Factors Influencing OPV Stability

Condensed Summary

Title: Fundamentals of bulk heterojunction organic solar cells: An overview of stability/degradation issues and strategies for improvement.

Citation: S. Rafique et al., Renew. Sust. Energ. Rev. (84), 43-53 (2018).

DOI: 010.1016/j.rser.2017.12.008

Learning point: Bulk heterojunction organic solar cells are susceptible to a wide range of degradation mechanisms, including both obvious extrinsic factors, such as oxygen and humidity, and intrinsic factors. Encapsulation alone is not always sufficient to produce stable devices

The Stability of Organic Photovoltaics

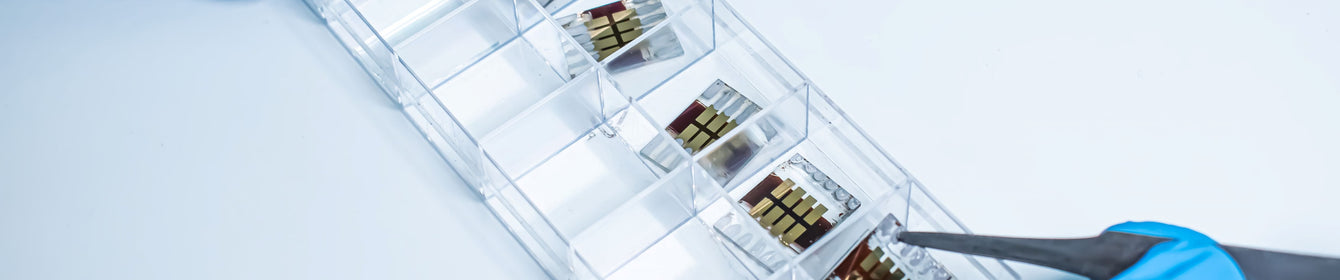

Typically, organic photovoltaics (OPVs) are manufactured in the form of a bulk heterojunction (BHJ) cell, where the active layer consists of a blend of donor and acceptor materials with various interfacial layers and electrodes (seen in Figure 1). For OPVs to be commercially competitive with existing solar technologies, a ’10/10’ target must be reached, which refers to a 10% power conversion efficiency (PCE) and 10-year lifetime. Whilst the 10% PCE target has now been significantly exceeded by many groups,2 stability studies assessing the operational lifetime of OPVs still lag behind.

Whilst accelerated stability tests have extrapolated OPV lifetimes of up to 15 years,3 the conditions used are not fully representative of those experienced in outdoor installations. Even vigorous indoor testing (such as damp heat testing) does not incorporate the daily and seasonal fluctuations of temperature and light intensity that occur in an outdoor setting. Several outdoor stability studies that have attempted to replicate real-life conditions,4–7 but these have mostly been confined to the period of a year, and are therefore difficult to extrapolate accurately to longer periods of operation.

It is clear that further research needs to take place to extend the operational lifetime of OPVs. For this to be successful, there needs to be a deeper understanding of the mechanisms behind degradation. There have been several reviews published on this topic8,9 — the most recent being by Rafique and co-workers,1 which is discussed here.

Lifetime Testing

Most OPVs will show a ‘burn-in’ upon initial testing. This refers to an exponential loss of efficiency (the length of which varies between systems, but is often within the first 100 hours) followed by a linear decay. After the burn-in period, PCE typically stabilizes at an efficiency around 25–50% of the initial value.10 Generally, the ‘lifetime’ of an OPV refers to its T80, meaning the time taken for the PCE of a device to reach 80% of its post burn-in efficiency.11 The exact mechanism of efficiency loss during the burn-in period has not yet been completely established, but has been variously attributed to the generation of sub-band gap states,12 fullerene dimerization,13 and other factors.

PCE can be measured through the use of the solar cell I-V test system along with the solar simulator.

Emma’s comments: It is worth noting that recently a ‘burn-in free’ OPV was shown10 using a non-fullerene acceptor (NFA). Indeed, many of the degradation mechanisms of OPVs can be attributed to fullerene,14 and it seems likely that NFAs hold an advantage over their fullerene counterparts - both in efficiency and stability.

The linear decay after burn-in can be attributed to a number of different inter-related mechanisms that often happen at the same time, leading to a complex system that is difficult to optimize. To encourage consistency between different research groups, the International Summit on OPV Stability (ISOS) have published established lifetime testing standards, and most stability tests will attempt to replicate one of the three levels of testing protocol.8

Extrinsic Degradation Factors

Rafique and co-workers divide the influences affecting degradation into both extrinsic factors (meaning environmental forces such as humidity and oxygen) and intrinsic factors (meaning the stability of the materials within the device itself).

Of the various extrinsic factors, oxygen and water are the most obvious. Oxygen causes photo-oxidation of layers within the device (especially the active layer), disrupts charge transport processes, and oxidizes some cathodes, forming an insulating metal oxide barrier layer. Typically, it has been found that oxygen content and loss in device performance are linearly related.9

In contrast, device performance has been found to exponentially decrease with relative humidity.9 Water causes corrosion of metal electrodes, induces morphological changes, and swells water-soluble layers — often resulting in delamination of layers within the stack (and eventual failure).

