What is the Difference Between SWCNT and MWCNT?

Single-walled carbon nanotubes (SWCNTs) and multi-walled carbon nanotubes (MWCNTs) have some similarities and some key differences. Both materials are made from hexagonal lattices of carbon, specifically graphene sheets rolled up to form tubular structures. However, the nested structure of MWCNTs gives them distinct properties that differentiate them from SWCNTs.

The table below compares SWCNT vs MWCNT for a variety of features:

| SWCNT | MWCNT | |

|---|---|---|

|

|

|

|

Appearance |

Single layer of graphene |

Multiple concentric layers of graphene |

| Diameter | < 2 nm | > 2 nm |

|

Synthesis Conditions |

Bulk synthesis is difficult Catalyst required |

Bulk synthesis is easy Can be produced without catalyst |

| Electrical Conductivity | 106 S m−1 | 105 S m−1 |

|

Purity |

Poor |

High |

|

Defects |

Higher chance of defects during functionalization |

Lower chance of defects Difficult to repair defects |

|

Retention in body |

Less accumulation |

More accumulation |

|

Characterization |

Easy |

Complex |

|

Flexibility (Young's Modulus) |

High (~ 1 TPa ) |

Poor (1.28 TPa ) |

| Applications |

Electronics and Semiconductors Sensors Transparent Electrodes Optoelectronics Biomedicine: Drug Delivery, Biosensors, Bio-imaging |

Structural Composites Electrochemical Devices Conductive Materials Catalyst Support Water Purification and Filtration |

| Cost and Scalability |

More expensive due to need for precise synthesis conditions |

Cheaper Easier to produce large quantities |

SWCNT vs MWCNT

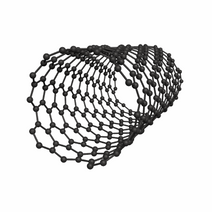

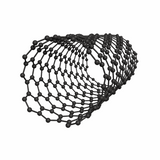

Single-walled carbon nanotubes have just one layer of graphene rolled up into a tube with nanoscale diameters of < 2 nm. This ultrathin 1D structure with a high aspect ratio shows good flexibility and is easy to characterize. SWCNTs can have extremely high electrical and thermal conductivity depending on chirality.

It is this need for control over chirality to access excellent conductivity that makes SWCNT production complicated and expensive. Batches of SWCNTs can often be less pure, with mixtures of chirality. The ultrathin nature also means there is a higher chance of defects during functionalization or treatments. For these reasons SWCNTs are more suited to applications like flexible electronics, sensors, and biomedical applications where their flexibility and nanoscale dimensions can be most exploited.

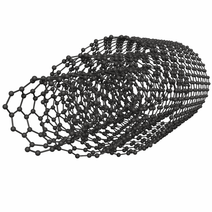

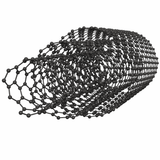

Multi-walled carbon nanotubes are made from nanotubes nestled within one another. These extra layers provide protection against compression as well as defect formation. Due to their lack of flexibility, MWCNTs are best suited to increasing the mechanical strength of a system. They are much cheaper and easier to synthesize on a large-scale. Characterizing MWCNT is much more complicated however.

Single-Walled Carbon Nanotubes (SWCNT)

Learn More

What are Multi-Walled Carbon Nanotubes?

What are Multi-Walled Carbon Nanotubes?

Multi-walled carbon nanotubes (MWCNTs) consist of multiple carbon nanotubes nested within one another. The carbon nanotubes are just one atom thick and this gives MWCNTs unique electrical and mechanical properties.

Read more... What are Single-Walled Carbon Nanotubes (SWCNT)?

What are Single-Walled Carbon Nanotubes (SWCNT)?

Single-walled carbon nanotubes (SWCNTs) are sheets of graphene that have been rolled up to form a long hollow tube, with wall thickness of a single atom. Their one-dimensional structure gives them extraordinary mechanical, electrical and thermal properties.

Learn more...References

- Carbon nanotubes: properties, synthesis, purification, and medical applications, Eatemadi, A. et al., Nanomaterials (Basel) (2014)

- Carbon Nanotubes in Agriculture: Production, Potential, and Prospects, Rudaklya, D. et al., Nanomaterials (Basel) (2019)

- Single-Walled vs. Multi-Walled Carbon Nanotubes: Influence of Physico-Chemical..., Solorio-Rodriguez, S. A. et al., Nanomaterials (Basel) (2023)

- Carbon nanotubes for flexible batteries: recent progress and..., Zhu et al., National Science Review (2021)

Contributors

Written by

Application Scientist

Diagrams by

Graphic Designer