Perovskite Solar Cells: Frequently Asked Questions (FAQ)

Our technical support team receive enquiries about perovskite solar cell or photovoltaic fabrication on a regular basis. For your convenience, we've collated some of the most common questions here which you may find helpful when using our perovskite materials such as our perovskite inks like I101 or I201 perovskite precursor inks.

Can't find the information you're looking for? Fill in our contact form and a member of our team will get back to you as soon as possible.

Which dehumidifier do you use in your lab to reduce the humidity to 30-40% rh?

We are currently using a 10L Igenix Portable dehumidifier, and find that this works very well for a small room with a recirculating fume hood (rather than an extracting fume hood). The volume of our perovskite lab is about 45 cubic meters (about 18 square meters with ceiling height of 2.5 meters).

How long will the Perovskite solutions be stable for?

The solutions are dissolved, stored, decanted and sealed in a nitrogen-filled glove box. The individual lots are packaged in a 2 ml amber vial with a PTFE cap, as seen below. They are securely fastened and an additional protective layer of parafilm is used around the lid. This should therefore allow the solutions to be stable in ambient conditions. Should you wish to store the solutions for a very long time (many months), then we would still advise storing the solutions in a nitrogen-filled glove box if possible.

How do I clean my equipment after spinning the Perovskite ink?

For spinning outside in air (i.e. I101), our technique is to clean the spin coater using a 10% NaOH solution. This cleanly and effectively removes any residue material. Please remember to clean the NaOH off with DI water afterwards.

Using I201 inside the glove box, we want to restrict the presence of moisture within the glove box. Therefore, using small quantities of neat DMF will efficiently remove the residue.

How do I remove the Perovskite film from certain areas on the substrate (i.e. for the deposition of the cathode)?

Our technique has been to wipe the substrate using a dry cleaning swab after spinning (for I101-based devices), or using a cleaning swab dipped in DMF (for I201 devices - note that devices should be on the hotplate during this particular process to prevent the DMF solution from seeping into the entire Perovskite film).

What is used to similarly remove the PC70BM layer?

A cleaning swab dipped in chlorobenzene (CB) is sufficient to remove the PC70BM film. This does not require the device to be on a hotplate as there is little risk of the CB solvent seeping into the rest of the PC70BM film.

Where should the Perovskite films be kept while preparing the PC70BM solution (which requires a few hours heating)?

The best routine we have employed is to prepare the PC70BM solution either at the start of the experiment (i.e. before cleaning substrates) or the night before. This will provide the solution ample time on the hotplate to dissolve prior to its use. It will also prevent the Perovskite films from having to experience any "storage" time and allow a fluent fabrication procedure to be performed.

What is the difference between the various substrate systems (i.e. pixelated anode substrate, pixelated cathode substrate and the Edgeless 8-pixel substrate systems)?

- The pixelated anode substrate system (S101) was our first substrate design enabling 6 pixels per device and originating from the world of OLEDs, which are higher voltage and lower current - meaning that series resistance is less important. Here, the pixels act as the anodes, while a cathode strip is thermally evaporated through a shadow mask to connect with the upper ITO strip for extracting electrons.

- The pixelated cathode substrate system (S171), on the other hand, has a single large area anode with multiple thermally evaporated cathodes. This re-design of the substrate system affords a greater degree of flexibility for the multitude of device architectures. It also provides a reduction in the sheet resistance of the substrate which is more important for PV than OLED as there is a much higher current density. However, we then improved this design further and it evolved into the 8 pixel edgeless photovoltaic substrate system.

- The edgeless 8 pixel photovoltaic substrate system (S211) (our newest design) capitalises on the flexibility and reduced sheet resistance from the pixelated cathode substrate system while enabling an additional 2 pixels per substrate. Furthermore, the design enables all pixels to exist in the center of the substrate, thereby removing the typical lower performing edge pixels. An additional benefit from removing the edge pixels is a reduction of potential edge ingress thus increasing device stability. As such, we currently recommend the edgeless 8-pixel substrates for PV devices.

Why should I101 be spun in air, rather than in a nitrogen/argon filled glove box?

We have found that humidity plays a crucial role during the spinning and annealing stages of the Perovskite device fabrication. Substrate coverage and wettability, as well as crystal formation are just a few considerations required for Perovskite films. Our Perovskite ink I101 has been specifically designed to perform best when processed and annealed in air (with a humidity of 30-40% rh).

Note that I201 is optimized for use in a glove box and performance is reduced by the presence of air.

