How to Spin Coat to the Very Edge of a Substrate When Using Viscous Solutions

Instructions for Static Dispense Spin Coating Using 45 Degree Angle

- Substrate Preparation:

- Clean your substrates thoroughly using a UV Ozone Cleaner.

- Spin Coating Settings:

- Input your desired spin coating settings on the Spin Coater.

- Substrate Placement:

- Place your prepared substrate into the chuck of the Spin Coater.

- Solution Preparation:

- Fill the pipette with the viscous solution you intend to coat the substrate with.

- Solution Dispensing:

- Dispense the solution onto the substrate by releasing several droplets from the pipette.

- Solution Spreading:

- Use the pipette to spread the solution evenly across the substrate surface.

- Spin Coating Process:

- Close the Spin Coater lid securely.

- Press the start button to initiate the spin cycle.

- Wait for Cycle Completion:

- Allow the Spin Coater to complete its cycle.

- Only open the Spin Coater lid and remove your coated substrate after the cycle has finished.

- Repeat if Necessary:

- If you have additional substrates, repeat the process from Step 3 onward for each one.

Spin Coater

Learn More

The Ultimate Guide to Making Perovskite Solar Cells

The Ultimate Guide to Making Perovskite Solar Cells

Over the past 10 years, perovskite solar cells (PSCs) have achieved record efficiencies of 25.5% single junction solar cells (as of 20211) and these efficiencies are rising impressively.

Read more... Spin Coating: Complete Guide to Theory and Techniques

Spin Coating: Complete Guide to Theory and Techniques

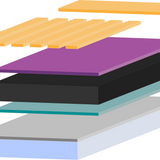

Spin coating is a common technique for applying thin films to substrates. When a solution of a material and a solvent is spun at high speeds, the centripetal force and the surface tension of the liquid together create an even covering.

Read more...