Bar Coater vs. Doctor Blade Coater: What's The Difference?

Bar coating and blade coating are two solution-based techniques for depositing thin films. They are able to coat larger areas than spin coating, and they require less optimization than processes like slot-die coating. Although there are many similarities between these techniques, there are some distinctions between them.

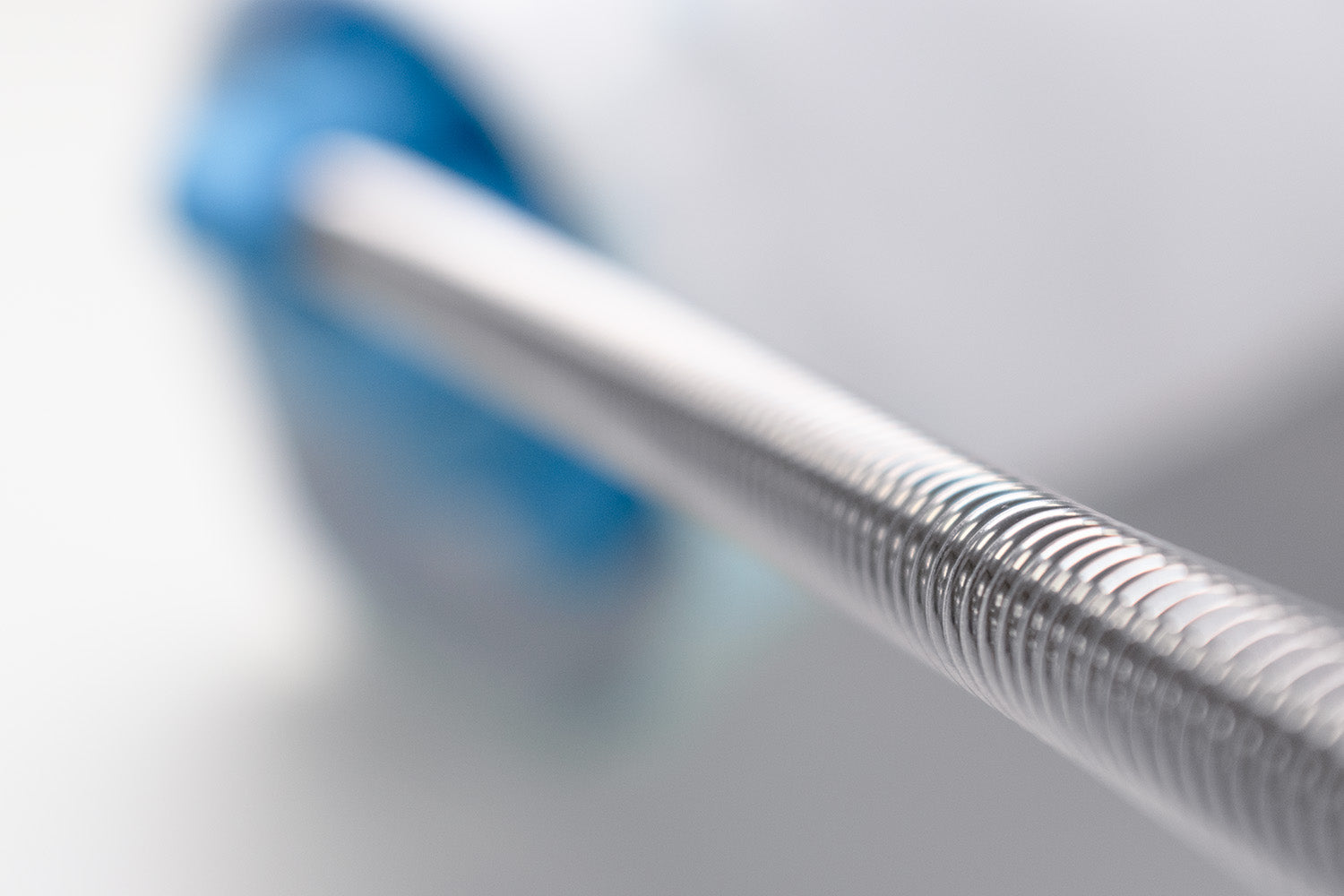

The biggest difference between bar and blade coating is the applicator used to spread the solution. Bar coating uses a spiral rod to spread solution across a substrate, and blade coating uses an adjustable blade. These different applicators can be combined with an automatic thin film applicator to make an automated bar coater machine or doctor blade coater system.

Both methods share similarities in terms of functionality, scalability, and application. For this reason both bar coating and blade coating are used in industries ranging from electronics and energy to automotive packaging.

Bar coating vs. Doctor Blade Coating

Bar coating uses a cylindrical bar, also known as Mayer rod to create a thin liquid film. The Mayer rods can be either wire-wound or formed. The gaps between the wires along determine how much solution is deposited, thereby controlling the film thickness. With a Mayer rod, you can produce films of the same wet film thickness easily and consistently.

Alternatively, blade coating, or doctor blade coating, is another wet coating technique, which creates uniform films by dragging a flat blade across a substrate. The coating gap is largely determined by changing the blade height. By optimizing blade height, angle, speed and solution viscosity, this method offer more precise control over film thickness.

