The Different Types of Carbon Nanotubes

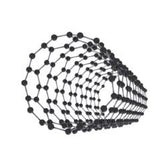

The two main types of carbon nanotubes are single-walled carbon nanotubes (SWCNT) and multi-walled carbon nanotubes (MWCNT). Double-walled carbon nanotubes (DWCNT), with two nanotubes nested in one another, are another type of CNT. Scientific research has led to the development of other types of carbon nanotubes with distinct features. Modifications to the chemistry and structure of carbon nanotubes have improved specific properties for various applications.

List of different types of carbon nanotubes:

- Multi-walled carbon nanotubes (MWCNT)

- Single-walled carbon nanotubes (SWCNT)

- Double-walled carbon nanotubes (DWCNT)

- Functionalized carbon nanotubes

- Short carbon nanotubes

- Aligned carbon nanotubes

- Doped carbon nanotubes

Functionalized Carbon Nanotubes

There are many ways in which to functionalize carbon nanotubes. They fall into the following categories:

Covalent Functionalization: direct attachment to CNT exterior or through linkage groups

Non-covalent Functionalization: attachment to CNT exterior through weaker intermolecular interactions

Encapsulation: Incorporation of metal or fullerene in CNT interior

Each type of CNT functionalization has a variety of methods that fall within the category. A given method of functionalization is used to enhance specific properties of the CNTs. This means the CNTs can be further modified to make them more suited to a specific application. The most popular methods of CNT functionalization are summarized in the table below:

| Functionalization Type | Functionalization Method | Enhanced Property |

|---|---|---|

| Covalent | Fluorination | Solubility in organic solvents |

| 1,3-Dipolar cycloaddition | Solubility in aqueous & organic solvents | |

| Aryl diazonium salt reduction | Solubility in organic solvents | |

| Metal-containing molecular complex formation | Solubility and stability in organic solvents | |

| Carboxylation | Solubility, further functionalization, molecular linker | |

| Hydroxylation | Solubility, further functionalization | |

| Ozonolysis | Further functionalization | |

| Reactive species functionalization | Further functionalization | |

| Electrophilic addition | Further functionalization | |

| Nucleophilic addition | Solubility in water | |

| Radical addition | Solubility in organic and aqueous solutions | |

| Nanoparticle deposition | Solubility in water, interactions with ions | |

|

Non-Covalent |

Surfactant functionalization | Dispersion |

| Polymer wrapping | Dispersion in different solvents | |

| Polymer adsorption | Anchoring of biomolecules, dispersion | |

| Polymer encapsulation | Dispersion | |

| Encapsulation | Metal encapsulation | Magnetism , catalysis , electronic |

| Fullerene encapsulation | Controlled release of cargo |

Covalent functionalization of carbon nanotubes

Strong covalent functionalization offers the widest variety of methods, utilizing well-established functionalization chemistries. It involves the direct attachment of functional groups like halogens or organic molecules, which significantly affect the surface chemistry of CNTs. This has a knock on effect of improving properties like solubility and dispersibility in solvents. Such modifications are critical for solution processing, a process crucial for fabricating electronic devices.

Beyond simple functionalization, certain groups such as carboxylic acids (e.g. MWCNT-COOH) provide reactive sites for further modifications. These can enable attachment of biomolecules via reactions like amidation, enhancing the biocompatibility of CNTs. This makes them suitable for biomedical applications, such as drug delivery or tissue engineering. The versatility and broad range of available chemistries make covalent functionalization a valuable tool for expanding the use of CNTs across various fields.

One drawback of the covalent functionalization of CNTs is that it disturbs the π system of sp2 bonded carbons. New functional groups means that the electronic structure of the cylindrical graphene changes, leading to a reduction in electron conductivity. Depending on the application this is a real issue. For applications requiring high electrical conductivity, other functionalization techniques can be adopted.

Non-covalent functionalization of carbon nanotubes

Non-covalent functionalization approaches are based on CNT interactions adsorbed molecules such as surfactants or polymers. These interactions include:

- van der Waals

- π-π

- CH–π

- electrostatic interactions

Changes in solubility of the surface rely on the surface exposed part of the adsorbed molecules which may by hydrophilic or alter dispersibility in another way. Having charged (ionic) molecules adsorbed to CNTs prevent aggregation as the like charges repel each other. This enables increased dispersibility and avoids issues face which are caused by aggregation.

Encapsulation with Carbon Nanotubes

Encapsulation as a functionalization method is particularly intriguing because the interior of carbon nanotubes are seen as a nanoscale test tubes. They provide a largely unexplored, ultrapure nanoreactor where novel reactions might occur.

