Rotating Disk Electrode (RDE)

Rotating Disk Electrode (RDE), Pine Compatible

For precise studies of reaction mechanisms, catalyst properties, and kinetic studies of reacting species

Overview | Specifications | Pricing and Options

A rotating disk electrode (RDE) is a disk electrode that spins in electrochemical reactions for the study of electrode kinetics and the mechanisms of electrode processes. With a spinning disk at the bottom end of the electrode, it creates controlled fluid flow with a steady-state current and diffusion layers. Rotating the electrode at a controlled rate creates a consistent, laminar flow of the electrolyte towards the electrode surface, establishing a specific concentration gradient within the diffusion layers. The concentration gradient is a critical factor in determining the mass transport limited current.

As the working electrode in an electrochemical setup, the rotating disk electrode is a classic hydrodynamic electrochemical technique based on controlled convective mass transport by well-defined electrolyte flow. The flow of electrolyte is primarily affected by the rotation rate of the RDE and physical properties of the electrolyte solution itself. RDE enables precise studies of reaction mechanisms, catalyst properties, kinetic studies of reaction rates and diffusion coefficient of reacting species. RDE has also been engaged in the evaluation of catalyst performance, especially for reactions like the oxygen reduction reaction (ORR).

Specifications

All dimensions are in millimeters.

| Disk Material | Glassy Carbon (GC) |

|---|---|

| Body Material | PTFE |

Pricing and Options

| Product Name | Product Code | Price |

| Rotating Disk Electrode, Glassy Carbon, External thread, Pine compatible | C2039C1 | £690 |

Literature and Reviews

- S. Martens et al. (2018), A comparison of rotating disc electrode, floating electrode technique and membrane electrode assembly measurements for catalyst testing, J. Power Sources, 392, 274-284; DOI: 10.1016/j.jpowsour.2018.04.084.

- M. Tesch et al. (2023), The rotating disc electrode: measurement protocols and reproducibility in the evaluation of catalysts for the oxygen evolution reaction, Energy Adv., 2023, 2, 1823-1830; DOI: 10.1039/D3YA00340J.

- Y. Gao et al. (2023), Origin of High Activity and Durability of Confined Ordered Intermetallic PtCo Catalysts for the Oxygen Reduction Reaction in Rotating Disk Electrode and Fuel Cell Operating Conditions, ACS Catal., 13 (16), 10988–11000; DOI: 10.1021/acscatal.3c01926.

Learn More

PEEK vs PTFE

PEEK vs PTFE

The choice of whether to use PEEK (polyether ether ketone) or PTFE (polytetrafluoroethylene, Teflon) comes down to the conditions of your planned experiments. The key polymer properties to consider are:

Read more... What is a Photoelectrochemical Cell?

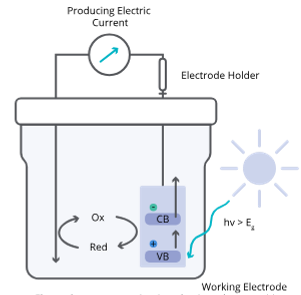

What is a Photoelectrochemical Cell?

A photoelectrochemical cell (PEC) is a device that converts solar energy (light) into chemical energy or electricity. Light activates a semiconductor or photosensitizer component within the cell.

Read more...