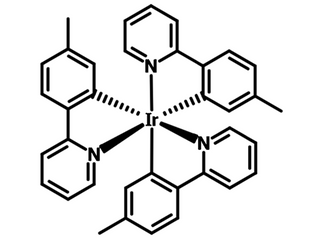

Ir(mppy)3

CAS Number 149005-33-4

Dopant Materials, Green Dopant Materials, High Purity Sublimed Materials, Materials, OLED Materials, Semiconducting MoleculesIr(mppy)3, green light emitting phosphorescent dopant

Used in highly efficient OLED and TADF-OLED devices, Tris[2-(p-tolyl)pyridine]iridium(III), CAS No. 149005-33-4, Sublimed ≥99.0%

Ir(mppy)3, Tris[2-(p-tolyl)pyridine]iridium(III), is widely used as a phosphorescent dopant which emits green light in highly efficient OLED and TADF-OLED devices. With three methyl groups attached to the ppy ligands, Ir(mppy)3 is more soluble than the widely known green emitter Ir(ppy)3.

When it is co-doped with Ir(ppz)3, Ir(mppy)3 devices show a slower efficiency roll-off and higher electroluminescent efficiencies due to improved recombination probability and suppressed exciton quenching.

General Information

| CAS number | 149005-33-4 |

|---|---|

| Full name | Tris[2-(p-tolyl)pyridine]iridium(III) |

| Chemical formula | C36H30IrN3 |

| Molecular weight | 696.86 g/mol |

| Absorption | λmax 375 nm in DCM |

| Fluorescence | λmax 515 nm in DCM |

| HOMO/LUMO | HOMO = 5.6 eV, LUMO = 3.0 eV [1] |

| Synonyms | Tris[2-(p-tolyl)pyridinium-1-yl] iridium(III) |

| Classification / Family | Iridium complexes, Phosphorescent dopant materials, Phosphorescent green emitter, sublimed materials, Organic electronics. |

Product Details

| Purity | Sublimed >99% (HPLC) |

|---|---|

| Melting point | > 320 °C (0.5% weight loss) |

| Appearance | Yellow powder/crystals |

Chemical Structure

Device Structure(s)

| Device structure | ITO/HAT-CN(10 nm)/HAT-CN:TAPc(2:1, 60 nm)/TAPc(20 nm)/TcTa:Be(pp)2:Ir(mppy)3 (1:1:8 wt% 10 nm)/Be(pp)2:Liq (1:10%, 35 nm)/Liq(1 nm)/Al(1 nm)/HAT-CN(20 nm)/HAT-CN:TAPC(2:1, 10 nm)/TAPC(40 nm)/ TcTa:Be(pp)2:Ir(mppy)3 (1:1:8 wt% 10 nm)/Be(pp)2(15 nm)/Be(pp)2:Liq (1:10%, 35 nm)/Liq(1 nm)/Al(100 nm) [1] |

|---|---|

| Color | Green |

| Max. Current Efficiency | 241 cd/A |

| Max. Power Efficiency | 143 lm W−1 |

| Device structure | ITO (150 nm)/HAT-CN (4 nm)/VB-FNPD* (35 nm)/TCTA:Ir(mppy)3 10 wt% (20 nm)/TPBi (60 nm)/ CsF (1 nm)/Al (120 nm) [2] |

|---|---|

| Color | Green |

| Max. EQE | 14.7% |

| Max. Current Efficiency | 50.9 cd/A |

| Max. Power Efficiency | 55.0 lm W−1 |

| Device structure | ITO/PEDOT:PSS (50 nm)/TCTA (30 nm)/26DCzPPy:Ir(mppy)3 94:6 (40 nm)/TPBI (40 nm)/LiF (0.8 nm)/Al (100 nm) [3] |

|---|---|

| Color | Green |

| Current Efficiency @ 1000 cd/m2 | 41.9 cd/A |

| Power Efficiency @ 1000 cd/m2 | 23.4 lm W−1 |

| Device structure | ITO/PEDOT:PSS/ PVK :OXD-7:Ir(mppy)3 (60:40:4, w/w)/TrOH*/Al [4] |

|---|---|

| Color | Green |

| Max. Luminance | 18,050 cd/m2 |

| Max. EQE | 6.7% |

| Max. Current Efficiency | 23.4 cd/A |

| Device structure | ITO/Clevios HIL 1.5 (30 nm)/a-NPD (20 nm)/HTEB-2 (10 nm)/1 wt% Ir(mppy)3:PIC-TRZ (25 nm)/TPBi (35 nm)/LiF (0.8 nm)/Al (100 nm) [5] |

|---|---|

| Color | Green |

| Max. EQE | 20.3% |

| Max. Current Efficiency | 74 cd/A |

*For chemical structure information, please refer to the cited references

Pricing

| Grade | Order Code | Quantity | Price |

|---|---|---|---|

| Sublimed (>99% purity) | M2195A1 | 100 mg | £240 |

| Sublimed (>99% purity) | M2195A1 | 250 mg | £480 |

| Sublimed (>99% purity) | M2195A1 | 500 mg | £800 |

| Sublimed (>99% purity) | M2195A1 | 1 g | £1300 |

MSDS Documentation

Literature and Reviews

- Highly efficient and stable tandem organic light-emitting devices based on HAT-CN/HAT-CN:TAPC/TAPC as a charge generation layer, Y. Dai et al., J. Mater. Chem. C, 3, 6809-6814 (2015);DOI: 10.1039/C4TC02875A.

- High-Performance Hybrid Buffer Layer Using 1,4,5,8,9,11-Hexaazatriphenylenehexacarbonitrile/Molybdenum Oxide in Inverted Top-Emitting Organic Light-Emitting Diodes, C-H. Park et al., ACS Appl. Mater. Interfaces, 7 (11), 6047–6053 (2015); DOI: 10.1021/am5091066.

- Interface and thickness tuning for blade coated small-molecule organic light-emitting diodes with high power efficiency, Y-F. Chang et al., Appl. Phys. Lett.,114, 123101 (2013); doi: 10.1063/1.4821881.