Both techniques can be performed manually or with automated systems like the Ossila Automatic Film Applicator. The easy use and cost-effectiveness make both coating methods popular in applications such as lithium-ion batteries and organic photovoltaics (OPVs).

Some advantages of bar coating involve minimal setup requirement and straightforward operation, which makes it ideal for educational environments. Additionally, Mayer bars provide more consistent force across the substrate, so this technique may be more suitable for coating delicate substrates.

On the other hand in blade coating, researchers are able to adjust the coating gap to achieve optimal film properties. Unlike bar coating—where each Mayer rod produces only a fixed thickness—blade coating offers greater flexibility to fine-tune layer thickness as needed.

Another benefit of blade coating method is the low material waste. With applicators like the adjustable film applicator, the solution is contained in a reservoir while coating, helping to maintain better control of coating width and reduce run off.

Both techniques can coat over large surface areas and are both scalable techniques. On top of that, both work well with both flexible and rigid materials. While these methods offer a wide range of benefits, it is important to keep in mind that its minimum of film thickness is usually around 10 microns. This makes these methods unsuitable for applications that require ultra-thin layers.

Additionally, it is important to keep in mind that the technique has some disadvantages, such as lower preciseness than spin or slot-die coating.

Quick Comparison

| Bar coater | Blade coater | |

|---|---|---|

| Control over film thickness | Limited - depends on the diameter of the rod; change Mayer bar to change thickness | Excellent, especially with adjustable blade height |

| Ease of optimization | Requires switching bars for different thickness | Easier due to adjustable parameters (blade height, speed) |

| Coating uniformity | Good, round bars provide uniform distribution, but surface tension can lead to edge beading | Good, especially with flat blades |

| Cleanliness | Can be messier, especially with low-viscosity inks | Cleaner process, less run-off |

| Manual vs automatic operation | Slightly better for manual use; more forgiving | Better with automated use |

| Reproducibility | High, if bars are cleaned properly and technique is consistent | Depends on operator and equipment precision |

| Cost and scalability | Low cost, easily scalable | Low cost, easily scalable |

| Ink compatibility | Not suitable for particularly high or low viscosity | Not suitable for particularly high or low viscosity |

| Best for | Repetitive, slow coating processes | R&D and multilayer optimization |

| Surface tension impact | Significant | Less dominant |

Choosing the right method

Both of these methods are suitable for thin film coating over large areas. Both are easy to use and simple to optimize. However, there may be some situations where you might choose bar coating over blade coating or vice versa.

| If your goal is... | Go with... |

|---|---|

| Precise control and tunability | Blade coater |

| Quick, repeatable application | Bar coater |

| Optimizing film thickness on-the-fly | Blade coater |

| Budget-friendly, simple setup | Bar coater |

| Scaling up to industrial coating | Bar coater |

| Higher viscosity control | Blade coater |

Use bar coating when:

- Coating needs to be fast and repeatable

- Suitable Mayer rods are available for your solution

- Easy training or manual use is a priority

- Coating very delicate substrates

Use blade coating when:

- Precision and repeatability are critical

- You need to tune multiple parameters

- Conducting material screening or multilayer coatings

- Coating on rigid substrates in academic or R&D settings

Ossila Bar Coater vs. Ossila Doctor Blade Coater

The Ossila Automatic Film Applicator can be set up as a bar coater or a doctor blade coater by changing the type of applicator used. The bar coater kit comes with a full set of 16 Mayer rods for coating a range of wet film thicknesses from 6 μm to 200 μm. These can be easily fixed into the film applicator.

The doctor blade coater kit comes with an adjustable film applicator. This adjustable film applicator is made of stainless steel and comes with digital micrometer gauges. This allows for precise coating gap thickness compared to the analog gauges. With this kit, you can simply place the adjustable film applicator in front of the coating arm, use the micrometer gauges to define your coating thickness and fill the reservoir with your coating solution.

Learn More

Doctor Blade Coating: Method, Coating Thickness and Design

Doctor Blade Coating: Method, Coating Thickness and Design

Doctor blade coating (also known as blade coating) is a common technique used to apply a thin, uniform layer of solution onto a substrate. The process involves using a blade to spread a coating of solution across a surface. The method is widely used across various industries including to coat paper and packaging, textiles, electronics and medical devices. It is a simple, versatile and easy-to-use technique that can produce thin, consistent coatings. This is essential for high-quality finishes for a range of products.

Read more... Bar Coating: Methods, Theory and Applications

Bar Coating: Methods, Theory and Applications

Bar coating is a simple wet processing technique used to deposit a thin layer of solution onto a substrate. It involves a bar being placed above a substrate and dragged over a pool of fluid, resulting in the fluid being spread into a thin film or coating. Bar coating is commonly used in the development of applications such as automotive paints, photovoltaic cells and lithium ion batteries.

Read more...Contributing Authors

Written by

Scientific Writer

Edited by

Application Scientist (Physics)