Slot Die Coating

Set Up Your System | Define your Coatings | How to Customize Your System | Resources and Support | Technical Support

Slot Die Coater

Elevate your research with low cost, scalable coating technology.

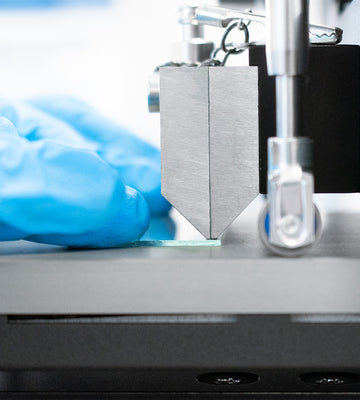

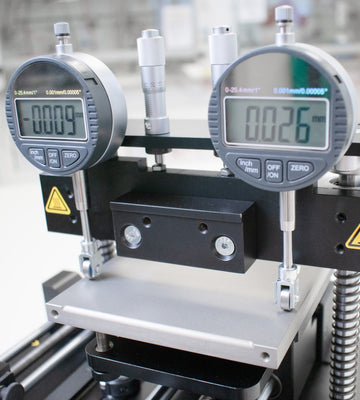

Our complete slot die coater features an integrated high-precision syringe pump and customizable head. With stage speeds ranging from 50 μm.s-1 to 75 mm.s-1, an improved flow rate range (0.5–624 μl.s-1 for a 5 ml syringe), easy leveling, and large coating area, you have full control over the parameters critical to improving the uniformity of your films.

This slot die coater is suitable for users at any level. With intuitive software and adaptable design, you control the flow rate, coating speed, plate temperature, alignment, channel thickness, head height, multiple step programming, and more.

Set Up Your Slot Die Coater

Prepare your research for scale-up with our slot die coating range. Designed for flexibility and precision, the Ossila Slot Die Coater gives you complete control over coating parameters through intuitive software and a wide selection of useful accessories to customize your set up. Achieve consistent, high-quality films every time.

Define Your Coatings

Customize Your Slot Die Coating Process

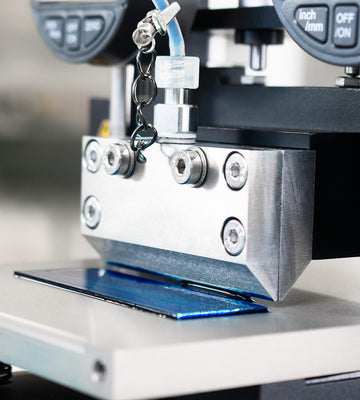

One of the key advantages of slot die coating is the straightforward relationship between wet-film thickness, solution flow rate, and substrate speed. With our range of accessories, you can fine-tune these parameters to achieve greater precision, flexibility, and repeatability in your thin-film coatings. With interchangable add-ons and accessories, you can further tailor your slot die coater to fit your coating needs.

Solution Deposition Control

You can control solution deposition in slot die coating by using shims and meniscus guides between the slot die head pieces. Shims define the channel width which helps control pressure drop across the slot die head. Meniscus guides pin and guide the solution pathway, preventing unwanted spreading. We would recommend using both of these for optimial slot die coating.

