PTAA or Spiro-OMeTAD? Choosing a HTL for your Solar Cells

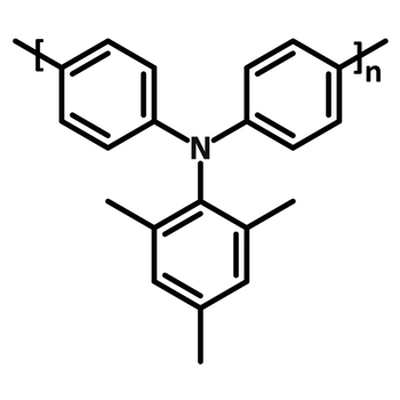

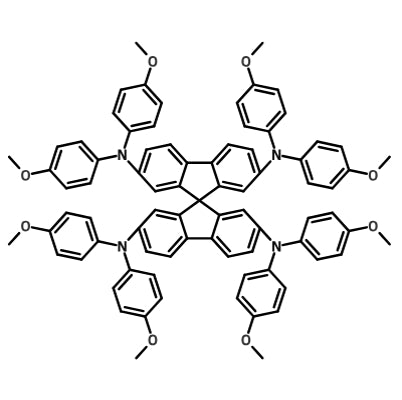

Poly[bis(4-phenyl)(2,4,6-trimethylphenyl)amine] (PTAA) and 20,7,70-tetrakis[N,N-di(4-methoxyphenyl)amino]-9,90-spirobifluorene (Spiro-OMeTAD) are both used as hole transport layers in high efficiency perovskite solar cells (PSCs). Regular architecture devices using PTAA and Spiro-OMeTAD layers have demonstrated power conversion efficiencies (PCEs) of over 22% and 25% respectively. Additionally, inverted p-i-n devices using PTAA have achieved PCE exceeding 25%.

As both materials can produce high efficiency solar cells, whether you should choose PTAA or Spiro-OMeTAD will depend on:

- What other layers are in your device

- Your device architecture (regular or inverted)

- Your testing environment

- Your perovskite composition

Spiro-OMeTAD and PTAA share some advantages and limitations when used as a hole transport layer. For a detailed analysis of both materials we would recommend reading the review by Rombach et al. cited in the References. This page will provide a quick overview of both Spiro-OMeTAD and PTAA, suggesting why you would choose one over the other.

Overview

Material Properties

| PTAA | Spiro-OMeTAD | |

|---|---|---|

| Energy Offset (HOMO from perovskite valence band) | 100s meV | 100s meV |

| Hole Mobility |

Good (Slightly Higher than Spiro-OMeTAD) |

Good (Slightly Lower than PTAA) |

| Conductivity (doped) | Similar | Similar |

| Overall HTL Performance | Similar

(when sufficiently doped) |

Similar

(when sufficiently doped) |

Dopants

| PTAA | Spiro-OMeTAD | |

|---|---|---|

| Dopants used |

LiTFSI, tBP BCF |

LiTFSI, tBP, Fk209 |

| Relative Doping Concentrations Required | Low | High |

| Is Oxidation Required? | No | Yes |

Device Performance

| PTAA | Spiro-OMeTAD | |

|---|---|---|

| Suitable for n-i-p devices? | Yes | Yes |

| Suitable for p-i-n devices? | Yes | No |

| Champion PCE (as of 2023) | >25% (Inverted Device) | > 25% (Regular Device) |

Device Stability

| PTAA | Spiro-OMeTAD | |

|---|---|---|

| In high moisture environments (98% RH) | Improved Stability | LowerStability |

| Under Nitrogen at High Temperatures | Improved Stability | Lower Stability |

| Under Nitrogen, In Operational Conditons | Improved Stability | Lower Stability |

| In Air at High Temperatures | Lower Stability | Improved Stability |

| In High Temperature, High Moisture Environments | Reduced Stability | Improved Stability |

| Overall | Dopant dependent

Requires improvement |

Dopant dependent

Requires improvement |

Spiro-OMeTAD

Using Spiro-OMeTAD as a hole transport layer helped facilitate the first completely solid state perovskite solar cell. Ever since, Spiro-OMeTAD has been used as the HTL for some of the highest efficiency PSCs. It is an excellent hole transport material because:

- it can be easily solution processed

- it has good energy level alignment with most perovskite materials (100s meV energy offset between it's highest occupied molecular orbit and the valence band of most perovskite material)

- With appropriate dopants, it has very good conductivity.

