Evaporation Stack for OFETs, Low Density

Low Density Evaporation Stack for OFETs

Enabling accurate deposition resolution

Overview | Specifications | Resources

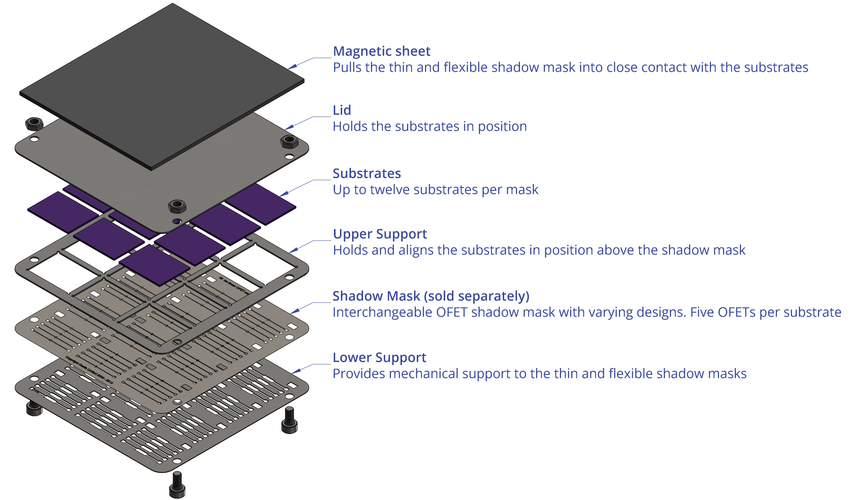

The evaporation stack holds the OFET source-drain shadow masks (sold separately) and substrates in close contact for thermal evaporation. This is crucial for effective device fabrication as the source-drain channel is usually the most critical feature on an OFET. For use with the Ossila low density OFET source-drain evaporation masks and Silicon Oxide Substrates.

Specifications

| Size | 75 mm x 75 mm (2.95" x 2.95") |

|---|---|

| Thickness | 1 mm (exc. bolts) |

| Material | Stainless steel |

| Capacity | 12 substrates |

System Overview

The low density fabrication system has four different masks available (source-drain, gate deposition, active area deposition and insulator deposition) to allow the fabrication of devices in any geometry (top/bottom gates and top/bottom source-drain). The diagrams below show the features on each of the individual masks as well as how they fit together on a substrate.

Note that silicon oxide substrates do not need a gate mask which simplifies fabrication, however the use of a gate mask with quartz-glass substrates can allow lower operating voltages and lower parasitic capacitance.