Four-Point Probe User Manual

1. EU Declaration of Conformity (DoC)

We

Company Name: Ossila BV

Postal Address: Biopartner 3 Building, Galileiweg 8

Postcode: 2333 BD Leiden

Country: The Netherlands

Telephone Number: +31 (0)718 081020

Email Address: info@ossila.com

declare that the DoC is issued under our sole responsibility and belongs to the following product:

Product: Four-Point Probe Plus (T2001A5/T2001B5), Four-Point Probe (T2001A4/T2001B4)

Serial Number: T2001A5 - xxxx, T2001B5 - xxxx, T2001A4 - xxxx, T2001B4 - xxxx

Object of Declaration

Four-Point Probe Plus (T2001A5/T2001B5)

Four-Point Probe (T2001A4/T2001B4)

The object of declaration described above is in conformity with the relevant Union harmonization legislation:

EMC Directive 2014/30/EU

RoHS Directive 2011/65/EU

Signed:

Name: Dr James Kingsley

Place: Leiden

Date: 11/11/2024

| Декларация | за съответствие на ЕС |

|---|---|

| Производител | Ossila BV, Biopartner 3 building, Galileiweg 8, 2333 BD Leiden, NL. |

| Декларира с цялата си отговорност, че посоченото оборудване съответства на приложимото законодателство на ЕС за хармонизиране, посочено на предходната(-ите) страница(-и) на настоящия документ. | |

| [Čeština] | Prohlášení o shodě EU |

|---|---|

| Výrobce | Ossila BV, Biopartner 3 building, Galileiweg 8, 2333 BD Leiden, NL. |

| Prohlašujeme na vlastní odpovědnost, že uvedené zařízeni je v souladu s příslušnými harmonizačními předpisy EU uvedenými na předchozích stranách tohoto dokumentu. | |

| [Dansk] | EU-overensstemme lseserklærin g |

|---|---|

| Producent | Ossila BV, Biopartner 3 building, Galileiweg 8, 2333 BD Leiden, NL. |

| Erklærer herved, at vi alene er ansvarlige for, at det nævnte udstyr er i overensstemmelse med den relevante EUharmoniseringslovgivning, der er anført på den/de foregående side(r) i dette dokument. | |

| [Deutsch] | EU-Konformitätserklärung |

|---|---|

| Hersteller | Ossila BV, Biopartner 3 building, Galileiweg 8, 2333 BD Leiden, NL. |

| Wir erklären in alleiniger Verantwortung, dass das aufgeführte Gerät konform mit der relevanten EUHarmonisierungsgesetzgebung auf den vorangegangenen Seiten dieses Dokuments ist. | |

| [Eesti keel] | ELi vastavusavaldus |

|---|---|

| Tootja | Ossila BV, Biopartner 3 building, Galileiweg 8, 2333 BD Leiden, NL. |

| Kinnitame oma ainuvastutusel, et loetletud seadmed on kooskõlas antud dokumendi eelmisel lehelküljel / eelmistel lehekülgedel ära toodud asjaomaste ELi ühtlustamise õigusaktidega. | |

| [Ελληνικά] | Δήλωση πιστότητας ΕΕ |

|---|---|

| Κατασκευαστής | Ossila BV, Biopartner 3 building, Galileiweg 8, 2333 BD Leiden, NL. |

| Δηλώνουμε υπεύθυνα όn ο αναφερόμενος εξοπλισμός συμμορφώνεται με τη σχεnκή νομοθεσία εναρμόνισης της ΕΕ που υπάρχει σnς προηγούμενες σελίδες του παρόντος εγγράφου. | |

| [Español] | Declaración de conformidad UE |

|---|---|

| Fabricante | Ossila BV, Biopartner 3 building, Galileiweg 8, 2333 BD Leiden, NL. |

| Declaramos bajo nuestra única responsabilidad que el siguiente producto se ajusta a la pertinente legislación de armonización de la UE enumerada en las páginas anteriores de este documento. | |

| [Français] | Déclaration de conformité UE |

|---|---|

| Fabricant | Ossila BV, Biopartner 3 building, Galileiweg 8, 2333 BD Leiden, NL. |

| Déclarons sous notre seule responsabilité que le matériel mentionné est conforme à la législation en vigueur de l'UE présentée sur la/les page(s) précédente(s) de ce document. | |