Spiro-OMeTAD is usually doped with additives such as LiTFSI, Fk209 and 4-tert-Butylpyridine (tBP), to improve its hole transport properties. LITFSI and Fk209 increase conductivity and tBP improves film morphology, wetting and uniformity. Additionally, spiro-OMeTAD requires oxidation to make Spiro-OMeTAD+. Using doped Spiro-OMeTAD, you can easily and reliably produce a high efficiency solar cell.

However, there are a few issues with this materials. One of the solvents that will dissolve Spiro-OMeTAD is DMF, a common solvent for perovskite material. The deposition of the perovskite layer onto the spiro layer is likely to result in the dissolution of Spiro-OMeTAD. Therefore, spiro-OMeTAD can't be used for inverted devices.

Spiro-OMeTAD also has some stability issues when used in perovskite solar cells. These devices have shown vulnerability to high temperatures, including significant degradation at 85°C (a key milestone for solar cell stability). These problems may arise from dopants or the way Spiro-OMeTAD interacts with other device layers.

Suggested degradation mechanisms include:

- Dopant molecules (such as Li+) migrate from the Spiro-OMeTAD layer into the perovskite film

- Ions from the metal contact travel through the thin spiro-OMeTAD layer into other layers

- tBP degrades the Spiro-OMeTAD layer, reducing the conductivity of Spiro-OMeTAD over time. This degradation, and therefore the material conductivity, depends on temperature, illumination, aging and tBP concentration.

- Spiro-OMeTAD requires a high concentration of dopants to function well, so any dopant based degradation is very significant in Spiro-OMeTAD films.

PTAA

PTAA (for perovskites) is an alternative HTL to spiro-OMeTAD, used in perovskite solar cells. PSCs using PTAA have achieved high PCEs. In some ways, these devices show improved device stability compared to other hole transport layers. Only a very thin layer of PTAA is needed for PSCs, indicating better film coverage and hole transfer between the PTAA and perovskite layers. PTAA makes a good hole transport material because:

- It can be solution processed

- It has high transmittance in the visible region

- It has impressive hole mobility properties

- It has a good energetic match with most perovskites (again with only 100 meV energy offset)

- It has good thermal stability in devices, with no glass transition or melting behavior up to 300°C

PTAA is also doped to improve its HTL properties. It can be doped with LiTFSI and tBP, like Spiro-OMeTAD. The roles of these dopants in PTAA are not well understood, but it is likely that they improve conductivity and film morphology as they do in Spiro-OMeTAD. PTAA can also be doped with alternative dopants, such as BCF, providing closer energy alignment with perovskite valence bands while increasing hole mobility and conductivity.

In terms of stability, devices using PTAA have good thermal stability under nitrogen and in high moisture environments. However, devices using PTAA degrade quickly under high temperatures in air, faster than those using Spiro-OMeTAD. These stability issues have also been linked with LiTFSI and tBP. Some studies show that using alternative dopants (namely BCF) reduces this degradation.

Some of the suggested degradation mechanisms include:

- Interaction with LiTFSI and tBP dopants degrades the PTAA layer

- Migration of dopant molecules (e.g. Li+) into other device layers

- Migration of ions through the thin HTL layer into other layers of the device, or out of the device completely.

PTAA or Spiro-OMeTAD?

There are many things to consider when choosing PTAA or Spiro-OMeTAD.

Hole Transport Properties

The exact hole transport properties of a hole transport layer depend on many things including:

- The type and concentration of dopants used

- The other layers in the device

- Device architecture

- Active layer composition.

However, studies have found some key differences between PTAA and Spiro-OMeTAD. Spiro-OMeTAD has higher hole transfer rates than PTAA. However, PTAA seems to have lower rates of interfacial recombination. Undoped Spiro-OMeTAD has slightly higher hole mobility than PTAA, but when doped their conductivity and hole mobility properties are basically the same.

There is a slight energy offset between the HOMO level for both these hole transport materials and the perovskite valence band. Both of these lie within 100 meVs of ideal band alignment. There will be a small amount of VOC lost due to this misalignment.