The inner surface of CNTs also demonstrates stronger binding energy for adsorbate molecules compared to flat carbon surfaces, which is expected due to the close proximity of the molecules to the curved internal surface of the tube. Additionally, the inner cavity of CNTs provides space for the storage and protection of guest molecules.

Aligned Carbon Nanotubes

Aligned carbon nanotubes (ACNT), such as A-MWCNT, are carbon nanotubes that are arranged in a uniform, ordered direction rather than randomly oriented. This alignment can be horizontal or vertical, depending on how they are synthesized, and it gives them unique properties that make them valuable for various applications.

ACNTs are usually grown from substrate that has a catalyst pinned to it. This process produces long, high-purity nanotubes with sidewalls that are free of catalysts. The alignment of the CNTs means they have enhanced mechanical strength, electrical conductivity, and thermal conductivity due to their uniform structure. This makes them highly efficient for applications in electronics, energy storage, and composite materials. Their ordered arrangement improves performance, durability, and reliability across a range of advanced technologies.

Doped Carbon Nanotubes

Doped carbon nanotubes (CNTs) are CNTs that have been chemically modified by incorporating hetero-atoms, such as nitrogen (N), boron (B), or phosphorus (P), into their carbon lattice. This doping alters the electronic, chemical, and structural properties of CNTs, allowing them to exhibit enhanced electrical conductivity, improved catalytic activity, and increased chemical reactivity. This makes them useful in applications like sensors, batteries, fuel cells, and transistors.

- Nitrogen doping (N-doped CNTs) can increase electrical conductivity and create active sites for catalysis or chemical reactions, making them valuable in energy storage and conversion technologies.

- Boron doping (B-doped CNTs) tends to introduce p-type semiconductor behavior, influencing their use in electronic devices.

- Phosphorus doping (P-doped CNTs) can enhance the electron donor characteristics of CNTs, improving their performance in energy storage applications.

Doping also allows fine-tuning of CNTs' properties for specific applications, such as enhancing their performance in sensors, improving efficiency in fuel cells, or increasing their biocompatibility for biomedical uses.

Short Carbon Nanotubes

Short carbon nanotubes (CNTs) have been show a significant increase in their electronic bandgap as their length decreases. This effect is particularly noticeable when the CNTs are reduced to lengths in the tens of nanometers. Quantum confinement along the length of the nanotube becomes a dominant factor. In shorter CNTs, the motion of electrons is restricted along the length of the nanotube, leading to discrete energy levels and a widening of the bandgap. This effect is crucial for applications in nanoelectronics and optoelectronics, as the bandgap determines the electronic and optical properties of the material. The tunability of the bandgap with CNT length allows for the design of devices with tailored electronic properties, including transistors, sensors, and light-emitting devices.

Shortening CNTs also enhances their gas and ion storage capabilities. Shorter CNTs have a higher surface area-to-volume ratio, exposing more sites for gas molecules or ions to adsorb or be stored. This property is particularly important in applications like energy storage devices (e.g., supercapacitors and batteries), gas storage, and filtration. The increased surface area allows for more efficient ion diffusion and gas adsorption, improving the performance of carbon nanotube-based materials in these applications. The shorter tubes facilitate faster ion or gas transport, which is beneficial for applications requiring rapid charge/discharge cycles or gas uptake and release.

Carbon Nanotubes

Learn More

What's the difference between SWCNT and MWCNT?

What's the difference between SWCNT and MWCNT?

Single-walled carbon nanotubes (SWCNTs) and multi-walled carbon nanotubes (MWCNTs) have some similarities and some key differences. Both materials are made from hexagonal lattices of carbon, specifically graphene sheets rolled up to form tubular structures. However, the nested structure of MWCNTs gives them distinct properties that differentiate them from SWCNTs.

Learn more... How are Carbon Nanotubes Made?

How are Carbon Nanotubes Made?

There are multiple methods for producing carbon nanotubes (CNTs) and they usually involve gas phase processing. The three key methods are; chemical vapor deposition (CVD), laser ablation and arc discharge.

Learn more...

References

- Chemistry of carbon nanotubes in biomedical applications, Wu, H-C. et al., Journal of Materials Chemistry (2010)

- Functionalized carbon nanotubes: synthesis, properties and applications in..., Dubey, R. et al., Nanoscale Advances (2021)

- Nanotube Functionalization: Investigation, Methods and Demonstrated Applications, Kharlamova, M. et al., Materials (2022)

- Encapsulation of single-molecule magnets in carbon nanotubes, Giménez-López, M. et al., Nature Comm. (2011)

- The encapsulation of CdS in carbon nanotubes for..., Cui, X. et al., J. Mater. Chem. A (2014)

Contributors

Written by

Application Scientist

Diagrams by

Graphic Designer