| [Hrvatski] | E.U izjava o sukladnosti |

|---|---|

| Proizvođač | Ossila BV, Biopartner 3 building, Galileiweg 8, 2333 BD Leiden, NL. |

| Izjavljujemo na vlastitu odgovornost da je navedena oprema sukladna s mjerodavnim zakonodavstvom EU-a o usklađivanju koje je navedeno na prethodnoj(nim) stranici(ama) ovoga dokumenta. | |

| [Italiano] | Dichiarazione di conformità UE |

|---|---|

| Produttore | Ossila BV, Biopartner 3 building, Galileiweg 8, 2333 BD Leiden, NL. |

| Si dichiara sotto la propria personale responsabilità che l'apparecchiatura in elenco è conforme alla normativa di armonizzazione UE rilevante indicata nelle pagine precedenti del presente documento. | |

| [Latviešu] | ES atbils tības deklarācija |

|---|---|

| Ražotājs | Ossila BV, Biopartner 3 building, Galileiweg 8, 2333 BD Leiden, NL. |

| Ar pilnu atbilclību paziņojam, ka uzskaitītais aprīkojums atbilst attiecīgajiem ES saskaņošanas tiesību aktiem, kas minēti iepriekšējās šī dokumenta lapās. | |

| [Lietuvių k.] | ES atitikties deklaracija |

|---|---|

| Gamintojas | Ossila BV, Biopartner 3 building, Galileiweg 8, 2333 BD Leiden, NL. |

| atsakingai pareiškia, kad išvardinta įranga atitinka aktualius ES harmonizavimo teisės aktus, nurodytus ankstesniuose šio dokumento | |

| [Magyar] | EU-s megfelelőségi nyilatkozat |

|---|---|

| Gyártó | Ossila BV, Biopartner 3 building, Galileiweg 8, 2333 BD Leiden, NL. |

| Kizárólagos felelösségünk mellett kijelentjük, hogy a felsorolt eszköz megfelel az ezen dokumentum előző oldalán/oldalain található EU-s összehangolt jogszabályok vonatkozó rendelkezéseinek. | |

| [Nederlands] | EU-Conformiteitsverklaring |

|---|---|

| Fabrikant | Ossila BV, Biopartner 3 building, Galileiweg 8, 2333 BD Leiden, NL. |

| Verklaart onder onze uitsluitende verantwoordelijkheid dat de vermelde apparatuur in overeenstemming is met de relevante harmonisatiewetgeving van de EU op de vorige pagina('s) van dit document. | |

| [Norsk] | EU-samsvarserklæ ring |

|---|---|

| Produsent | Ossila BV, Biopartner 3 building, Galileiweg 8, 2333 BD Leiden, NL. |

| Erklærer under vårt eneansvar at utstyret oppført er i overholdelse med relevant EU-harmoniseringslavverk som står på de(n) forrige siden(e) i dette dokumentet. | |

| [Polski] | Deklaracja zgodności Unii Europejskiej |

|---|---|

| Producent | Ossila BV, Biopartner 3 building, Galileiweg 8, 2333 BD Leiden, NL. |

| Oświadczamy na własną odpowiedzialność, że podane urządzenie jest zgodne ze stosownymi przepisami harmonizacyjnymi Unii Europejskiej, które przedstawiono na poprzednich stronach niniejszego dokumentu. | |

| [Por tuguês] | Declaração de Conformidade UE |

|---|---|

| Fabricante | Ossila BV, Biopartner 3 building, Galileiweg 8, 2333 BD Leiden, NL. |

| Declara sob sua exclusiva responsabilidade que o equipamento indicado está em conformidade com a legislação de harmonização relevante da UE mencionada na(s) página(s) anterior(es) deste documento. | |

| [Română] | Declaraţie de conformitate UE |

|---|---|

| Producător | Ossila BV, Biopartner 3 building, Galileiweg 8, 2333 BD Leiden, NL. |

| Declară pe proprie răspundere că echipamentul prezentat este în conformitate cu prevederile legislaţiei UE de armonizare aplicabile prezentate la pagina/paginile anterioare a/ale acestui document. | |

| [Slovensky] | Vyhlásenie o zhode pre EÚ |

|---|---|

| Výrobca | Ossila BV, Biopartner 3 building, Galileiweg 8, 2333 BD Leiden, NL. |

