Potentiostat

Electrical Characterization, Electrochemistry Supplies, Lab Equipment,Low Price Potentiostat for Cyclic Voltammetry and More

Available with electrochemical cell and electrodes for unbeatable value

Overview | Specifications | Software | Gallery | In the Box | Related Products | Resources and Support

Perform linear sweep voltammetry, cyclic voltammetry, open circuit potential, and controlled potential electrolysis, with the powerful Ossila Potentiostat. You can be confident in your measurements with excellent applied potential and current measurement accuracy and a high applied potential and current measurement resolution.

Whether you are an experienced chemist and or a newcomer to the field, the easy-to-use PC software makes it straightforward for anyone to take accurate and precise measurements across a wide potential and current range. Set the relevant parameters then watch the measurement as it happens with live data plotting.

Buy as a standalone instrument to use with any electrochemical cell, or choose the complete kit which includes electrochemical glassware, your choice of non-aqueous Ag/Ag+ or aqueous Ag/AgCl reference electrode, a platinum disc reference electrode, and a platinum wire counter electrode.

Affordable Characterization

Cyclic voltammetry and more

Powerful

Electronics

Potential range of ±7.5 V

Simple-to-Use

Software

Free PC software included

Add Electrochemical Cell and Electrodes

Available as a complete kit

How Does a Potentiostat Work?

A potentiostat controls the potential difference between two electrodes and measures the resulting current flow. It is able to vary its output potential (voltage) in response to changes in the resistance across a circuit. In electrochemistry experiments, potentiostats are able to supply more or less current so that the potential across an electrochemically active cell remains constant as per Ohm’s Law (voltage (V) = current (I) x resistance (R)).

A potentiostat is essential for the characterization of electrochemical processes, which is directly relevant to applications in sensing, electronics, and battery research.

A potentiostat applies a potential to the working electrode, which is held at a defined voltage relative to the reference electrode. The surface of the working electrode is the primary area of interest because, under an applied potential, the number of electrons at its surface changes (increases or decreases).

The applied potential alters the electrochemical potential of the working electrode, making oxidation or reduction thermodynamically favorable. This drives the exchange of electrons between the electrode and species in the electrolyte. The specifics of this electron exchange depends on the chemical system under investigation. The current flows in the opposite direction to the flow of electrons within the circuit.

The measured current is the exchange of electrons per time at the electrodes surface. The current flows between the working electrode and counter electrode (in a three electrode set up).

Measuring current as a function of potential helps identify the point at which electron transfer is most efficient. This reveals key information about redox behavior, analyte concentration, and electrode performance. These characteristics are key to understanding and optimizing electrochemical reactions.

Key Specifications

| Potential Range | ±7.5 V |

|---|---|

| Potential Compliance | ±10 V |

| Applied Potential Accuracy | ±10 mV offset |

| Applied Potential Resolution | 333 µV |

| Scan Rate Range | 5 mV/s to 1000 mV/s |

| Maximum Current | ±200 mA |

| Current Ranges | ±20 μA to ±200 mA (5 ranges) |

| Current Measurement Accuracy | ±20 nA offset (at 20 μA range) |

| Current Measurement Resolution | 5 nA (at 20 μA range) |

| Communication | USB-B |

| Overall Dimensions (W x H x D) | 125 mm x 55 mm x 175 mm (4.91" x 2.17" x 6.89") |

| Weight | 600 g (1.32 lb) |

The Ossila Potentiostat is small, portable and easy to use. We also bought the three electrode cell and this provides a stable set-up to hold the electrodes in convenient positions.

Top automotive manufacturer

Specifications for Current Measurements

Current is the key measurement parameter for the potentiostat. It it important to know the requirements regarding this essential measurement. The current measurement by a potentiostat must fall within the maximum current with specific accuracy and resolution assigned to specific current ranges.

Specification

Description

Maximum current

The highest electrical current that can be measured by a potentiostat for both positive and negative currents. If a measured current is outside of this range, a potentiostat will turn off the output potential to prevent damaging the unit.

