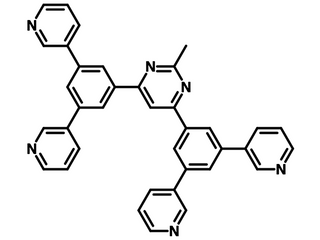

B3PymPm

CAS Number 925425-96-3

Charge Transport Layer Materials, Electron Transport Layer Materials, High Purity Sublimed Materials, Materials,B3PymPm, ETL and HBL material in OLED devices

Paired with TCTA to be used in TADF devices to fabricate highly-efficient fluorescent OLEDs, CAS No. 925425-96-3, 4,6-Bis(3,5-di(pyridin-3-yl)phenyl)-2-methylpyrimidine, 4,6-Bis(3,5-di-3-pyridinylphenyl)-2-methylpyrimidine

Overview | Specifications | | MSDS | Literature and Reviews

B3PymPm is an isomer to B2PymPm and B4PymPm, with a 2-methylpyrimidine core structure with four pyridine pendants. It is electron-deficient and can be used in OLED devices as an electron-transporting or hole-blocking layer material.

B3PymPm is known to form hydrogen bonding in and between molecules. The intermolecular and intramolecular hydrogen bonding are believed to promote film morphology - hence enhancing charge mobility.

Due to its electron-deficient nature, together with TCTA, B3PymPm is also used in thermally activated delayed fluorescent (TADF) devices as an exciplex-forming co-host to fabricate highly-efficient fluorescent organic light-emitting diodes.

General Information

| CAS number | 925425-96-3 |

|---|---|

| Full name | 4,6-Bis(3,5-di(pyridin-3-yl)phenyl)-2-methylpyrimidine, 4,6-Bis(3,5-di-3-pyridinylphenyl)-2-methylpyrimidine |

| Chemical formula | C37H26N6 |

| Molecular weight | 554.64 g/mol |

| Absorption* | λmax 248 nm in DCM |

| Fluorescence | n/a |

| HOMO/LUMO | HOMO = 6.97 eV, LUMO = 3.53 eV [1]; ET1 = 3.08 eV |

| Classification / Family | Pyrimidine derivatives, Highly efficient light-emitting diodes, Organic electronics, Electron-transport layer (ETL) materials, Hole-blocking layer (HBL) materials, Sublimed materials. |

* Measurable with an optical spectrometer

Product Details

| Purity | Sublimed >99.0% (HPLC), unsublimed >98.0% |

|---|---|

| Melting point | 326 °C |

| Appearance | White crystals/powder |

* Sublimation is a technique used to obtain ultra pure-grade chemicals, see sublimed materials.

Chemical Structure

Device Structure(s)

| Device structure | ITO/15 wt.% Rb2CO3:B3PymPm (20 nm)/B3PymPm (30 nm)/8 wt.% Ir(ppy)3:CBP (15 nm)/TAPC (30 nm)/8 wt.% ReO3:TAPC (20 nm)/Al [2] |

|---|---|

| Color | Green |

| Max. Power Efficiency | 79.8 lm W−1 |

| Max. EQE | 19.8% |

| Device structure | ITO (150 nm)/TAPC (20 nm)/TCTA (10 nm)/TCTA:B3PYMPM:Ir(mphq)2(acac) (5 nm, 3 wt%)/TCTA:B3PYMPM:Ir(ppy)2(acac) (25 nm, 8 wt%)/B3PYMPM (45 nm)/LiF (0.7 nm)/Al (100 nm) [3] |

|---|---|

| Color | Orange |

| Max. Power Efficiency | 70.1 lm W−1 |

| Max. EQE | 22.8% |

| Device structure | ITO (70 nm)/ TAPC (75 nm)/TCTA (10 nm)/TCTA:B3PYMPM:4 wt % Ir(dmppy-pro)2tmd* (30 nm)/B3PYMPM (45 nm)/LiF (0.7 nm)/Al (100 nm) [4] |

|---|---|

| Color | Green |

| Max. Current Efficiency | 126 cd/A |

| Max. EQE | 36.0% |

| Device structure | ITO (70 nm)/ TAPC (75 nm)/TCTA (10 nm)/TCTA:B3PYMPM:4 wt % Ir(dmppy-ph)2tmd* (30 nm)/B3PYMPM (55 nm)/LiF (0.7 nm)/Al (100 nm) [4] |

|---|---|

| Color | Yellow |

| Max. Current Efficiency | 108 cd/A |

| Max. EQE | 38.1% |

| Device structure | ITO (70 nm)/TAPC ( 80 nm)/TCTA (10 nm)/TCTA:B3PYMPM:8 wt% Ir(ppy)2(acac) (30 nm)/B3PYMPM (40 nm)/Al (100 nm) [5] |

|---|---|

| Color | Green |

| Max. Current Efficiency | 127.3 lm W−1 |

| Max. EQE | 30.2% |

| Device structure | ITO (70 nm)/TAPC (75 nm)/TCTA (10 nm)/TCTA:B3PYMPM:8.4 mol% Ir(ppy)2tmd* (30 nm)/B3PYMPM (45 nm)/LiF (0.7 nm)/Al (100 nm) [6] |

|---|---|

| Color | Green |

| Max. Current Efficiency | 142.5 lm W−1 |

| Max. EQE | 32.3% |

*For chemical structure information, please refer to the cited references

MSDS Documentation

Literature and Reviews

- Development of high performance OLEDs for general lighting, H. Sasabe et al., J. Mater. Chem. C, 1, 1699 (2013); DOI: 10.1039/c2tc00584k.

- A high performance inverted organic light emitting diode using an electron transporting material with low energy barrier for electron injection, J. Lee et al., Org. Electron., 12, 1763–1767 (2011); doi: 10.1016/j.orgel.2011.07.015.

- High efficiency and non-color-changing orange organic light emitting diodes with red and green emitting layers, S. Lee et al., Org. Electron., 14, 1856–1860 (2013); doi: 10.1016/j.orgel.2013.04.020.