Graphene Battery vs Lithium-Ion Battery

Jump to: Pros and Cons | Performance comparison | Material Properties | Li-ion Batteries | Graphene Batteries | Making Hybrid Graphene Lithium-Ion Batteries

Lithium-ion (Li-ion) batteries, developed in 1976, have become the most commonly used type of battery. Comprised of cathode active materials such as lithium iron phosphate (LiFePO4) powder and lithium cobalt oxide, they are used to power devices from phones and laptops to electric vehicles and solar energy storage systems. However, the limitations of Li-ion batteries are becoming increasingly noticeable. Despite their high charge capacity and low manufacturing costs, Li-ion batteries suffer from low energy density, slow charging times, short lifespans, and significant safety risks, including the potential for fires.

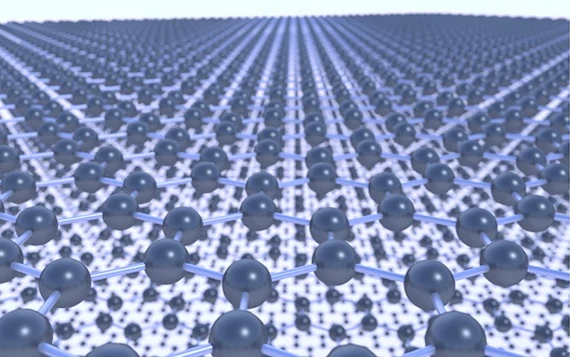

Graphene, a 2D material discovered in 2004, has transformed battery technology. Incorporating graphene materials into Li-ion batteries can alleviate many of their limitations and introduces new benefits, such as the possibility for flexible batteries. Graphene-enhanced batteries offer fast charging, high energy density, extended lifetimes, and crucially, are less flammable. One important distinction to make is that when we talk about graphene batteries, we are talking about batteries that use graphene in any way. Therefore, graphene batteries can also be lithium-ion batteries.

Graphene’s unique properties, such as high surface area, exceptional conductivity, and flexibility, make it an ideal material for next-generation batteries. Most commonly used in the electrodes of a conventional battery setups, graphene has rapidly advanced to become a viable and superior option to the typical Li-ion battery.

Graphene Battery vs Standard Lithium-Ion Pros and Cons

Lithium-ion batteries (LIBs) and those enhanced by the incorporation of graphene have a variety of advantages and disadvantages. Whilst there are many benefits to including graphene within a battery formulation, some financial drawbacks must be considered:

| Standard Li-Ion Battery | Graphene Battery | |||

|---|---|---|---|---|

|

Advantages |

|

|

|

|

|

Disadvantages |

|

|

|

|

Graphene Materials

Performance comparison: Li-Ion vs Graphene Battery

A battery's performance is influenced by several key properties, such as charge capacity, energy density, and lifetime. Optimizing these parameters can significantly enhance a battery’s overall operation. Although graphene batteries have only been researched since 2011, they are already demonstrating superior performance compared to traditional Li-ion batteries in many areas.

| Definition | Lithium-Ion Battery | Graphene-Enhanced Battery | |

|---|---|---|---|

|

First device |

1976 | 2011 | |

|

Charge capacity (milliamp-hours / mAh) |

The amount of chemical energy stored within the battery |

~ 2700 - 3300 mAh |

~ 1000 mAh |

|

Charging speed |

How fast the battery can be fully recharged |

1-2 hours |

27 minutes |

|

Energy Density (watt-hours per kilogram / Wh kg-1) |

The amount of energy the battery can store per unit mass. |

~250 Wh kg-1 |

~1000 Wh kg-1 |

|

Lifetime |

The number of times the battery can be fully recharged whilst maintaining at least 80% of its original capacity. |

~ 500 |

~ 2500 |

|

Safety |

Some batteries can overheat causing fires. |

Flammable |

Non-flammable |

|

Sustainability |

Many battery components include materials that must be mined and are hazardous, making recycling difficult. |

Mined |

Lab-grown |

Material Density and Surface Area

Battery performance depends strongly on the materials it is made of and the properties of each material. The properties that have significant effects on a battery's performance are material density and surface area.

Material density is a material's mass per unit volume. In battery materials, higher densities often mean there is more material for charge storage but this also makes the battery heavier. Lithium has a high density of 530 mg cm-3. Whilst graphene has a considerably lower density of 0.77 mg cm-2. As graphene is a 2D material, it's height dimension is almost negligible. Therefore this is often called the planar density and given as a mass per unit area. A lower density means batteries can be more lightweight which is particularly desirable for electric vehicle (EV) applications.

However, graphene has a much higher surface area than Lithium. Surface area is the total area of all faces of the material per unit mass. High surface areas mean there are more active sites for redox reactions to occur. In other words, this is the amount of available surface area per 1 g of material. In turn, this means faster charging. Lithium's surface area is 4 m2 g-1 , whereas graphene's surface area is over 650 times this at 2630 m2 g-1. For context, 1 gram of can cover a single table tennis top, whereas 1 gram of graphene is enough to cover about 10 full-sized tennis courts.