Current ranges

To achieve a consistent level of accuracy and precision for current measurements at both milliamps and nanoamps, current measurements are split into a set of ranges. These ranges are typically separated by an order of magnitude, and whilst one range can usually measure the currents encompassed by the range below it, the accuracy and precision of the measurement will be worse.

Accuracy

The maximum amount that a measured current value can vary from the actual current value (scales with the order of magnitude of the current ranges). It is important to note that most measurements will vary by less than this amount.

Resolution

The smallest change in current that can be measured by a potentiostat. This value scales with the order of magnitude of the current ranges.

Specifications for Voltage Control

Potential (voltage) is the key control parameter of a potentiostat. The range over which it can be swept, along with the precision, accuracy, and resolution of that control, are critical for acquiring meaningful electrochemical data.

Specification

Description

Potential range

The potential window that can be applied and measured by a potentiostat between the working and reference electrodes. This typically applies for both positive and negative potential, and in such a case is represented with a plus/minus symbol.

Potential compliance

The maximum limit for the potential that a potentiostat is capable of outputting between the working and counter electrodes. As with the potential range, it applies for both positive and negative potentials and as such is represented with a plus/minus symbol.

It is important to note the distinction between the potential range and the potential compliance. Potential range is the applied and measured potential between the working and reference electrodes, whilst the potential compliance is the absolute maximum potential that can be applied between the working and counter electrodes.

Accuracy

The maximum amount the output potential of a potentiostat can vary from the set potential (plus/minus offset). Specifically, this refers to the potential between the working and reference electrodes.

Resolution

As a potentiostat uses digital signals to determine the potential to output, any change in potential will appear as a step, and a scan profile a series of steps over time, as shown in figure 4. The applied potential resolution determines how small these steps can be, as it is the smallest change in potential that can be output by a potentiostat.

Software

Easily perform linear sweep and cyclic voltammetry, open circuit potential, and controlled potential electrolysis. The maximum and minimum potentials can be defined along with the number of cycles, the scan rate, and the current range. Simply set the relevant settings and click 'Start', then watch the measurement as it happens with live data plotting.

Software updates are also provided at no extra charge and are available to download from our website.

As with all of our software, data is saved to .csv files so that you can analyze it with your favorite tool. The settings you define are saved alongside your measurement data so that you always have a record of your experimental parameters. Profiles allow you to save commonly used settings configurations so that you can quickly repeat measurements without re-configuring the potentiostat, further speeding up your research.

Software Requirements

| Operating System | Windows 10 (32-bit or 64-bit) |

|---|---|

| CPU | Dual Core 2.5 GHz |

| RAM | 2 GB |

| Available Hard Drive Space | 120 MB |

| Monitor Resolution | 1280 x 960 |

| Communication | USB 2.0 |

Potentiostat Gallery

We're happy with the Ossila Potentiostat. We're currently using it in teaching labs to demonstrate basics of corrosion measurements. It is compact, easy to use, and affordable.

Branislav Dzurnak, Czech Technical University in Prague

Additional Specifications

Standard Electrochemical Cell Glassware (Optional)

Screw-fit PTFE lid with three electrode holes and two gas holes.

Platinum Disk Working Electrode (Optional)

Highly polished platinum embedded in polytetrafluoroethylene (PTFE) plastic bodies.