Emma’s comments: Encapsulation of OPVs is very common in research, often done using epoxy and glass coverslips over the top of the cathode to reduce the diffusion of oxygen and water into the device. However, this cannot prevent ingress through the sides of the stack (which is often accelerated by water-soluble layers like PEDOT:PSS) and is therefore not completely effective. Glass encapsulation is also not compatible with flexible OPVs, meaning there are still significant areas for improvement.

Morphological changes can encourage formation of pinholes in one layer, which will in turn increase diffusion of oxygen or water into the next layer, furthering device deterioration. Whilst encapsulation can reduce the impact of extrinsic factors, current encapsulants will not protect devices permanently.

Other extrinsic factors discussed by Rafique et al. include mechanical stress (particularly relevant for flexible OPVs), processing conditions, light, and temperature. The latter two factors are closely related, as extended illumination will raise the temperature of the device. This has been shown to cause thermally-induced fullerene aggregation, and light itself will encourage photo-oxidation and photogeneration of trap states. Little correlation has been found between light intensity and loss of device performance,9 but it is clear that even ambient lighting can introduce degradation mechanisms.14

Intrinsic Degradation

Low band-gap polymers (such as PTB7) have performed well in research, but have shown photochemical instability15 in comparison to other polymers such as P3HT. The materials used for interfacial layers (such as the hole-transport (HTL) and electron-transport layer (ETL)) will also be significant.

The most common HTL of all, PEDOT:PSS, shows intrinsic instabilities. It is acidic and hygroscopic, meaning it will absorb water, and encourage the diffusion of water into the device from the edges. As a result, it can corrode the commonly-used anode ITO, causing indium diffusion into the active layer,16 leading to accelerated charge recombination. This will occur even after encapsulation, and likely cannot be prevented with the use of PEDOT:PSS and ITO.

Other common materials (such as the ETL/cathode combination of LiF/Al) are very sensitive to oxidation, resulting in significantly unstable devices. Materials introduced into the stack (like solvent additives like diiodooctane (DIO)) can also cause degradation. DIO is light-sensitive and can be trapped by fullerene moieties or react with a conjugated polymer backbone, accelerating photo-oxidation of the active layer.17

Improving Stability

Intrinsic instability can be tackled in some ways via careful component choice. An example of this is tackling the indium diffusion at the ITO-PEDOT:PSS interface by either replacing the ITO,17 or replacing the PEDOT:PSS. Rafique and co-workers refer to alternative HTLs such as NiO, V2O5, WO3 and MoO3. Similarly, more stable ETL alternatives include CrOx, Cs2CO3 and TiO2, and in literature there has been a move away from Al electrodes to more stable Ag.

Emma’s comments: Eventual large-scale manufacture should be kept in mind when replacing components in OPVs, as highly efficient materials may not have good stability. Solution processable interfacial layers are more favorable as these can be incorporated into a roll to roll manufacturing process.

Conclusions

It is worth noting that degradation factors that affect solution-processed BHJ cells will not affect other types of OPV in the same way (such as planar heterojunction cells5 and roll-to-roll processed cells.6) This is significant as future commercialization of OPVs will likely require compatibility with roll-to-roll production, so stability in this context is particularly relevant.

It is likely that future work in improving OPV stability will focus on scalable manufacture, air-stable electrodes, suitable active-layer component choice, better encapsulation, and investigations that focus specifically on the mechanisms behind degradation (and how they can be prevented).

PEDOT Polymer Blends

Learn More

Organic Solar Cells: An Introduction to Organic Photovoltaics

Organic Solar Cells: An Introduction to Organic Photovoltaics

Organic solar cells, also known as photovoltaics (OPVs), have become widely recognized for their many promising qualities. This page introduces the topic of OPVs, how they work and their development.

Read more... Solar Cells: A Guide to Theory and Measurement

Solar Cells: A Guide to Theory and Measurement

A solar cell is a device that converts light into electricity via the ‘photovoltaic effect’. They are also commonly called ‘photovoltaic cells’ after this phenomenon, and also to differentiate them from solar thermal devices. The photovoltaic effect is a process that occurs in some semiconducting materials, such as silicon.

Read more...References

- Fundamentals of bulk heterojunction organic solar cells: An overview of stability/degradation issues and strategies for improvement, S. Rafique et al., Renew. Sustain. Energy Rev. (84), 43-53 (2018); DOI: 10.1016/j.rser.2017.12.008.

- Molecular Optimization Enables over 13% Efficiency in Organic Solar Cells, W. Zhao et al., J. Am. Chem. Soc. (139), 7148-7151 (2017); DOI:10.1021/jacs.7b02677.

- Minimal long-term intrinsic degradation observed in a polymer solar cell illuminated in an oxygen-free environment, W. R. Mateker et al., Chem. Mater. (27), 404-407 (2015); DOI: 10.1021/cm504650a.