Film Morphology

PTAA layers can be much thinner than Spiro-OMeTAD layers and still have great hole transport properties. This implies that PTAA layers have a better overall film morphology, forming better contact with the perovskite layer.

Dopants

PTAA and Spiro-OMeTAD both require doping. LiTFSI and tBP can be used to dope both of these hole transport materials. However, these dopants lead to problems in device stability. These dopants should be replaced if either are to make efficient perovskite devices. Spiro-OMeTAD requires a higher dopant contentration (particularly of LiTFSI), so dopant instabilities have a relatively bigger impact on device stability.

PTAA can be doped with other materials such as BCF, which appears use a different doping mechanism to LiTFSI and tBP combinations. These devices show improved stability. As of yet, there is not an better alternative for LiTFSI and tBP in Spiro-OMeTAD devices.

Device performance

In n-i-p devices, Spiro-OMeTAD devices outperform PTAA-based devices. However, there is not much difference between these performances. Also Spiro-OMeTAD devices require aging and oxidation to reach peak performance. PTAA devices don't require this.

Device Stability

LiTFSI and tBP cause stability issues in both Spiro-OMeTAD and PTAA films. PTAA stays amorphous at higher temperatures than Spiro, so devices perform better at higher temperatures. PTAA also provides better moisture protection. Under operational conditions and high temperatures, PTAA-perovskite devices are more stable than those using Spiro-OMeTAD.

PTAA outlasts Spiro-OMeTAD under inert conditions. However, devices using PTAA generally perform worse in air than devices using Spiro-OMeTAD.

Inverted (p-i-n) vs. Standard (n-i-p) Devices

For inverted p-i-n devices, the HTL must be deposited before the perovskite layer. This places additional requirements on the HTL as it must not be dissolved by the solvents which contain the perovskite precursors (primarily DMF and DMSO). Spiro-OMeTAD therefore cannot be used in inverted architecture devices.

PTAA is not dissolved by DMF or DMSO, so it can be used in inverted architecture devices. It also has good light transmittance which is very important for inverted architecture devices.

Wettability is an issue, but this can be improved by prewetting the surface, solvent engineering, or using interlayers between the PTAA and perovskite.

Summary

PTAA and Spiro-OMeTAD are both suitable hole transport layers for perovskite solar cells. Although there are slight differences, their hole transport properties are generally comparable. Overall, PSCs using spiro-OMeTAD have better device performances, but in some areas devices using PTAA have improved stability.

There are a few factors to consider when choosing Spiro-OMeTAD or PTAA for your devices, including:

- Perovskite composition

- Device structure

- Other device layers

Both materials can provide good hole transport properties, providing they have a optimized deposition procedure and align well with your chosen perovskite material. Both PTAA and Spiro-OMeTAD require the use of dopants to achieve their highest performances. These dopants can lead to performance and stability issues, so further research is required to replace or optimize dopant use for both HTL materials.

Materials Mentioned

Learn More

The rapid improvement of perovskite solar cells has made them the rising star of the photovoltaics world and of huge interest to the academic community.

Read more... The Ultimate Guide to Making Perovskite Solar Cells

The Ultimate Guide to Making Perovskite Solar Cells

Over the past 10 years, perovskite solar cells (PSCs) have achieved record efficiencies of 25.5% single junction solar cells (as of 20211) and these efficiencies are rising impressively.

Read more...References

- Rombach, F. M., Haque, S. A., & Macdonald, T. J. (2021). Lessons learned from spiro-OMeTAD and PTAA in perovskite solar cells. Energy and Environmental Science, 14(10), 5161–5190. DOI: /10.1039/d1ee02095a

- Wang, Y., Duan, L., Hameiri, Z., Zhang, M., Liu, X., Yang, B., & Hao, X. (2022). PTAA as Efficient hole Transport Materials in Perovskite Solar Cells: A review. Solar RRL, 6(8). DOI: 10.1002/solr.202200234

- Zhang, B., Lin, H., Qiu, X., Shui, Q., Zheng, Y., Almesfer, M., Kauppinen, E. I., Matsuo, Y., & Maruyama, S. (2023). Spiro-OMeTAD versus PTAA for single-walled carbon nanotubes electrode in perovskite solar cells. Carbon, 205, 321–327. DOI:10.1016/j.carbon.2023.01.011