| Purity | 99.99% |

|---|---|

| Diameter | 2 mm |

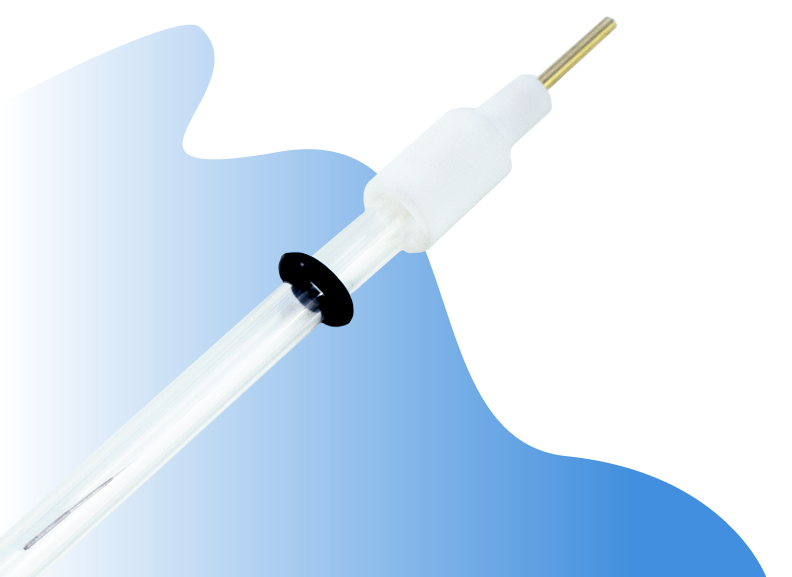

Platinum Wire Counter Electrode (Optional)

| Purity | 99.99% |

|---|---|

| Diameter | 0.5 mm |

Non-aqueous Ag/Ag+ Reference Electrode (Optional)

Aqueous Ag/AgCl Reference Electrode (Optional)

User Manual

Potentiostats in Electrochemistry

Electrochemical techniques such as cyclic voltammetry, linear sweep voltammetry, and other types of voltammetry require a potentiostat to measure redox events taking place in a solution.

A typical electrochemical experimental set up consists of a potentiostat connected to a three-electrode cell via:

- working electrode

- counter electrode

- reference electrode

Potentiostats control the potential between the working and reference electrodes and measure the current between the working and counter electrodes.

Analysis of the data recorded by a potentiostat reveals various intrinsic electrochemical properties of the material, depending which method is used. Using techniques like cyclic voltammetry, potentiostats can be used to find the redox potential of materials, determine the reversibility of a reaction, provide a quantitative description of electrochemical reversibility, and determine the energy levels of semiconducting polymers.

Electrochemical Cell Set-Up

Potentiostats can be used to control two, three or four electrode configurations (and as discussed above, multi-channel bipotentiostats or polypotentiostats can control rotating ring-disk electrode systems).

The three electrode set-up is by far the most common and consists of a working electrode, a counter electrode, and a reference electrode. Each of these three functions also exists in a two electrode cell, only a single interface both provides a reference potential and allows current to flow across the cell. The primary issue with such a set-up is that it renders it impossible to accurately control the potential at the working electrode.

Working electrode

The working electrode is the primary electrode in an electrochemical system. It is where the applied voltage enters the system, and where most electrochemical reactions and electron transfer take place. Measurements of potential and current in an electrochemical system involve the working electrode for both two and three-electrode systems.

Reference electrode

By having a stable, known, and well-defined electrochemical potential, reference electrodes provide a constant for an electrochemical measurement. In an ideal electrochemical system, zero current will flow through the reference electrode, enabling accurate measurements and control of the potential at the working electrode. This is achieved by the reference electrode having a very low impedance, ideally zero.

Counter electrode

Counter electrodes, also known as auxiliary electrodes, complete the circuit of a two or three-electrode system. In two-electrode systems, the counter electrode is also used as the reference electrode. In three-electrode systems, the current is measured between the working and counter electrodes.

In the Box

- Potentiostat

- Shielded cable and crocodile clips

- Test cell chip

- USB-B cable

- 24 VDC power adaptor

- USB Driver with QC test data

Included if purchased with a cell:

- Standard electrochemical cell*

- Platinum disc working electrode*

- Platinum wire counter electrode*

- Non-aqueous Ag/Ag+ or aqueous Ag/AgCl reference electrode*

* Available to be purchased separately

Accessories and Related Products

Resources and Support

How to Perform Cyclic Voltammetry on a Polymer

How to Perform Cyclic Voltammetry on a Polymer

Learn how to perform CV measurements with the Ossila potentiostat.

Read more... Troubleshooting Cyclic Voltammetry and Voltammograms

Troubleshooting Cyclic Voltammetry and Voltammograms

Problems with cyclic voltammetry are often caused by relatively small mistakes. There are several different ways to troubleshoot the issues, depending on the problem.

Read more...