| Na vlastnú zodpovednosť prehlasuje, že uvedené zariadenie je v súlade s príslušnými právnymi predpismi EÚ o harmonizácii uvedenými na predchádzajúcich stranách tohto dokumentu. | |

| [Slovenščina] | Izjava EU o skladnosti |

|---|---|

| Proizvajalec | Ossila BV, Biopartner 3 building, Galileiweg 8, 2333 BD Leiden, NL. |

| s polno odgovornostjo izjavlja, da je navedena oprema skladna z veljavno uskladitveno zakonodajo EU, navedeno na prejšnji strani/prejšnjih straneh tega dokumenta. | |

| [Suomi] | EU-vaatimustenm ukaisuusvakuutus |

|---|---|

| Valmistaja | Ossila BV, Biopartner 3 building, Galileiweg 8, 2333 BD Leiden, NL. |

| Vakuutamme täten olevamme yksin vastuussa siitä, että tässä asiakirjassa luetellut laitteet ovat tämän asiakirjan sivuilla edellisillä sivuilla kuvattujen olennaisten yhdenmukaistamista koskevien EU-säädösten vaatimusten mukaisia. | |

| [Svenska] | EU-försäkran om överensstämmelse |

|---|---|

| Tillverkare | Ossila BV, Biopartner 3 building, Galileiweg 8, 2333 BD Leiden, NL. |

| Vi intygar härmed att den utrustning som förtecknas överensstämmer med relevanta förordningar gällande EUharmonisering som fmns på föregående | |

2. Safety

2.1 Warning

2.2 Use of Equipment

The Ossila Four-Point Probe is designed to be used as instructed. It is intended for use under the following conditions:

- Indoors in a laboratory environment (Pollution Degree 2).

- Altitudes up to 2000m.

- Temperatures of 5°C to 40°C; maximum relative humidity of 80% up to 31°C.

The unit is supplied with a 24 VDC power adapter with a power cord for the country of purchase, in accordance with European Commission regulations and British Standards. Use of any other electrical power cables, adapters, or transformers is not recommended.

2.3 Hazard Icons

The following symbols can be found at points throughout the rest of the manual.

Table 2.1 Hazard warning labels used in this manual.

| Symbol | Associated Hazard |

|---|---|

|

Electrical shock |

2.4 General Hazards

Before installing or operating the Ossila Four-Point Probe there are several health and safety precautions which must be followed and executed to ensure safe installation and operation.

2.5 Power Cord Safety

Emergency power disconnect options: use the power cord as a disconnecting method and remove from wall. To facilitate disconnect, make sure the power outlet for this cord is readily accessible to the operator.

2.6 Servicing

If servicing is required, please return the unit to Ossila Ltd. The warranty will be invalidated if:

- Modification or service has been carried out by anyone other than an Ossila engineer.

- The Unit has been subjected to chemical damage through improper use.

- The Unit has been operated outside the usage parameters stated in the user documentation associated with the Unit.

- The Unit has been rendered inoperable through accident, misuse, contamination, improper maintenance, modification, or other external causes.

2.7 Health and Safety - Servicing

Servicing should only be performed by an Ossila engineer. Any modification or alteration may damage the equipment, cause injury, or death. It will also void your equipment's warranty.

3. Requirements

Table 3.1 details the power requirements for the system, and the minimum computer specifications for the Ossila Sheet Resistance software.

Table 3.1 Four-Point Probe and Sheet Resistance Lite requirements.

| Power | 24 VDC |

|---|---|

| Operating Systems | Windows 10 or 11 (64-bit) |

| CPU | Dual Core 2 GHz |

| RAM | 4 GB |

| Available Hard Disk Space | 269 MB |

| Monitor Resolution | 1440 x 900 |

| Connectivity |

USB 2.0 Ethernet (requires DHCP) |

4. Unpacking

4.1 Packing List

The standard items included with the Ossila Four-Point Probe are:

