Hole Injection Layer Materials

Hole Injection Layer (HIL) Materials are essential for reducing the energy barrier between the anode and adjacent layers, enabling efficient charge transport in electronic devices. By minimizing this barrier, HIL materials lower the required operating voltage, enhancing device efficiency.

HIL materials are particularly important in organic light-emitting diodes (OLEDs), where the electron affinity of the materials is typically lower than in other organic electronic devices. Their role is crucial in facilitating effective hole injection, which is a key factor in achieving high-performance electronic devices.

The key features of hole injection layer materials are:

HIL materials like HATCN can impart increased external quantum efficiency, current efficiency and power efficiency on OLED devices, compared to tradition PEDOT:PSS based devices. Many HIL materials provide interfacial modifications to reduce the work function of the anode and improve interlayer interactions.

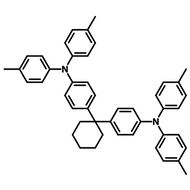

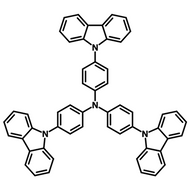

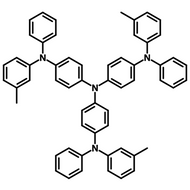

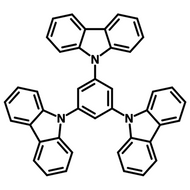

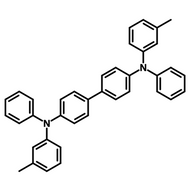

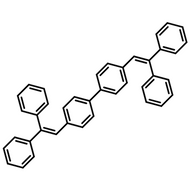

Explore our range of hole injection layer materials, such as TCNQ and 2-TNATA, to significantly reduce the barriers to hole transport in your OLED devices.

Browse Hole Injection Layer Materials

Related categories: OLED materials, Charge Transport layer materials, Dopant materials, Host materials, TADF materials

Filter by purification technique: