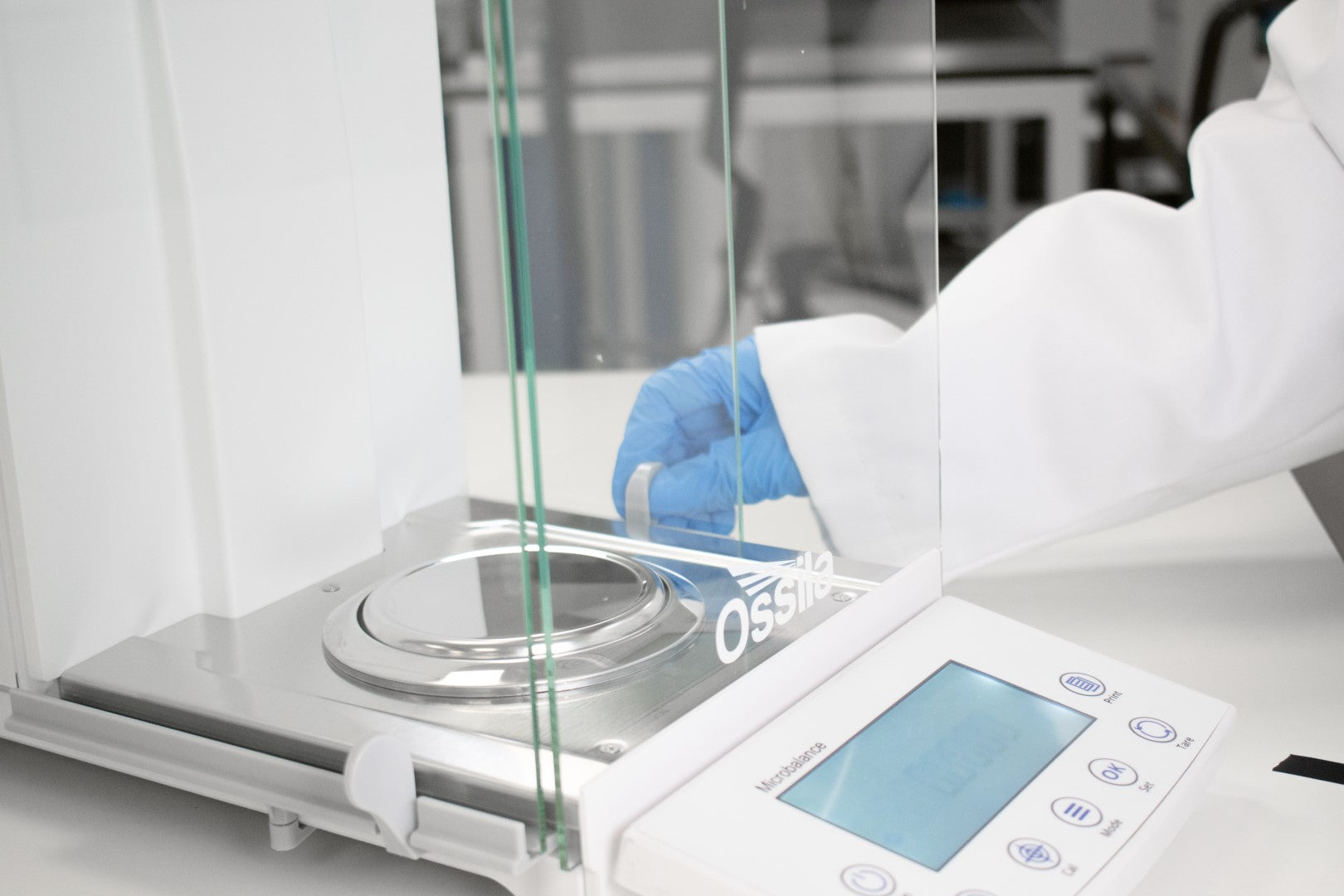

Maintenance Tips for Analytical Balances and Microbalances

Laboratory balances such as an analytical balance or microbalance are precision instruments. To maintain the high levels of accuracy these scales provide a regular maintenance routine is required. Proper care not only helps to maintain the quality of your results but also extends the lifespan of your equipment. To help you make the most of your balances we will provide you with a list of essential weekly, monthly, and yearly maintenance routines you should go through with your balance.

| Daily | Weekly | Monthly |

|---|---|---|

|

Clean inside of weighing chamber Level balance Check calibration Check draft shield |

Thoroughly clean weighing area Check for wear and damage Check and tidy up surroundings |

Check repeatability Check linearity Clean surrounding area |

Daily Maintenance

The first line of defence for your balance is daily maintenance. Daily maintenance needs to be done each time you come to use the balance. The following steps should be done each day:

- Clean the inside of the weighing chamber: Before and after each use, clean the weighing pan and surrounding areas with a soft, lint-free cloth or brush. Remove any spills immediately, this helps to prevent damage to the balance or cross contamination with other samples.