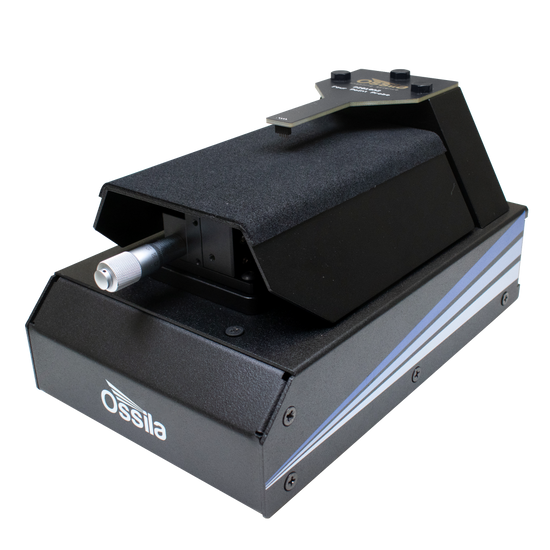

- The Ossila Four-Point Probe.

- 24 VDC power adapter.

- USB-B cable.

- USB memory stick pre-loaded with the user manual, software installer, QC data, and USB drivers.

- 400 - 450 nm FTO coated glass substrate (60 x 60 x 2.2 mm).

- 10 kΩ resistor test head.

4.2 Damage Inspection

Examine the components for evidence of shipping damage. If damage has occurred, please contact Ossila directly for further action. The shipping packaging will come with a shock indicator to show if there has been any mishandling of the package during transportation.

5. Specifications

The Four-Point Probe measurement specifications are shown in Table 5.1 and Table 5.2, and the physical specifications are shown in Table 5.3.

Table 5.1 Four-Point Probe measurement specifications.

| Voltage Range | ±100 μV to ±10 V |

|---|---|

| Current ranges | ±20 µA to ±200 mA (5 ranges) |

| Sheet resistance range | 100 mΩ/square to 10 MΩ/square |

For more information on the current ranges, see our SMU specifications.

Table 5.2 Accuracy and precision of the Four-Point Probe at each resistance range. Accuracy is the maximum deviation from the true value. Precision is the maximum deviation between identical measurements (useful for comparative measurements).

| Sheet Resistance | SMU Accuracy* | Precision | Measured at Range |

|---|---|---|---|

| 100 mΩ/square | ±8% | ±3% | 200 mA |

| 1 Ω/square | ±2% | ±0.5% | 200 mA |

| 10 Ω/square | ±1% | ±0.5% | 200 mA |

| 100 Ω/square | ±1% | ±0.05% | 20 mA |

| 1 kΩ/square | ±1% | ±0.03% | 20 mA |

| 10 kΩ/square | ±1% | ±0.02% | 2 mA |

| 100 kΩ/square | ±2% | ±0.05% | 200 μA |

| 1 MΩ/square | ±8% | ±0.5% | 20 μA |

| 10 MΩ/square | ±30% | ±5% | 20 μA |

* The probe head can introduce up to 4% additional measurement error.

Table 5.3 Four-Point Probe physical specifications.

| Probe Spacing |

Soft-tipped: 1.27 mm Sharp-tipped: 1.6 mm |

|---|---|

| Rectangular Sample Size Range |

Long Edge Minimum: 6 mm Short Edge Maximum: 152.4 mm |

| Circular Sample Size Range (Diameter) | 6 mm to 152.4 mm |

| Maximum Sample Thickness |

Soft-tipped: 8 mm Sharp-tipped: 5 mm |

| Overall Dimensions |

Width: 145 mm Height: 150 mm Depth: 240 mm |

6. Installation

- Connect the 24 VDC power adapter to the power socket on the rear of the unit.

- To control the system using your PC:

- Run the file ‘Ossila-Sheet-Resistance-Lite-Installer-vX-X-X.exe’ on the USB memory stick provided.

- Connect the unit to your PC using the provided USB-B cable, or an Ethernet cable if preferred.

7. Operation

7.1 Taking a Measurement

- Switch the Four-Point Probe on and allow 30 minutes for it to reach a stable temperature.

