Understanding the Basics of Analytical Balances and Microbalances

Laboratory balances have been used for centuries to provide researchers with accurate measurements. There are a wide variety of research areas where the precision measuring of mass is essential. In modern laboratories laboratory scales come in two varieties, analytical balances and microbalances. Both are designed to provide highly accurate mass measurements, however, there are a few major differences between them; in this article we will look into these key differences.

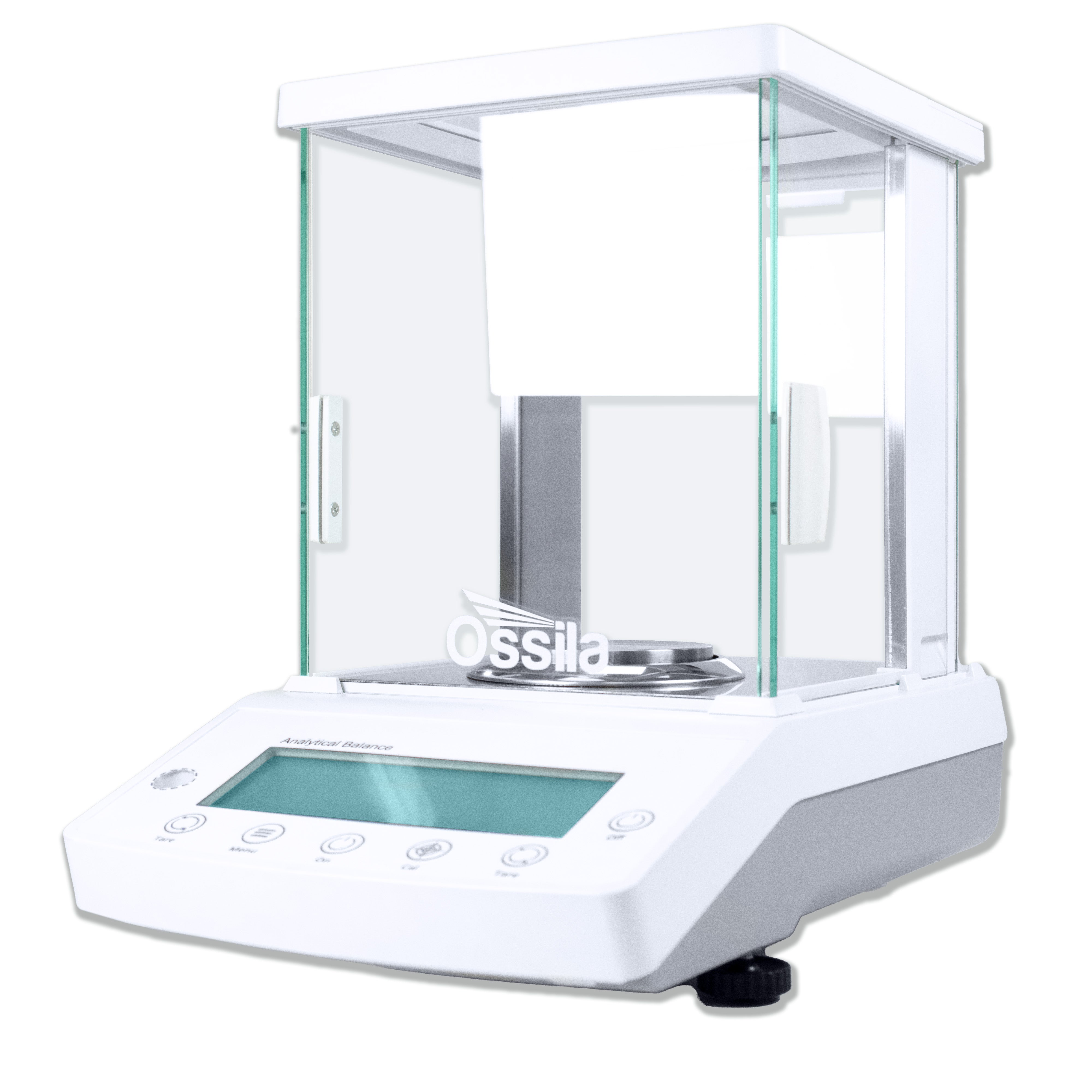

Analytical Balances

Analytical balances are classed as precision weighing instruments that offer readabilities of 1 mg (0.001 g) or better. These balances are common in most chemical, biological, and materials science laboratories. They are used across a wide range of scientific applications including:

- Preparation of samples for chemical analysis techniques

- Development of new formulations

- Quality control processes

- Characterization of materials.