Perovskite Materials

Learn More

Silicon is the most commonly used material in photovoltaic (PV) technology. In recent times perovskite materials have generated much excitement in the field of solar cell research. Here we discuss the pros and cons of each in addition to their use in conjunction with one another.

Read more... Perovskite Solar Cell Layers

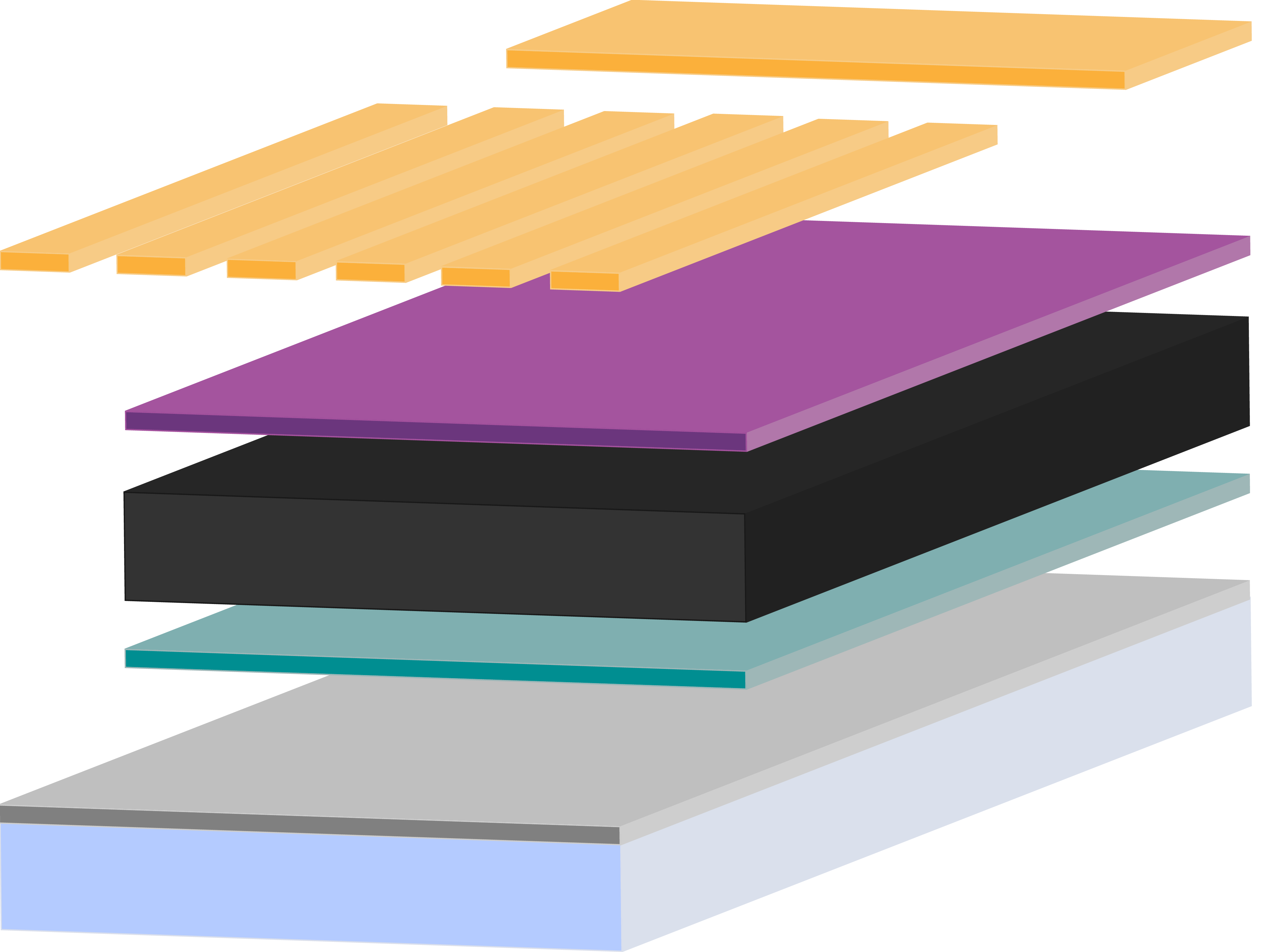

Perovskite Solar Cell Layers

Perovskite solar cells need several layers in order to absorb light, then separate and extract charge. In basic terms, a planar PSC needs an absorbing perovskite layer sandwiched in between a hole transport layer and an electron transport layer.

Read more...