Choosing the Right Spin Coater Chuck

A well-designed and correctly chosen chuck provides stability and balance during the spin coating process. It needs to be able to withstand the rotational forces of a spin coater and also to maintain the substrate firmly in place without any signs of wobbling or vibration, helping to ensure consistent results. For this reason, it is important to choose (or design) the right chuck for your spin coater.

Spin Coater Chucks

Substrate Holder

The chuck size generally refers size of substrate holder (the recess in the spin coater chuck) which holds the samples in place while spinning. This determines the maximum sample size that can be accommodated by the spin coater. By varying the depth of the recesses, you can have multiple substrate holders on one chuck.

For example, this diagram shows the Ossila E461 Standard Chuck. Here you can see there is an upper and a lower recess, which are capable of holding substrates of different sizes.

- The upper recess is cut 1 mm deep into the chuck with a substrate size of 50 x 50 mm.

- The lower recess is cut 2 mm deep into the chuck with a substrate size of 20 x 15 mm.

If the substrate you are using is smaller than the chuck size, it should be close to the same size so that the recess can securely hold the sample during a high-speed acceleration.

Diameter of The Chuck

Chuck size can also refer to the diameter of the chuck as a whole. Chuck diameter is important for determining chuck compatibility with other attachments or components of the spin coater. For example, you may require additional accessories for sample mounting and handling. These accessories need to be compatible with the spin coater chuck.

Standard Chuck Sizes

The maximum diameter of Ossila Spin Coater Chucks is 85 mm, with a max subtrate depth of 2.5 mm and max subtrate width of 55 mm. Chucks for the Ossila Spin Coater have three standard sizes with different substrate recess sizes:

- Upper Recess: 50 mm x 50 mm. Lower Recess: 20 mm x 15 mm

- Upper Recess: 2 inch x 2 inch. Lower Recess: 1 inch x 1 inch

- Upper Recess: 76 mm x 26 mm (for microscope slides). Lower Recess: 20 mm x 15 mm (which fits our standard substrates)

Changing the our chucks is quick and easy, so one spin coater can accommodate many different chuck sizes, coating many different samples.

The Ossila Spin Coater also has a magnetic safety switch that stops the chuck from spinning when the lid is open. The customizable recess in the chuck allows hthe user to use their own substrate system.

Spin Coater

Custom Chuck Design for the Ossila Spin Coater

Getting the precise recess for your substrate can be very important. They ensure the substrate remains centered and fixed during spinning, reducing the likelihood of uneven or non-uniform coating thicknesses. A precise chuck recess also acts as a containment area for the coating solution. When the spin coater is being operated at high speeds, the recessed area helps to contain the solution, preventing excessive spillage or overflow.

At Ossila, you can design custom chucks that are compatible with our spin coater and can be perfectly suited to your substrates.

Material

Firstly, you need to choose your chuck material: polypropylene (PP) or polytetrafluoroethylene (PTFE). Polypropylene will be suitable for the majority of coating materials. However, PTFE has improved chemical resistance properties, can withstand higher temperatures and is slightly easier to clean. You should check if your solution is compatible with PP and PTFE before making this decision.

Recess Shape and Dimensions

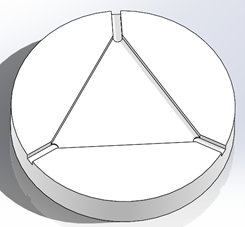

When designing a custom spin coater chuck, you must define your recess shape. The most common shapes for chuck recesses are circular, square or rectangular. However, we can accomodate different shapes to suit your specific substrates. For example, see the below diagram of a chuck designed with a triangular recess.

Spin coater chucks can also feature multiple recesses of various sizes on the same chuck (as in the above image). These chucks can accomodate samples of various shapes and sizes. For example, a spin coater chuck could have a circular recess for a circular substrate, whilst also having a rectangular recess for rectangular substrates.

As well as recess shape, you need to define the dimensions and depth of each substrate recess. At Ossila, the maximum diameter of the chuck is 85 mm, maximum depth is 2.5 mm and maximum width is 55 mm.

If you require a chuck with very specific dimensions or shapes, you can send our team a CAD file with your specific designs (.STL file for AutoCAD /TurboCAD, .SLDPRT file for SolidWorks). Alternatively, if it is a simple design (e.g. two rectangular recesses), you can simply send the dimension of both recesses to our team (L x W x D).

For example, "spin coating chuck with two rectangular recesses. One recess with dimensions 25 mm x 25 mm x 1 mm and one recess 20 mm x 15 mm x 2 mm".

Do I Need a Vacuum Chuck?

Some spin coaters use vacuum chucks to hold your substrates in place, Vacuum chucks are incredibly useful for holding large substrates in place, for example whole silicon wafers.

However, integrating a vacuum into a spin coater adds complexity and limitations to your equipment. The main problems with using vacuum spin coaters are:

- Vacuum chucks require additional components such as vacuum pumps, valves and controls in order to function.

- Maintaining the vacuum pump requires additional maintenance.

- Vacuum lines can become easily contaminated with solvents or coating solutions, drastically reducing the vacuum pumps lifetime.

- Increases the overall cost of the spin coater and its maintenance requirements if the vacuum was to become damaged.

- Not all substrates or coating materials are compatible with vacuum-assisted spin coating.

- Some materials may be sensitive to the vacuum environment or may require specific gas atmospheres rather than a vacuum.

- Porous substrates or non flat substrates will compromised the vacuum, and will not be sufficiently held down by the vacuum.

- Thin substrates can be warped by exposure to vacuum, affecting the subsequent film

We've tackled these problems by designing a spin coater which doesn't require a vacuum to hold your substrate in place. The Ossila Spin Coater uses chucks made with recesses to firmly grip the substrates while letting extra ink flow off during spinning. This helps reduce warping and improves the quality of the film.

This can potentially reduce the need to repair and maintain an additional part of the spin coater, so less chance research is going to be disrupted by unexpected equipment failure.

Spin Coater