Indium(II) Selenide (InSe) Powder and Crystal

CAS Number 1312-42-1

2D Materials, Low Dimensional Materials, Materials, Post-Transition Metal Chalcogenides (PTMCs),Low price, high purity indium(II) selenide powder and crystals

Suitable for use a semiconductor, photoconductor, and in non-linear optics

Technical Data | MSDS | Structure | Literature and Reviews | Related Products | Resources and Support

Indium(II) selenide (InSe), CAS number 1312-42-1, belongs to the IIIA−VIA family group of 2D layered semiconductors. Each of its layers has a honeycomb lattice made of indium and selenium atoms.

High Purity

High purity ≥99.999% indium(II) selenide Crystal

Worldwide shipping

Quick and reliable shipping

Low price

Low price Indium(II) Selenide (InSe)

Powder & Crystal

Available in Powder & Crystal forms

Like black phosphorus (BP) - but with a much more stable nature under ambient conditions, ultra-thin indium selenide (InSe) offers a useful middle ground between silicon and graphene. Weak van der Waals forces between layers of InSe allow easy mechanical and liquid exfoliation, enabling naturally thin films scaling to true nanometer dimensions. With electron mobility up to 2,000 cm2 V-1 s-1, which is significantly higher than that of silicon and and even higher than few-layer dichalcogenides, and a direct band gap of ~1.3 eV, InSe is a semiconductor comparable to silicon with ultra-fast electron response.

We supply high purity indium(II) selenide powder and crystals. Orders are shipped worldwide.

Indium(II) Selenide Powder

Can be used in electronic and optical devices and in the preparation of InSe nanosheets or nanoparticles by liquid chemical exfoliation or chemical vapor deposition

Available in quantities of 500 mg or 1 g

≥99.995% purity

From £220

Indium(II) Selenide Crystals by Size

Can be used as a semiconductor, in non-linear optics, and to produce 2D monolayer and few-layer InSe by mechanical or liquid exfoliation

Small (≥10 mm2) or medium (≥25 mm2) available*

≥99.999% purity

From £520

*Typical representative size, areas/dimensions may vary.

Technical Data

| CAS Number | 1312-42-1 |

| Chemical Formula | InSe |

| Molecular Weight | 193.78 g/mol |

| Bandgap | 1.3 - 2.0 eV |

| Preparation | Synthetic, by chemical vapor transport (CVT) |

| Structure | Rhombohedral |

| Electronic Properties | 2D semiconductor |

| Melting Point | 600 °C (lit.) |

| Color | Dark brown |

| Synonyms | Indium monoselenide |

| Classification / Family | Transition metal dichalcogenides (TMMCs), 2D semiconductor materials, Nano-electronics, Nano-photonics, Photovoltaic, Materials science |

Product Details

| Form | Purity |

|---|---|

| Powder | ≥99.995% |

| Crystal | ≥99.999% |

Pricing Table

| Product Code | Form | Size/Weight* | Price |

|---|---|---|---|

| M2135C1 | Powder | 500 mg | £220 |

| M2135C1 | Powder | 1 g | £350 |

| M2135A10 | Crystal | Small (≥10 mm2) | £520 ea. |

| M2135A25 | Crystal | Medium (≥25 mm2) | £850 ea. |

*typical representative size, areas/dimensions may vary.

MSDS Documents

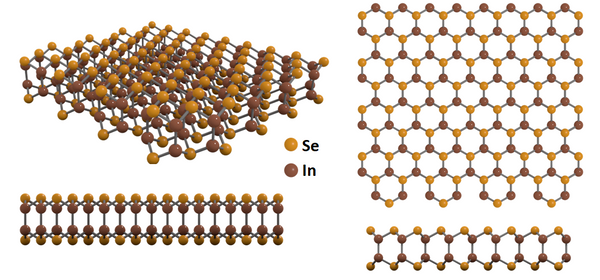

Structure of Indium(II) Selenide

Single layer of indium(II) selenide (InSe) consists of four mono-atomic sheets of hexagonally arranged atoms tetrahedrally linked in the sequence of Se–In–In–Se via covalent bonds. Each of the two indium atoms is bound to three neighbouring selenides. At room temperature under ambient conditions, InSe crystallizes in a rhombohedral layered phase, known as γ-InSe with a space group of R3m.

Each of its layers has a honeycomb lattice made of indium and selenium atoms. The layers are bound by relatively weak van der Waals forces which allow mechanical or wet exfoliation to obtain atomically thin films.

Literature and Reviews

Indium(II) Selenide Powder in Literature

- The direct-to-indirect band gap crossover in two-dimensional van der Waals Indium Selenide crystals,G. W. Mudd et al., Sci. Rep., 6:39619 (2016); DOI: 10.1038/srep39619.

- High Performance and Bendable Few-Layered InSe Photodetectors with Broad Spectral Response, S. Tamalampudi et al., Nano Lett. 2014, 14, 2800−2806 (2014); doi: 10.1021/nl500817g.

- Structural modification and band-gap crossover in indium selenide nanosheets, M. Airo et al., RSC Adv., 6, 40777 (2016); DOI: 10.1039/c6ra00262e.

Indium(II) Selenide Crystals in Literature

- The direct-to-indirect band gap crossover in two-dimensional van der Waals Indium Selenide crystals, G. W. Mudd et al., Sci. Rep., 6:39619 (2016); DOI: 10.1038/srep39619.

- High Performance and Bendable Few-Layered InSe Photodetectors with Broad Spectral Response, S. Tamalampudi et al., Nano Lett. 2014, 14, 2800−2806 (2014); doi: 10.1021/nl500817g.

- Structural modification and band-gap crossover in indium selenide nanosheets, M. Airo et al., RSC Adv., 6, 40777 (2016); DOI: 10.1039/c6ra00262e.

Related Products

We stock a wide range of 2D materials available to purchase online. Please contact us if you cannot find what you are looking for.