What is a Carbon Nanotube Battery?

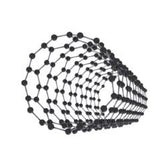

Carbon nanotubes (CNTs), such as single-walled carbon nanotubes (SWCNT), have been tipped as one of the most exciting nanomaterials in the development of battery technology. The key properties of CNTs that make them ideal candidates as battery components is their high electron conductivity, high strength and lightweight nature. Researchers across the globe have explored using CNTs in batteries in a variety of ways.

What makes carbon nanotubes so great for batteries?

Carbon nanotubes are described as graphene sheets rolled up into hollow one-dimensional tubes. Made only of carbon atoms, they have a range of properties that make them ideal for applications in batteries and energy storage:

- High electrical conductivity: CNTs can increase the rate of charge transport in a battery, reducing internal resistance.

- High thermal conductivity: CNTs can improve composite electrode safety by increasing the rate at which heat dissipates throughout the device, avoiding issues like thermal runaway.

- Tunable electrochemical properties: CNTs can be tuned based on their morphology (number of defects, lengths, and diameters)

- High mechanical strength: CNTs can protect battery from structural degradation that results from charge-discharge cycles leading to safer batteries with a longer lifespan.

- High surface area and ability to conduct electrons efficiently: CNTs allow for faster charge transfer, resulting in better energy retention and higher battery capacity.

- Lightweight: Carbon nanotubes are extremely light compared to other conductive materials, which can contribute to reducing the overall weight of energy storage devices. This is beneficial for applications in portable electronics, electric vehicles, and aerospace technologies, where weight is a critical factor.

How are carbon nanotubes used in batteries?

Carbon nanotubes in lithium ion batteries

Lithium-ion batteries continue to dominate the technology industry. However, their basic setup, comprising a simple anode, cathode, and lithium-based electrolyte, is nearing the limits of its capabilities.

To address this, nanomaterials are being introduced to enhance the energy storage capacity and lifespan of lithium-ion cells. A popular example is carbon nanotubes. Their unique one-dimensional structure, along with tunable electronic properties and high strength, makes them an attractive option as either an anode material or a composite material. The advantages they provide include:

- High Li storage capacity without damaging the electrode.

- Faster charge/discharge rates due to shorter ion travel distance.

- Improved electrical conductivity for better performance.

- Larger surface area for better contact with the electrolyte.

- Less volume change during charging and discharging, improving stability.

Anode material in lithium ion batteries

CNTs are attractive anode materials due to their hollow structure provides a large buffer space for lithium ions to flow through. They are also extremely electrically conductive which facilitates the efficient movement of lithium ions and electrons within the anode material. This high Li-ion conductivity accelerates the charging and discharging processes of the battery, improving its power density and rate capability. Defect mean lithium ions can intercalate into CNTs, adsorption into the middle is favored.

Currently commercial anodes are made from graphitic carbon. CNTs offer advantages of higher surface area, better mechanical flexibility and resilience and increased electrical conductivity.

Reinforcing effect of CNTs on the anode

CNTs can also be used in conjunction with anode materials that already have a high performance but need enhancement of other properties like stability. The remarkable mechanical strength and flexibility of CNTs make them ideal for withstanding the repeated stress and strain caused by expansion and contraction during charge and discharge cycles. This is particularly important for materials like silicon-based anodes, which are prone to significant volume changes. CNTs can mitigate cracking and degradation, thereby improving the cycle life of the battery.

CNT conducting agent for the cathode

Conductive agents are used to enhance the electron conductivity of the cathode to increase energy efficiency. Carbon nanotubes have been used as a conductive agent due to it's high electron conductivity and light weight nature. Ozone-treated carbon nanotubes have improved electrochemical performance of cathodes made from high-nickel active materials.

Cutting-edge carbon nanotube battery technology

The energy storage capacity of carbon nanotube ropes (CNT-Polymer composite) can exceed that of advanced lithium ion batteries by a factor of three and mechanical steel springs by four orders of magnitude. This was achieved through the twisting of the rope to create a wind-up torsional spring of SWCNT rope. The concept is similar to how winding up a steel spring stores energy, which is then released when the spring unwinds.

Researchers from Japan also demonstrated the energy storage does not deplete over time and is achievable at temperatures ranging from -60 to 100°C.This a huge advantage over lithium ion batteries, which are famously at risk of catching fire at elevated temperatures. The high tensile strength of the CNT-polymer rope (~ 420 MPa) is one reason for such high mechanical energy storage.

The main application for this CNT battery technology is in biomedicine. CNT-polymer composite rope is thought to be biocompatible (yet to be tested) and therefore could be used in small power-supply devices for artificial organs that require milliwatts of power to function. The researchers predict that the rope could be recharged by body movements, allowing implanted artificial organs to work indefinitely without needing a power source replacement.

Limitations of carbon nanotube batteries

While carbon nanotubes (CNTs) offer significant potential to enhance battery performance, their adoption faces three key technical and commercial hurdles:

- Price - Carbon nanotubes are currently expensive to produce at scale, which limits their commercial viability. Manufacturing high-quality CNTs involves complex and energy-intensive processes such as chemical vapor deposition (CVD) or arc discharge methods. This high production cost translates into expensive battery components, making it challenging for CNT-enhanced batteries to compete with traditional lithium-ion technology in terms of cost.

- Processing - CNTs tend to agglomerate, which can make uniform dispersion difficult during manufacturing. Achieving a homogeneous distribution of CNTs in the anode or cathode is crucial to ensuring consistent battery performance. Furthermore, carbon nanotubes have highly specific structural and electronic properties that need to be carefully controlled during processing.

- Impurities - Impurities from the CNT manufacture such as residual catalyst particles can significantly degrade battery performance. Even small amounts of impurities can negatively affect the electrical conductivity and stability of CNTs. This reduces the overall energy storage capacity and lifespan of the battery. Removing these impurities requires additional steps in the production process, adding to both time and cost!

Single-Walled Carbon Nanotubes (SWCNT)

Learn More

What are Carbon Nanotubes?

What are Carbon Nanotubes?

Carbon nanotubes (CNTs) have been deemed a wonder material due to their remarkable and highly unique physical and chemical properties. They have received much attention over the past decade as a promising material, particularly in the trending field of nanotechnology.

Learn more... Graphene vs Graphite

Graphene vs Graphite

Graphene is a single layer of carbon atoms arranged in a hexagonal pattern, like a sheet of paper. Graphite, on the other hand, is made up of many layers of graphene stacked on top of each other, like a stack of paper.

Read more...

References

- A Review of Nanocarbon-Based Anode Materials for Lithium-Ion..., Nandihalli, N. et al., Crystals (2024)

- Carbon nanotubes in Li-ion batteries: A review, Sehrawat, P. et al., Materials Science and Engineering: B (2016)

- A review of application of carbon nanotubes for..., Casas, C. et al., Journal of Power Sources (2012)

- Ozone-Treated Carbon Nanotube as a Conductive Agent for..., Kim, H. et al., ACS Energy Letters (2023)

- Giant nanomechanical energy storage capacity in twisted single-walled..., Utsumi, S. et al., Journal of Power Sources (2024)

Contributors

Written by

Application Scientist

Diagrams by

Graphic Designer