F8BT (PFBT)

CAS Number 210347-52-7

Materials, OFET & OLED Polymer Materials, Perovskite Interface Materials, Perovskite Materials,F8BT (PFBT), popular green emitting polymer

High purity (>99.9%) and available for priority dispatch

Overview | Specifications | MSDS | Pricing and Options | Literature and Reviews

F8BT (PFBT), CAS number 210347-52-7, a widely used green emitting reference polymer for a variety of applications including as an emissive species in OLEDs [1], an approximately balanced p-type and n-type polymer for OFETs [2] and light emitting transistors [3] as well as being used a polymeric accepter for OPVs [1]. The deep lying HOMO and LUMO levels (5.9 / 3.3 eV) makes it air stable while the liquid-crystalline and beta phases make it widely used for basic research purposes.

Luminosyn™ F8BT (PFBT)

Luminosyn™ F8BT (PFBT) is now available.

High Purity

Purified by Soxhlet extraction with methanol, hexane, and chlorobenzene under an argon atmosphere

Batch-Specific GPC data

Precise molecular weights are always available to provide a reliable reference in your thesis or publication

Large Quantity Orders

Plan and conduct your experiments

with confidence using polymers from the same batch

General Information

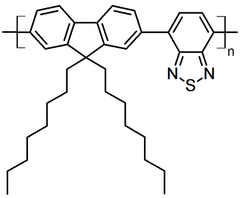

| Full name | Poly(9,9-dioctylfluorene-alt-benzothiadiazole) |

| Synonyms | F8BT, PFBT |

| Chemical formula | (C35H42N2S)n |

| CAS number | 210347-52-7 |

| HOMO / LUMO | HOMO = -5.9 eV, LUMO = -3.3 eV [2] |

| Classification / Family | Polyfluorenes, Benzothiodiazoles, Organic semiconducting materials, Semiconducting polymers, OLED green emitter materials, OLED materials, Organic Photovoltaic materials, Polymer solar cells, OFET materials |

Product Details

| Purity | > 99.9% |

| Appearance | Orange powder/flakes |

Batch details

| Batch number | MW | MN | PDI | Stock info |

|---|---|---|---|---|

| M0231A8 | 298,964 | 78,719 | 3.80 | In stock |

*Recommended processing solvent for M0231A4 is chlorobenzene for its high molecular weights.

Chemical Structure

Device Structure(s)

| Device structure | ITO/PEDOT:PSS AI 4083/TFB/F8BT/F8imBT-Br*/Ca/Al [4] |

| Color |

|

| Max. EQE | 5.1% |

| Max. Current Efficiency | 17.9 cd/A |

| Max. Power Efficiency | 16.6 lm W−1 |

Usage Datasheet

For a high efficiency green OLED we recommend blending F8 (PFO) with F8BT with the below specifications. This ink can then be deposited either in air or in a glove box with little difference in performance, provided that the exposure time and light levels are minimized.

At typical concentrations of 10 mg/ml 100 mg of F8 (PFO) will make around 200 spin-coated devices on Ossila's standard ITO substrates (20 x 15 mm) assuming 50% solution usage (50% loss in filtering and preparation).

OLED reference device:

- F8 with F8BT

- Blend ratio of 19:1 (F8:F8BT) in Toluene

- Total concentration of 10 mg/ml

- 0.45 μm PTFE (hydrophobic) filter

- Spun at 2000 rpm (approx. 70 nm thickness)

Pipetting 20 μl of the above solutions onto a substrate spinning at 2000 rpm should provide a good even coverage with approximately 70 nm thickness. The substrate needs to be spun until dry, which is typically only a few seconds — 15 seconds should be ample to achieve this. Thermal annealing should be undertaken at 80°C for 10 minutes prior to cathode deposition

A basic but efficient OLED can be made using PEDOT:PSS as a hole transport layer and Calcium/Aluminum as the electron contact. When used with the Ossila ITO substrates and shadow masks this produces an easy to fabricate yet efficient >100 cd/m2 device.

Technical Data

| Product Code | Soluble in | Recommended Processing Solvents at 10mg/ml |

| M0231A4 | Chloroform, chlorobenzene | Chlorobenzene |

| M0231A5 | Toluene, chloroform, chlorobenzene | Toluene |

| M0231A6 | Toluene, chloroform, chlorobenzene | Toluene |

| M0231A7 | Toluene, chloroform, chlorobenzene | Toluene |

| M0231A8 | Toluene, chloroform, chlorobenzene | Toluene |

Pricing

| Batch | 250 mg | 500 mg | 1 g |

|---|---|---|---|

| M0231A8 | £330 | £560 | £950 |

| M0231A7 | £210 | £340 | £600 |

MSDS Documentation

Literature and References

Please note that Ossila has no formal connection to any other authors or institutions in these references.

- Conjugated-Polymer Blends for Optoelectronics. C.R. McNeill et al., Advanced Materials, Vol 21, Issue 38-39, 3840 (2009)

- Electron and hole transport in poly(fluorene-benzothiadiazole). Y. Zhang et al., Appl. phys. Lett., Vol 98, 143504 (2011)

- Organic Light Emitting Field Effect Transistors: Advances and Perspectives. F. Cicoira et al., Advanced Functional Materials, Vol 17, Issue 17, 3421-3434 (2007)