- Levelling your laboratory balance: Check that the balance is level using the built-in bubble level indicator. If necessary, adjust the levelling feet until the bubble is centered.

- Check the calibration: Using certified weights check the calibration of the balance. Simply weigh calibration weights of class E2 or greater to check if the level of accuracy is sufficiently high enough. Check across the full range of sensitivity of the scale from it's maximum load and down. We would recommend a simple quick three-point check of 100g, 1g, and 10mg.

- Check the draft shield: When using the system the draft shield should only be opened for placing samples into, or taking samples out of the balance. Check that the doors can close fully and remember to shut them when you have finished using the balance. Make sure you tare with all draft shields closed to avoid interference.

Weekly Maintenance

On a more long term basis there are few additional maintenance checks that should be done to keep on top of everything, we recommend doing the following on a weekly basis:

- Thoroughly clean the weighing area: Remove the weighing pan and draft shield components, and clean them thoroughly with a mild detergent solution. After cleaning rinse the parts with distilled water to avoid leaving any residue on the scales and allow to dry completely before reassembling.

- Check for wear and damage: Have a quick check over the balance and look for any signs of wear or damage. This could include things such as cracks in the draft shield, loose cables, or faulty connections. Repair or replace any parts as necessary to ensure full functionality of the balance.

- Check and tidy up surroundings: It’s a good idea to check the area around the balance for anything that may’ve changed. Look for new pieces of equipment, doors being wedged open, or any other change that could alter the environment while using your balance. It is also worth tidying up the area surrounding the balance while you do this too.

Monthly Maintenance

Finally, there are a few checks that should be done monthly to test the functionality of the system is as expected and to help make the regular maintenance of the system easier:

- Check the repeatability: You should check to make sure that the balance can provide repeatable results when measuring the same mass value. This can be done by taking a standardized weight and perform multiple measurements noting down the value each time. Check the standard deviation of this measurement across multiple measurements. Make sure this is within the repeatability value stated by the manufacturer.

- Check the linearity: Another important test is a linearity check. Here you measure the accuracy of the balance across the full scales range and can be done in forward and reverse to check for hysteresis. This is done by gradually adding weights starting from a small value going to the maximum capacity and checking the measured value against the actual value of the weight.

- Clean the surrounding area: Thoroughly clean the area around the balance, including the floor and any nearby shelves or equipment. This helps to minimize dust in the surroundings which will keep your balance cleaner for longer.

Other Tips

Even with a regularly maintained balance if the system is used incorrectly then the results obtained will not be accurate. Below are some very simple tips to ensure that the measurements you get each time you weigh a sample are accurate:

- Use the balance in a clean, stable environment.

- Make sure there are minimal temperature fluctuations, air currents, and vibrations.

- Avoid contaminating the samples and vessels.

- Always use clean tweezers and spatulas, and always wear gloves to avoid the transfer of oils.

- When turning the balance on allow the balance to acclimate to the room temperature before weighing.

- Always close the draft shield.

- Don’t overload the balance, keep the total weight below the maximum capacity.

- Make sure to center loads when putting them on the weighing pan.

Microbalance

Learn More

How to Clean Your Analytical Balance and Microbalance

How to Clean Your Analytical Balance and Microbalance

Following this method will prolong the working life of your laboratory balance and keep it weighing as accurately as possible.

Read more... Analytical Balance and Microbalance Calibration

Analytical Balance and Microbalance Calibration

Calibrating of your analytical balance is an important process. It helps to maintain the accuracy and reliability of measurements taken. Regularly checking and undergoing calibration ensures that your balance is outputting accurate and repeatable data.

Read more...We used pre-trained AI to help us write this page. As part of our editorial process, our in-house experts review, fact-check, and edit all AI-generated content to make sure we provide you with accurate and helpful information.