Li-Ion Batteries

Lithium-ion (Li-ion) batteries were first developed in 1976 and have become the most commonly used type of battery. Li-ion batteries can be found in phones, laptops, cameras, electric vehicles and solar energy systems. The broad application of Li-ion batteries shows their success, but they have upcoming competition.

Why use Lithium-ions In Batteries?

Li-ion batteries, called this due to the lithium ions used in the electrolyte, revolutionized battery technology. The Li-ion battery development lead to slim smartphones and electric vehicles. As of 2022, Li-ion batteries were responsible for 40% of the global battery market which reflects the recent increase in electric vehicles. Prior to Li-ion, nickel-cadmium (Ni-Cd) batteries were most popular. Lithium replaced Ni-Cd batteries due to its superior advantages, most of which relate to its small size.

- Lithium is the lightest metal in the periodic table. Lithium’s density is roughly 18 times lower than that of Ni and Cd at only 0.53 g cm-3. Lithium’s light weight made it a popular choice for many applications, in particular consumer devices.

- Lithium’s lower electronegativity also offered advantages to batteries. Electronegativity is the ability to attract electrons. Its values are given within the range of 0 to 4. Lithium has a low electronegativity of 0.98, whereas both Ni and Cd lie closer to 2. The low electronegativity means Li can easily lose electrons which encourages faster ion transfers and can help with faster charging times. Li-ion batteries were also reported to retain charge for longer than their Ni-Cd predecessors.

- It is important to note that lithium is considered a hazardous material. However, cadmium poses a significantly higher risk to both human and environmental health. Therefore, at the time lithium was considered a less toxic option.

Disadvantages of Li-Ion Batteries

Whilst lithium-ions are excellent charge carriers, with high redox activity, suited to energy storage, they do suffer from issues of degradation. When lithium-ions are collected at the anode, instead of intercalating with the anode material, they can sometimes react with other lithium-ions to form metallic lithium. This means they are no longer storing energy, leading to poor battery performance. The metallic lithium can also lead to more dangerous outcomes such as battery shorting, overheating and even fires. This often referred to as thermal runaway as when the process of overheating starts it tends to continue uncontrollably.

Battery Materials

Graphene Batteries

Graphene was only discovered in 2004 but rapid advancements have made it a welcome addition or alternative to the sole Li-ion battery. Graphene is most popularly used in the electrodes of conventional battery setups, but can also be combined into electrolytes or as additional interlayers.

Why Use Graphene in Batteries?

Graphene is a 2D material consisting only of carbon. It exists in thin sheets with the carbon atoms arranged in a honeycomb type structure. Although graphene is a relatively new material compared to lithium, its advantages have been quickly recognized. By incorporating graphene into Li-ion batteries, most often at the electrodes, many battery properties can be improved. Graphene batteries outperform traditional Li-ion batteries in terms of energy density and charging speed. Graphene batteries also offer new features such as being flexible and non-flammable.

Electrodes are one of the most influential parts of a battery. At the electrodes the redox reactions take place, these provide the chemical energy to make the battery work. Therefore a material that can efficiently transfer charge is a good material for an electrode. The high surface area of graphene make it an excellent candidate for this. A large surface area means more active sites for redox reactions to occur and so faster charging.

The benefits of graphene batteries have been widely recognized. Graphene batteries are under rapid development with applications in consumer electronic, such as phones and laptops. The thermal stability of graphene batteries render them a great choice for electric vehicles. More advanced applications such as satellites and battery-supercapacitor hybrids are also being explored.

Disadvantages of Graphene Batteries

Despite the considerable advancements in graphene battery technology, they are not yet ready for the market. A hindrance of graphene batteries is their low charge capacity compared to Li-ion batteries. A higher charge capacity means more chemical energy can be stored and therefore more electrical energy can be withdrawn.

As graphene is a lab-made material, fabrication costs are high. To make high purity graphene with minimal defects, energy intensive methods are required and these are therefore expensive. This also limits it's current scalability.

Making Hybrid Graphene Lithium-Ion Batteries

Graphene materials are not typically used as commercial electrode materials for lithium-ion batteries (LIBs) due to its low coulombic efficiency, high charge-discharge platform and poor cycle stability. However, due to their excellent electrical conductivity they have been employed as the material support, material mediator, electrode framework, or electrode modifier within composite electrodes.

Graphene in Cathodes for LIBs

Graphene materials within cathodes have been found to significantly improve cathode electrochemical performance. The large surface area of their two-dimensional structure and excellent electron transfer capability is effective in improving the overall electron and ion transmission and diffusion abilities within cathodes.

