Microstepping Technology in Syringe Pumps

A syringe pump is a critical tool in a wide variety of research fields, ranging from chemical analysis to drug development. However, the need for even greater precision and accuracy has resulted in the implementation of advanced controller technology. Microstepping technology has massively improved syringe pump performance and reliability.

What Is Microstepping?

Microstepping is a technique used when controlling the motion of stepper motor, it allows for an increased resolution compared to standard full-step operation. When full-stepping, the stepper motor rotates in fixed increments, typically 1.8° per step or 200 steps per revolution. When microstepping, these full steps are divided into much smaller increments.

In a stepper motor electrical windings are energized (have a current applied) in pairs. These act as electromagnets attracting the magnetic rotor and causing it to move to align with these windings. By energizing these pairs in sequence the motor can rotate.

On the other hand, microstepping involves energizing two pairs simultaneously. Each pair is energized with varying currents. This results in the motor shaft being rotated to an intermediate position. By precisely controlling the current in each winding the motor driver can achieve fractional steps, resulting in increased resolution and smoother motion.

By employing microstepping, syringe pumps can achieve a higher degree of resolution and accuracy in fluid delivery. The level of microstepping achieved is typically quoted as a fractional value, 1/16, 1/32, and 1/64 are common levels of microstepping. This means that each full step can be broken down into these fractional values. Some controllers are even capable of achieving as low as 1/256 microstepping. This means for a 200 steps per revolution motor a full revolution could consist of 51,200 individual microsteps.

Ossila syringe pumps can acheive a level of microstepping of 1/128. This means that each of the 200 steps which make up each revolution of the lead screw which drives the syringe, can be split into 25600 smaller steps. This is also great for smooth fluid dispension and can reduce flow rate fluctuation.

Why Do I Need Microstepping in Syringe Pumps?

- Microstepping drastically reduces the amount of fluid that can be delivered in a single pulse of a motor. This means that microstepping allows syringe pumps to deliver fluids with a high level of accuracy.

- By delivering smaller volumes of fluid, microstepping syringe pumps can provide smoother flow of fluids. This reduces flow rate fluctuation.

- The force used to move a microstep is significantly lower that a full step, microstepping helps minimize the vibration and noise generated by the stepper motor when a motor movement occurs.

What Are the Issues with Microstepping?

There are some drawbacks of incorporating microstepping into a syringe pump:

- When microstepping is incorperated, the available torque decreases. Only during full steps is the maximum torque output possible. By chopping up the full step into a series of smaller steps you effectively portion out the available torque for each microstep.

- To perform microstepping the driver electronics need to be more complex and additional components are needed. Higher levels of microstepping will also require higher quality more expensive components.

Applications of Microstepping Syringe Pumps

- Microfluidic systems often require precise control over small volumes of fluids. Typically, in microfluidic experiments the volume the range can be anywhere between microliters and picolitres. Syringe pumps with high levels of microstepping can deliver these minute volumes. This has allowed researchers to perform complex microfluidic experiments, such as droplet generation, flow focusing, and gradient formation.

- High-performance liquid chromatography (HPLC) relies upon a stable and accurate flow of sample and carrier solvent. Microstepping enabled syringe pumps provide the necessary flow precision and stability, minimizing pulsation and ensuring consistent mobile phase delivery, even at low flow rates.

- In vitro cell culture studies often require continuous and controlled perfusion of media and nutrients. Syringe pumps with microstepping can deliver smooth and pulse-free flow, mimicking in vivo conditions and supporting the growth and maintenance of cells in microfluidic devices or bioreactors.

Incorporating microstepping technology into syringe pumps greatly increases the precision and accuracy of these instruments. We have chosen to incorporate microstepping technology in our syringe pumps to allow users maximum control over their depositions, and to reduce flow rate fluctuations as much as possible.

Syringe Pump

Learn More

How do Syringe Pumps Work?

How do Syringe Pumps Work?

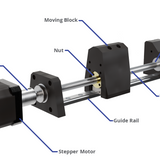

Syringe pumps are electromechanical devices that are designed to convert rotational motion into linear motion.

Read more... How To Set Up and Use The Ossila Syringe Pump

How To Set Up and Use The Ossila Syringe Pump

The Ossila Single Syringe Pump and Ossila Dual Syringe Pump are quick and easy to set up and use. Both models have similar internal circuitry, in-built software, and controls.

Read more...We used pre-trained AI to help us write this page. As part of our editorial process, our in-house experts review, fact-check, and edit all AI-generated content to make sure we provide you with accurate and helpful information.