Solvent-Safe Chucks for Vacuum-Free Spin Coating

Spin coater chucks to accommodate popular substrate sizes

Overview | Specifications | Gallery | Resources and Support

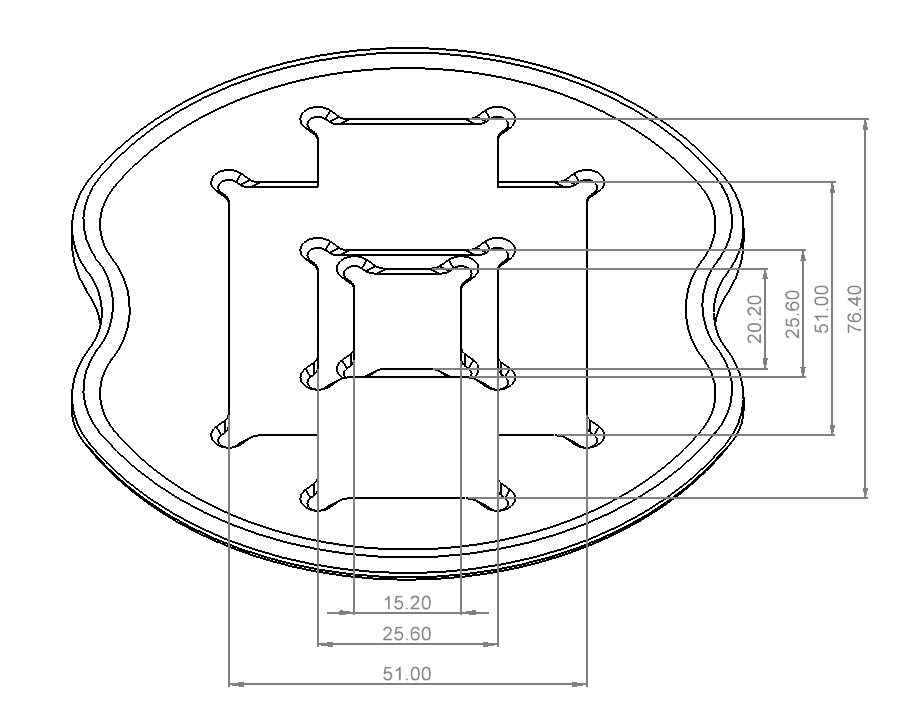

We stock a range of vacuum-free spin coater chucks compatible with the Ossila Spin Coater. The interchangeable chucks have a push-fit base that fits firmly and securely onto the spin coater coupling. All of our chucks have a recess which holds the substrate securely in place while allowing excess solution to drain away.

Our multi-substrate chucks use our new rimmed edge design to help improve air flow uniformity within the spin bowl and to reduce solvent build up within the bowl. With improved and simplified drainage channels, this chuck reduces buffeting during spin coating and improves the stability of the chuck during spinning. In addition, finger cutouts allow for the easy removal of chucks allowing you to change them for different experiments.

We can produce custom chucks to fit your substrates. Simply contact us with your requirements and we can determine the right chuck for you. Specify three dimensions (length, width, and depth) when ordering a custom chuck.

Specifications

Multi-substrate Chuck

| Product Code | L2001-U1 | L2001-U2 | L2001-U3 |

|---|---|---|---|

| Compatible Substrate Sizes | 20mm x 15mm, 25mm x 25mm (1" x 1"), 50mm x 50mm (2" x 2"), and 75mm x 25mm (3" x 1" / microscope slides) | ||

| Material | Polypropylene | PTFE | PEEK |

Custom Chucks

Custom chucks are available at a discounted price with the purchase of a spin coater, but can also be purchased separately. Please contact us to discuss your needs, specifying the length, width, and height of each substrate. Alternatively, STL, STEP, and SLDPRT files (for AutoCAD / FreeCAD and SolidWorks respectively) are freely available to download should you wish to create your own chucks.

Custom Chuck Requirements

| Maximum diameter of chuck | 115 mm |

|---|---|

| Maximum diameter of substrate | 100 mm (4") |

Blank Chuck Downloads

Version 2

Version 1

- .STL file for AutoCAD and TurboCAD

- .SLDPRT file for SolidWorks

Spin Coater Chuck Gallery

Resources and Support

Reinventing the Spin Coater Chuck

Reinventing the Spin Coater Chuck

The bigger, better chuck provides an all-in-one solution if you have multiple sizes of substrates to coat. Plus improved aerodynamics and mechanical performance produce more uniform films.

Read more... How to Change Ossila Spin Coater Chucks

How to Change Ossila Spin Coater Chucks

Our spin coater chucks are equipped with a push-fit connection to the motor coupling within the spin coater. This makes cleaning or changing the chuck simple.

Read more...