Optical Fiber Spectroscopy

Optical fibers (or fiber optic cables) are cables which transmit light efficiently along an extremely thin glass (silica) or plastic fiber. Light travels down the cable due to total internal reflection. There is relatively low loss of signal over large distances at specific wavelengths. Optical fibers are often used in telecommunications or data communication. However, they can also be useful in spectroscopy as they can transfer light efficiently between modular spectroscopy elements with little attenuation.

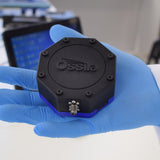

Using optical fibers can help you ensure that the maximum amount of light reaches your sample. They are also reduce alignment issues when setting up your spectrometer and can act as a waveguide for signal emitted or transmitted by your sample. In many cases, using optical fibers can also significantly improve your signal-to-noise ratio. This is especially important if you are using a modular spectrometer like the Ossila USB Spectrometer. It's for this reason that these compact, modular spectrometers are sometimes referred to as fiber optic spectrometers.

What are Optical Fibers?

Optical fibers consist of a thin glass fiber core, surrounded by some protective cladding and a final protective coating. This thin core is usually made of silica glass with a diameter between 50 - 1000 µm, but it can sometimes be made of a polymer material, such as PMMA.

This glass fiber core is then surrounded by cladding which has a slightly higher refractive index than the core. This difference can be as subtle as a 1% difference; however, in refractive index it will determine the critical angle θC. This angle θC is the angle of incidence where the light will be refracted at 90° to the surface normal and is defined with the following equation:

For optical fibers, the critical angle is determined at the boundary between the core (with a refractive index, n2) and the cladding (with a refractive index, n1). If the angle of incidence is larger than this critical angle compared to the normal, then the light will be totally internally reflected - and therefore transmitted down the cable.

Another important factor to consider when using optical fibers is the acceptance angle of the cable, α. This angle defines the "cone" of acceptance of the fiber. In other words, this is the maximum angle through which light can enter into the optical fiber and be totally internally reflected at the core-cladding boundary. If the entrance angle is greater than this acceptance angle, then θ < θC and the light will escape the fiber.

Optical Fiber Attenuation

Attenuation is a measure of how much light is lost during its transmission through an optical fiber. When light enters the fiber, it is transmitted down the cable by total internal reflection. At certain wavelengths, these fibers can guide this signal down the fiber with extremely low levels of attenuation (or loss of light signal). Attenuation in an optical fiber is defined using this equation:

Where Px is the power at a distance x, down the cable and P0 is the power in the fiber when x=0. In high quality optical fibers and at the right wavelength, this attenuation is over measured over very large distances (kilometers). Attenuation can be approximately related to transmission of light as shown in the table below.

| Attenuation (dB) | Transmission (%) |

| 0.01 | 99.8 |

| 0.1 | 98 |

| 0.5 | 89 |

| 1 | 79 |

| 2 | 63 |

| 3 | 50 |

| 5 | 32 |

| 10 | 10 |

The graph above shows the attenuation curve for the Ossila Optical Fiber. You can see here that this fiber has decent optical transmission below 400 nm (T>80%) and very good optical transmission between 400 nm and 1100 nm (T>98%). This should help you waveguide light between modular spectroscopy components, increasing signal and reducing noise.

When to use Optical Fibers in Spectroscopy

Using optical fibers can help you capture and waveguide emitted light efficiently. As you can see in the above graph, the signal intensity (and therefore signal-to-noise ratio) is greatly improved by using optical cables between modular components of the spectrometer. Fluorescence measurements are emitted in all directions equally and is therefore not a collimated emission. Optical fibers help direct these photons to the spectrometer, and you therefore achieve a better signal to noise ratio.

However, when taking absorbance measurements of thick, dark films — for example with photovoltaic materials — transmission levels through the film will be quite low. For example, a measurement of 1.0 A.U. means that 10% of the light source is transmitted through the sample and measured. If there is any loss of signal through the optical fiber this will decrease the size of your absorbance signal significantly.

Optical fibers will transmit visible light less efficiently, so there may be a loss of signal when measuring absorbance through optical fibers, especially due to the increased distance traveled. Therefore, measuring absorbance through optical fibers will only decrease the signal-to-noise ratio and may lead to a noisier measurement. Therefore, when measuring transmission or absorbance on thick or dark films, we recommend measuring without optical cables. When taking measurements through air, be sure to place the components as close as possible towards one another or use appropriate optics to direct this transmitted light to the spectrometer.

Losses in Optical Fibers

There are several sources of loss in optical fibers, such as absorption of light within the cable, cable bending, connector losses, etc. You may notice attenuation through an optical fiber if there are intrinsic issues with the cable. Intrinsic faults fall into three categories: absorption, dispersion and scattering.

Absorption accounts for the light that is absorbed by the materials within the fiber. The largest causes of absorption in optical fibers are residual OH+ ions within the silica or from dopants which are used to alter the refractive index of the glass or cladding. Attenuation due to absorption will increase with increasing cable length.

Dispersion refers to the distortion a signal experiences as it travels through an optical fiber. For example, if you start with a laser light source of narrow band width, the broadening of this signal after transmission through the optical fiber is the dispersion of the signal. Scattering losses can also occur in an optical fiber occur because of defects or density fluctuations in the cable. Scattering losses are wavelength dependent. Therefore, at higher wavelengths there is less attenuation due to scattering.

Bending is the one of the most common issues that arises when using optical fibers. Micro bending relates to very small distortions in the walls of the cable or the cladding of an optical fiber. Macro bending however is when the arrangement of your optical components means that θ < θC and light escapes the fiber. Improper handling of the optical cable can result in bending issues.

Attenuation is lowest in silica optical fibers in the IR region. In fact, the minimum attenuation within silica optical fibers is at around 1550 nm. Therefore, IR signals are used for transmitting informational signals over longer distances. Using optical fibers can be very useful in setting up modular fiber optic spectrometer. However, bear in mind that there can be attenuation in the visible light region.

USB Spectrometer

Read More

An optical spectrometer is an essential instrument used for conducting any optical material research, as it allows you to quickly and easily characterize your samples. Spectrometers are powerful tools, and they work by measuring properties of light (such as wavelength and intensity) as it is received through your material. When choosing an optical spectrometer, it is important that you consider the specific needs of your project as well as the overall objectives of your research.

Read more... Negative Absorbance: Can Absorbance Ever Be Negative?

Negative Absorbance: Can Absorbance Ever Be Negative?

In general, you should not measure negative absorbance values for any sample. This in unphysical. Absorbance measurements come from transmission measurements where light that passes through your sample is collected by a measurement system, such as an optical spectrometer. This measured light is then compared to a reference spectrum.

Read more...