications

This pump is versatile and suitable for a wide range of laboratory “hold-down” and handling tasks:

-

Probe Station Vacuum Chucks. Designed as the ideal companion for the Ossila Probe Station, this pump ensures your devices remain stationary during characterization. It provides sufficient force to lock the sample to the chuck, ensuring stable electrical contact during probing without introducing vibrations that could dislodge needle tips.

-

Film Applicator & Coating Beds. Ideal for use with the Ossila Automatic Film Applicators (and similar doctor-blading or slot-die coating systems). It ensures flexible or rigid substrates remain perfectly flat against the porous vacuum bed, resulting in uniform film thickness and preventing substrate movement.

-

Vacuum Tool Holding. Perfect for securing vacuum-base manipulators and optical mounts to optical tables or probe stations.

-

Pick-and-Place Systems. Can be utilized as the vacuum source for manual or automated vacuum tweezers, allowing for the damage-free handling of delicate solar cells, OLEDs, or glass coverslips.

In the Box

- Diaphragm Vacuum Pump

Compatible Equipment