How to Clean Substrates for Photovoltaic or OLED Fabrication

This video provides a walk through guide on how to clean substrates for photovoltaic (such as perovskite solar cells or organic photovoltaics) and OLED fabrication. However, this general cleaning procedure can be applied for other thin film coating processes.

Achieving a clean substrate is an important first step to fabricating good devices as it allows subsequent layers to be kept clean and defect free. All you need for this process is some cleaning fluids, solvents and the Ossila UV Ozone Cleaner.

For effective cleaning of substrates, follow the below steps:

- 5 minute sonication in hot Hellmanex III

- Rinse thoroughly twice in hot de-ionized water

- 5 minute sonication in IPA

- Rinse thoroughly twice in hot de-ionized water

- Dry with N2 gun

- Expose your substrates to a surface treatment techniques, such as UV ozone treatment in a UV ozone cleaner to increase wettability

Get going with fabricating devices

Get started making perovskite, OPV or OLED devices. Contact our technical team for support.

How to Clean Glass Substrates

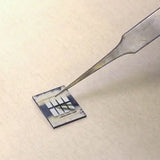

- Carefully remove each substrate from its packaging and load into the substrate holder one by one. Handle the substrates by their sides, being careful not to make contact with ITO covered area.

- Using a gloved hand, gently rub the faces of the substrates using a small amount of Hellmanex. This will help physically remove dirt from the substrates. Rinse this off with generous amounts of water.

- Place the substrate holder into clean glass beaker filled with boiling deionized water and a little Hellmanex solution.

- Place the beaker into an ultrasonic bath filled with boiling deionized water and sonicate for 5 minutes. The ultrasonic bath causes rapid vibration to occur around the substrates, aiding the removal of particulates.

- After 5 minutes sonication, carefully remove the beaker. Take care as the beaker could be hot.

- The substrates should now be dump rinsed twice in boiling deionized water. Use boiling water if possible, to ensure all remaining Hellmanex solution is removed from the substrates.

- The substrates should then be rinsed and sonicated in isopropyl alcohol (IPA) or acetone, or both. For IPA, you can place the substrates into a polypropylene beaker to reduce solvent usage. Be wary of solvent evaporation during sonication. You should sonicate with acetone in a glass beaker. Sonicate the substrates for a further 5-10 minutes.

- The substrates can be kept in solvents until close to deposition time. If you are storing substrates in solvents, keep covered to prevent evaporation.

- Before deposition, hold the substrate with a pair of tweezers and use compressed nitrogen to blow away all the water.

- To increase wettability, expose the substrates to UV ozone treatment. This will significantly increase their wettability, which will help you create smooth, uniform thin films.

Following this rigorous cleaning procedure will give improve your likelihood of creating defect-free films. This is especially important when using wet coating techniques, such as spin coating, dip coating, and slot die coating.

UV Ozone Cleaner

Learn More

OLED Fabrication Guide

OLED Fabrication Guide

In this guide, we demonstrate how to make standard OLED devices in a glove box using materials and equipment easily available to any lab. Find out more.

Read more... Organic Solar Cell Fabrication Guide

Organic Solar Cell Fabrication Guide

This guide demonstrates how to fabricate standard organic solar cells (OSCs) using materials and equipment that are readily available. Find out more.

Read more...