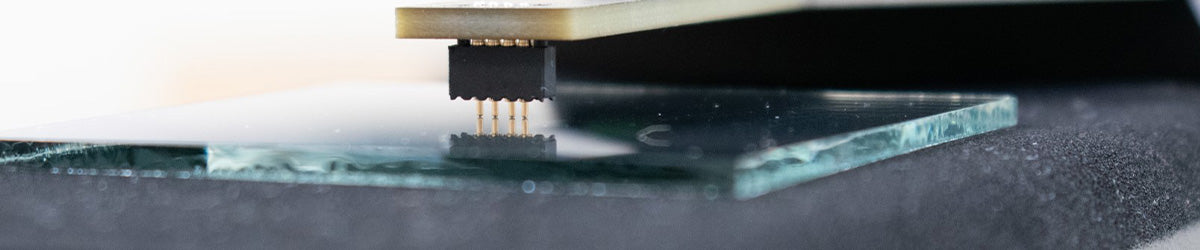

- Place your sample in the center of the vertical stage.

- Raise the platform until the probes have retracted approximately half-way into their housing.

- One full turn of the micrometer (after initial contact is made) is a good way to ensure that there is good electrical contact between the probes and your sample.

- Ensure that the probes make contact with the center of the sample.

- For rectangular samples, the longest edge should be aligned parallel to the probes.

- Then either:

Using the built-in controls (Four-Point Probe Plus only):

- Select Settings on the screen and enter the geometry of your sample (explained in more detail in Section 7.2.2).

- The measurement will start automatically after confirming the settings.

- If a previous measurement on a sample with the same geometry has been performed since powering the system, you can simply select Start.

Using PC control:

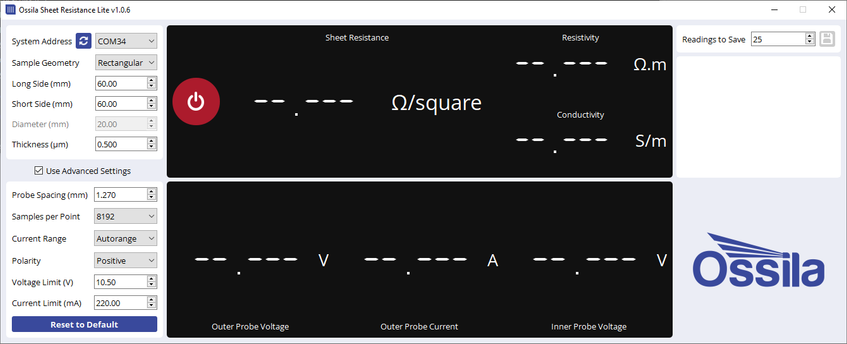

- Start the Ossila Sheet Resistance Lite software. The window shown in Figure 7.1 will open.

- Set the appropriate settings in the software (explained in more detail in Section 7.3).

- Click the on/off toggle button.

When taking a measurement the following steps are performed:

- The system will attempt to pass a current between through the sample.

- If a current can be passed though the sample, the system will measure and display the sheet resistance.

- If a thickness has been provided, the resistivity and conductivity will also be displayed.

- The measurement will continue until it is stopped

7.2 Built-In Controls (Four-Point Probe Plus)

7.2.1 Main Menu

| Start | Start a sheet resistance measurement using the default or previously set sample settings. |

|---|---|

| Settings | Enter the sample geometry settings menus to set the shape, size, and thickness of the sample being measure. |

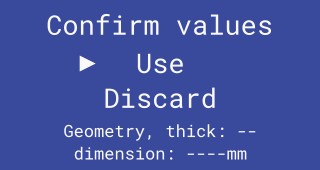

7.2.2 Sample Settings

Sample settings can be accessed either through selecting Settings on the main menu or cycling through to the Sample Settings screen during a measurement.

Press the OK button to change the sample geometry settings.

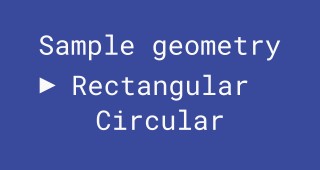

Select the geometry of the sample being measured.

This is required to calculate the geometrical correction factor for the current sample.

If the shape of the sample is irregular, consider whether it is closer to rectangular or circular and then estimate what size of that shape could fit within the sample.

The power on value is rectangular.

Sets the length of the long side of the sample in mm (if the sample is rectangular). The power on value is 60 mm.

Sets the length of the short side of the sample in mm (if the sample is rectangular).

If the value is greater than the long side pressing OK on the last digit will return the cursor to the first digit and reset the value to 0000mm.

The power on value is 60 mm.

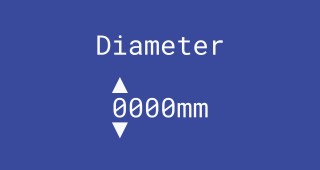

Sets the diameter of the sample in mm (if the sample is circular).