For example, lithium manganese oxide (LiMn2O4) and reduced graphene oxide hybrid cathode materials with high-rate capacity have been synthesized via microwave-assisted hydrothermal method at 200 °C for 30 min without any post heat-treatment. The nano-sized LiMn2O4 particles were evenly dispersed on the reduced graphene oxide template without agglomeration, which allows the inherent high active surface area of individual LiMn2O4 nanoparticles in the hybrid. These unique structural and morphological properties of LiMn2O4 on the highly conductive reduced graphene oxide sheets in the hybrid enable achieving the high specific capacity, an excellent high-rate capability and stable cycling performance.

Electrochemically exfoliated graphene sheets dispersed in DMF were added dropwise to carbon coated LiFePO4 powder with gentle stirring. Van der Waals forces formed between graphene sheets and the LFP particles. This helps to protect the cathode active material from volume expansion and agglomeration leading to increased specific capacity ranging from 187-208 mAh g-1 depending on the level of doping.

Other methods of graphene material cathode composite preparation include:

Self-assembly approach

Wet chemical method

Mechanical mixing

Micro-emulsion and ball-milling routes

Solvothermal synthesis

Wet ball milling and spray drying

Graphene in Anodes for LIBs

The addition of graphene materials to anodes in LIBs has resulted in superior electrical conductivity, due to their high surface area (2620 m2 g-1), high surface-to-volume ratio and ultra-thin thickness which can shorten the diffusion distance of ions. The structural flexibility of graphene materials has allowed for the creation of flexible electrodes. Thermal and chemical stability has also enhanced anode durability in harsh environments. Graphene materials are doped within anode mixtures to protect anodes from rupturing which leads to poor cycling performance.

Graphene has been used to modify tin based anode mixtures, accommodating the volume change of Sn during chare-discharge cycles. Graphene also contributes to improved electron transport, enhancing overall battery performance. The tin-graphene composite was made via hydrothermal synthesis and subsequent thermal annealing.

Hydrothermal Synthesis of Sn@C/GNS Composite

- SnO₂ Colloid Formation: Aqueous SnO2 nanoparticles were produced by slowly adding NaOH to SnCl4 solution over 12 hours with vigorous stirring.

- Composite Assembly: 0.2499 g of GNSs was ultrasonically dispersed in ethylene glycol. SnO2 colloid and glucose (carbon source) were added and mixed thoroughly.

- Hydrothermal Treatment: The mixture was sealed in an autoclave and heated at 180 °C for 12 hours.

- Post-treatment: Product was washed, dried at 70 °C, then annealed at 500 °C under argon to yield the final Sn@C/GNS composite.

Graphene can also be used to modify transition metal oxide-based anode materials with high lithium storage capacity. Due to their low relative conductivity and volume changes during charge and discharge, graphene is used to improve the electrochemical properties of transition metal oxides by preventing agglomeration and improving conductivity. Hydrothermal synthesis methods are also employed to fabricate graphene–transition metal composite anodes.

A novel method has been developed in which titanium dioxide (TiO2) is used to exfoliate graphite into multilayer graphene (MLG), avoiding the need for traditional solution-based techniques. In this process, TiO2 acts mechanically to break down graphite into graphene layers, which then wrap around SiOx particles to form a SiOx/TiO2@MLG composite.

The MLG significantly enhances the electrical conductivity of the anode, reduces electrolyte decomposition, and buffers the volume changes that typically affect silicon-based materials. TiO2 not only assists in the exfoliation of graphite but also contributes to the structural stability of the composite. Meanwhile, SiOx serves as the high-capacity active material for lithium storage.

This engineered composite delivers a high specific capacity of 1484 mAh g-1, maintains performance over 1200 cycles at a current density of 2 A g-1, and shows strong results in full-cell lithium-ion batteries paired with nickel-rich cathodes.

Learn More

Graphene Batteries

Graphene Batteries

Graphene batteries are advanced energy storage devices. Graphene materials are two-dimensional and are typically made solely of carbon.

Read more...Solid-state batteries (SSBs) differ from conventional lithium-ion batteries (LIBs) in terms of both their components and fundamental design features. Instead of a liquid electrolyte, they use a solid electrolyte to conduct lithium ions between electrodes.

Learn more...

References

- AA Battery Voltage Chart: Understanding the Power Behind..., Klein, Electro University (2024)

- GMG’s Graphene Aluminum-Ion Battery: 1000 mAh Capacity Reached..., GMG Management, GMG News (2024)

- 1C Charging Speed Of Lithium Batteries: A Necessity..., Karimov, OneCharge (2020)

- Elecjet fast charging 10,000mAh battery pack, Horsey, Geeky Gadgets (2021)

- An Outlook on Lithium Ion Battery Technology, Manthiram, ACS Central Science (2017)

Contributors

Written by

Scientific Writer

Diagram by

Graphic Designer

Edited by

Application Scientist

Application Scientist