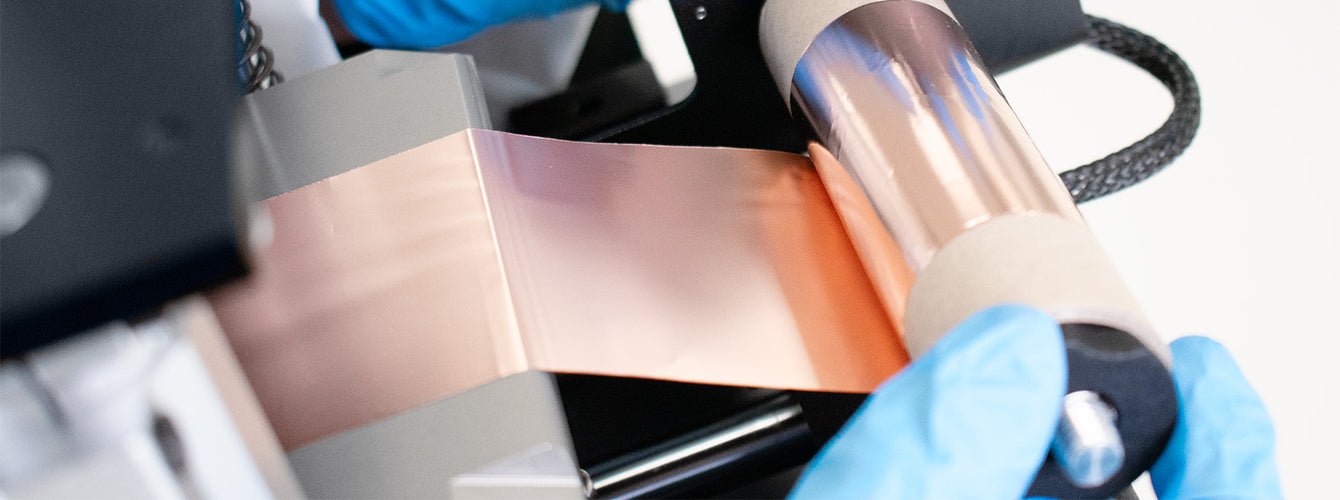

Flexible Substrate Coating

Move your slot die coating beyond rigid substrates and optimize coatings on flexible substrates with the roll attachment. This allows you to optimize coating of foils, PET films and other flexible substrates with small amounts of solution, while ensuring your methods remain compatible with larger, industrial roll-to-roll systems.

Drying Management and Post-Deposition Treatment

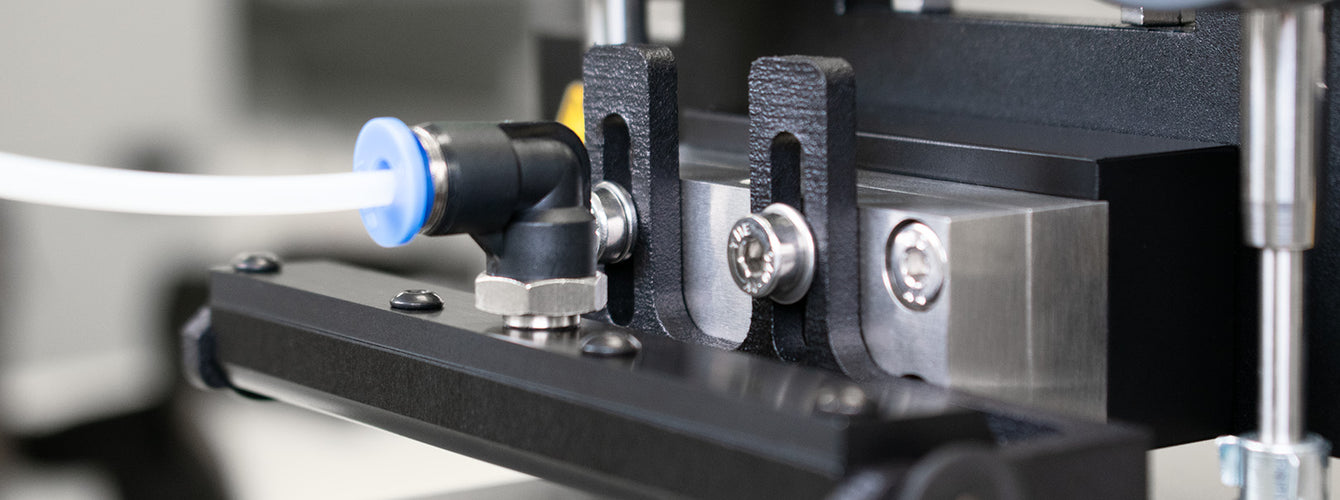

Control drying mechanisms post-coating with the air knife for slot die coaters. An air knife creates a controlled curtain of air that can be directed towards your wet film at a variety of angles. Moving in sync with the coating head, it allows you to adjust both angle and distance for precise control of the drying front.

Expanding Functionality

Beyond slot die coating, you can also experiment with alternative coating methods such as bar coating with the bar coater adapter. This allows you to mount Mayer bars onto your slot die coating for coating small substrates and take advantage of optimized drying with the the heated stage and air knife attachments.

Optimize Solution for Slot Die Coating

With the bar coating adaptor, you can also start optimizing your solution for large scale coating before fine-tuning slot die coating parameters. Bar coating is a relatively simple technique that can easily make a thin film. You can initally use the bar coating adaptor to make sure your solution will spread nicely, and to find an optimum coating speed or optimal film thickness. Once you have done this, you can begin optimizing the slot die coating process with a few key parameters already figured out.

Resources and Support

How to Set Up the Ossila Slot Die Coater

How to Set Up the Ossila Slot Die Coater

Learn how to set up your slot die coater and how to define your coating paramters in order to effectively optimize your coating processes.

Read more... How to Attach the Slot Die Coater Roll Attachment

How to Attach the Slot Die Coater Roll Attachment

Learn how to setup the roll attachment to easily coat foils and other flexible substrates without the need for a vacuum stage.

Read more...Slot die coating is an extremely versatile deposition technique in which a solution is delivered onto a substrate via a narrow slot positioned close to the surface.

Read more...When it comes to depositing highly-uniform wet thin films, there are many different solution-processing techniques capable of producing high-quality films at low cost.

Read more...Technical Support