Sets the thickness of the conductive layer being measured in µm.

This enables the calculation of the resistivity and conductivity of the sample, as well as calculating a thickness correction factor for samples with a thickness greater than 40% of the probe spacing.

It is not needed for sheet resistance measurements of samples with a thickness less than 40% of the probe spacing, thus can be set to 0 if not known.

The power on value is 0.45 μm.

Use sets the selected values and starts or restarts a measurement.

Discard returns to the main menu or current measurement without changing the geometry settings.

The new values that have been selected are displayed at the bottom of the screen.

For all size settings (long side, short side, diameter, thickness) the following apply:

- Pressing the up and down buttons changes the value of the current digit.

- Pressing the OK button moves the cursor to the next digit.

- If no value is entered (i.e., 0000mm) pressing OK on the last digit will return the cursor to the first digit.

7.2.3 Probe Type

The soft and sharp probe heads have different probe spacing, so the correct probe type must be selected to ensure correction factors are calculated correctly. To set the probe type, press the up and down together on the loading screen when the Four-Point Probe is powered on (the screen that displays the Ossila logo).

This is only available on firmware version 1.1 or newer.

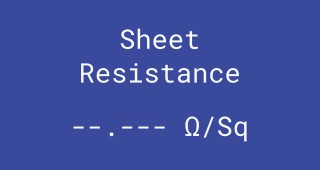

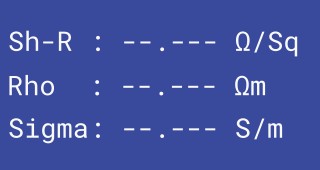

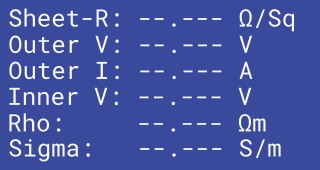

7.2.4 Results

| Sheet Resistance (Sh-R / Sheet R) |

The measured sheet resistance. |

|---|---|

| Rho (Resistivity) |

The calculated resistivity of the sample. Requires a sample thickness to be set. |

| Sigma (Conductivity) |

The calculated conductivity of the sample. Requires a sample thickness to be set. |

| Outer V | The voltage applied between the outer probes. |

| Outer I | The current applied between the outer probes. |

| Inner V | The voltage measured between the inner probes. |

When a measurement is being performed, the following apply:

- Pressing up or down will cycle through results displays.

- Holding down the OK button will stop the measurement.

7.2.5 Updating Firmware

The firmware of the built-in controls can be updated by:

- Download and install the Ossila Firmware Updater software.

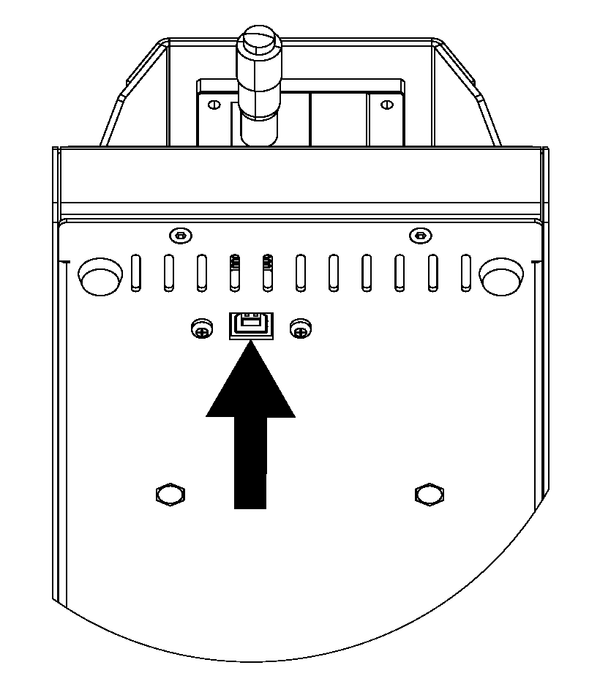

- Connect the USB port on the underside of the unit to the PC (see Figure 7.4).

- Power the system.

- Start the Ossila Firmware Updater software.

- Select the firmware version to install and click Update Firmware.

See the Ossila Firmware Updater User Manual for more information or troubleshooting.