The most important features of any analytical balance are:

- Readability: Also known as the resolution or the minimum displayed value, this is typically either 1 mg (3 d.p. - 0.001 g) or 0.1 mg (4 d.p. - 0.0001 g).

- Maximum Capacity: This is the maximum sample weight that can be placed onto the scale and it usually ranges from 100 g to over 1kg.

- Accuracy and Linearity: The accuracy and linearity are closely related, most scales quote accuracies down to the resolution however the accuracy across the full measurement scale is given by the linearity which can be less.

- Calibration Type: Analytical balances can be equipped with an internal calibration weight allowing for automated frequent calibration of the system. Others may only do external calibration where an external reference must be calibrated against.

- Draft shield: This protects the weighing pan from air currents and environmental disturbances which can impact the accuracy of measurements.

Microbalances

Microbalances are ultra-precise weighing instruments that offer readabilities from at least 0.01 mg (0.000001 g) or better. These balances are designed for applications that require the absolute highest level of accuracy and precision or for weighing incredibly minute samples such as:

- Trace analysis in environmental and forensic studies

- Particulate matter characterization

- Microweighing in research and development

- Determination of filter weights in air quality monitoring

The key features of microbalances include:

- Readability: Typically, 0.01 mg (6 d.p. - 0.000001 g) but may go as low as 0.1 µg (7 d.p. - 0.0000001 g)

- Maximum Capacity: Microbalances have much lower capacity ranging from 1g to 100g.

- Advanced Draft Shield: Often features a multi-layer, motorized draft shield for increased levels of isolation from air currents.

- Vibration Isolation: Built-in or external anti-vibration technology to minimize transmission of vibration from external equipment or people.

- Electrostatic Discharge Protection: Helps with highly static materials and prevents damage to sensitive electronic components and ensures accurate readings.

Factors Impacting Accuracy and Precision

Both types of balances are highly sensitive instruments. The correct setup and usage of them are critical to ensure accurate measurements. There are several factors that can impact your measurements, these include the following:

- Temperature: Fluctuations in temperature can cause air currents and affect the balance's internal components. In addition, calibration of the equipment is done at a set temperature, the behaviour of the electronic systems will vary as a function of temperature and may cause drift from calibration.

- Vibration: External vibrations from equipment, foot traffic, or building movement can disrupt the balance's performance. Systems can come equipped with vibration dampening components such as heavy cast iron bases, or rubber feet. An external anti-vibration table can be purchased. This could be either a heavy granite slab or an air cushioned table.

- Air currents: Drafts from air conditioning, doors, or windows can affect the stability of the weighing pan the placement of the balance away from any of these sources is critical. You should always use the draft shield when weighing samples, and allow enough time for air currents in the chamber to stabilise before taking a reading.

- Static electricity: Samples, containers, or the user's body can carry static charges that interfere with accurate measurements. Use electrostatic discharge protection, such as grounding mats or ionizers, to minimize these effects.

Calibration and Maintenance

Regular calibration and maintenance are crucial for ensuring the long-term accuracy and reliability of analytical balances and microbalances. Follow these best practices:

- Calibrate the balance regularly. If using an externally calibrated instrument use certified weights to guarantee the true mass of the calibration weight.

- Perform routine inspections and cleaning of the balance, including the weighing pan, draft shield, and external components.

- Use the balance in a clean, dust-free environment to prevent contamination of sensitive components.

- Handle weights and samples with care, using tweezers or gloves to avoid contamination and transfer of oils from the skin.

- Schedule professional service and maintenance as needed to keep the balance in optimal condition.

- See Maintenance Tips for Analytical Balances and Microbalances for more detailed information.

Learn More

We used pre-trained AI to help us write this page. As part of our editorial process, our in-house experts review, fact-check, and edit all AI-generated content to make sure we provide you with accurate and helpful information.