Evaporation Stack for OFETs, High Density

High Density Evaporation Stack for OFETs

Enabling accurate deposition resolution

Overview | Specifications | Resources

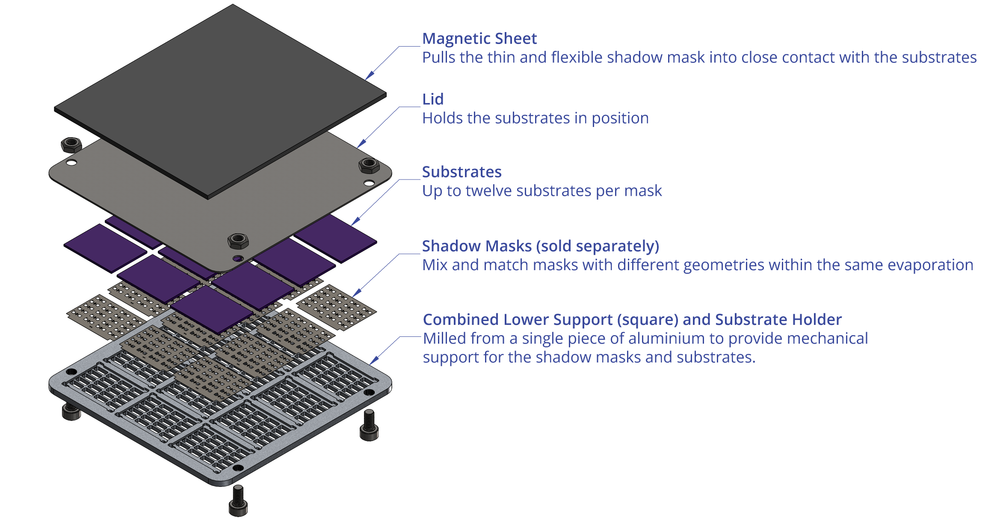

The evaporation stack holds the source-drain shadow masks (sold separately) and substrates in close contact for thermal evaporation. This is crucial for device fabrication because the source-drain channel is the most critical feature on an OFET. For use with the Ossila high-density OFET source-drain evaporation masks and Silicon Oxide Substrates.

Specifications

The key component is the lower support, which is milled from a solid block of aluminum to provide high-precision recesses for individual shadow masks and substrates, and allows mixing-and-matching of shadow masks within a single evaporation.

| Size | 75 mm x 75 mm (2.95" x 2.95") |

| Thickness | 2 mm (exc. bolts) |

| Material | Lower support: milled aluminum Lid: stainless steel Magnetic sheet: vinyl-laminated polymer resin with ferrite powder |

| Substrate capacity | Square design: 12 substrates |

System Overview

Schematic diagrams showing how the high-density FET evaporation masks work together for:

For interdigitated FETs, the source-drain, active area, and gate masks need to be replaced with the corresponding versions.