7.3 Sheet Resistance Lite Software

There are several settings in the program which must be filled in before taking a measurement. These are found in the column on the left of the window, as shown in Figure 7.5.

7.3.1 Basic Settings

| System Address | Select the COM port or IP address of the connected unit you intend to use (USB and Ethernet connection

respectively). This box will be populated automatically with the addresses of any units connected to the computer or network. |

|---|---|

| Probe Spacing | Sets the spacing between each of the probes in mm. This is required to determine the appropriate geometric correction factors for the sample being measured. |

| Geometry | Select the geometry of the sample being measured. This is required to calculate the geometrical correction factor for the current sample. If the shape of the sample is irregular, consider whether it is closer to rectangular or circular and then estimate what size of that shape could fit within the sample. |

| Long Side (Rectangular Sample) |

Sets the length of the long side of the sample in mm (if the sample is rectangular). This is required for calculating the appropriate geometrical correction factor. |

| Short Side (Rectangular Sample) |

Sets the length of the short side of the sample in mm (if the sample is rectangular). This is required for calculating the appropriate geometrical correction factor. |

| Diameter (Circular Sample) |

Sets the diameter of the sample in mm (if the sample is circular). This is required for calculating the appropriate geometrical correction factor. |

| Thickness (Optional) |

Sets the thickness of the conductive layer being measured in µm. This enables the calculation of the resistivity and conductivity of the sample, as well as calculating a thickness correction factor for samples with a thickness greater than 40% of the probe spacing. It is not needed for sheet resistance measurements of samples with a thickness less than 40% of the probe spacing, thus can be set to 0 if not known. |

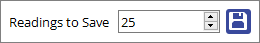

7.2.2 Saving Results

| Readings to Save | Set the number of measurements to save. |

|---|---|

| Opens a file dialog window to choose where to save the data. When the file is chosen, the selected number of readings will be taken and saved to the file. |

|

| Saved Data Format | The applied current, measured voltage, and measured sheet resistance are saved to the file. The mean and

standard deviation of the sheet resistance measurements are saved to the same file, placed after the

data readings. If a thickness is provided, the resistivity and conductivity values are also saved. |

7.2.3 Advanced Settings

Advanced settings can be found by checking the “Use Advanced Settings” box below the basic settings. This will also show the voltage and current set between the outer probes, and voltage measurements between the inner probes. Note that these settings will only be used whilst “Use Advanced Settings” box is ticked, default settings will be used when not ticked.

| Samples per Point | Select the number of samples to be taken for each measurement. A higher number of samples per point will improve the accuracy and precision of the measurement. However, this will increase the time taken for it to be performed. |

|---|---|

| Current Range | Select whether the appropriate range should be automatically determined or whether a specific range of

currents is used. This defines the upper limit and accuracy of current measurements that can be performed by the unit. Autorange will enable the measurement to automatically switch ranges as needed. The maximum current values for each range are shown in the range selection box. |

| Polarity | Sets whether the measurement polarity is positive or negative. |

| Voltage Limit | Sets the maximum voltage the measurement can apply to the sample in volts. If the voltage limit is exceeded the measurement will stop. |

| Current Limit | Sets the maximum current the measurement can apply to the sample in mA. If the current limit is exceeded the measurement will stop. |

| Reset to Default | Clicking this button will reset all advanced settings to their default values. |

Testing the System

8.1 Test Head

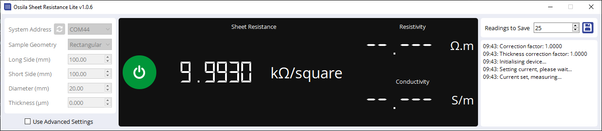

The Four-Point Probe is shipped with a test head that can be used to verify the correct operation the system by providing a reference measurement. It is designed to give a response of 10 kΩ when a sheet resistance measurement is performed on it using the system.

8.1.1 Taking a Measurement

- Replace the four-point probe head on the system with the test head.

- Remove the 3 screws attaching the head to the system.

- Lift the probe head and unscrew the cables from the underside.

- Remove the four-point probe head.

- Attach the cables to the underside of test head.

- Fasten the test head to the unit using the 3 screws.

- Plug in and switch on the system or restart it if already on.

- Allow at least 30 minutes for the system to warm up.

- Enter the settings in Table 8.1 into either the built-in controls or the Sheet Resistance Lite software.

- Start the measurement.

- The system should measure a sheet resistance between 9.9 and 10.1 kΩ/square (within 1% of 10 kΩ/square).

Table 8.1 Measurement settings for the test head.

| Setting | Value |

|---|---|

| Probe Spacing | Either probe type; Any value less than 1.6 mm |

| Sample Geometry | Rectangular |

| Long Side | Any value greater than 100 mm |

| Short Side | Any value greater than 100 mm |

| Thickness | 0 μm |

8.2 FTO Coated Glass

The system is supplied with an FTO coated glass substrate that has been measured using the Four-Point Probe. It can be used to verify the correct operation of the probe head. The measured data is provided on the USB drive for reference. Please note, the FTO coating is only on one side of the glass substrate.

Taking a Measurement

- Plug in and switch on the Four-Point Probe or restart it if already on.

- Allow at least 30 minutes for the system to warm up.

- Place the FTO coated glass substrate on the sample stage, centered beneath the probes.

- Raise the platform until the probes have retracted approximately half-way into their housing.

- Start the Sheet Resistance Lite software and enter the settings in Figure 8.3.

- Enter the settings in Table 8.2 into either the built-in controls or the Sheet Resistance Lite software.

- See Section 7.2.3 for how to change the probe type for the built-in controls.

- Start the measurement.

- If the measurement fails, try flipping the substrate and measuring the other side.

- Compare the measured sheet resistance values to those in the “sheet-resistance.csv” file on the USB drive in the “FTO Test Data” folder.

Table 8.2 Measurement settings for the FTO coated glass.

| Setting | Value |

|---|---|

| Probe Spacing | Soft-tipped probes: 1.27 mm Sharp-tipped probes: 1.6 mm |

| Sample Geometry | Rectangular |

| Long Side | 60 mm |

| Short Side | 60 mm |

| Thickness | 0.425 μm |

9. Troubleshooting

Most of the issues that may arise will be detailed here. However, if you encounter any issues that are not detailed here, then please contact Ossila.

9.1 Installation and Setup

| Problem | Possible Cause | Action |

|---|---|---|

| No power/display | The power supply may not be connected properly. | Ensure the system is firmly plugged into the power supply, and that the plug is connected to both the adapter and a working power socket. |

| The power supply adapter has a fault. | Contact Ossila for a replacement power supply adapter. | |

| Software does not start | The wrong version of Windows is installed on the computer. | Install the software on a computer with Windows Vista or newer. |

| The software has not installed properly. | Try reinstalling the software. | |

| Cannot connect to the system via USB | The USB cable may not be connected properly. | Ensure the USB cable is firmly plugged in at both ends. |

| The USB cable may not be connected to a working USB port. | Try connecting the unit to a different USB port on the computer. | |

| The USB cable is defective. | Try using a different USB-B cable, and contact Ossila if necessary. | |

| Cannot connect to the system via network | The MAC address of the unit is not registered with the internal network. | Register the system on the network using the MAC address obtained via a USB connection (see Source Measure Unit manual). |

| The Ethernet cable may not be connected properly. | Ensure the Ethernet cable is firmly plugged in at both ends. | |

| The Ethernet cable is defective. | Try using a different Ethernet cable. |

9.2 Error Messages and Warnings

| Message | Description |

|---|---|

| Current limit exceeded | The measured current is greater than the set current limit. |

| Voltage limit exceeded | The output voltage is greater than the set voltage limit. |

| Unable to measure sample, resistance outside of measurable range | The system is unable to pass a current through the sample under test. |

| Long edge must be able to fit all probes | The long edge of a rectangular sample is shorter than 3 times the probes spacing. |

| Diameter must be able to fit all probes | The diameter of a circular samples is shorter than 3 times the probes spacing. |

| Short edge cannot be longer than the long edge | The short edge is greater than the long edge for a rectangular sample. |

| Sample removed, stopping measurement | The system has detected that the sample has been removed. |

| Error communicating with system | The software is unable to connect to the system. |

| Unable to open file: permission was denied | The software does not have the necessary permissions to access the given file path, or the file is already open in other software. |

| Unable to save file: permission was denied | The software does not have the necessary permissions to access the given file path, or the file is already open in other software. |