Contact Angle Goniometer Applications

What is a contact angle goniometer?

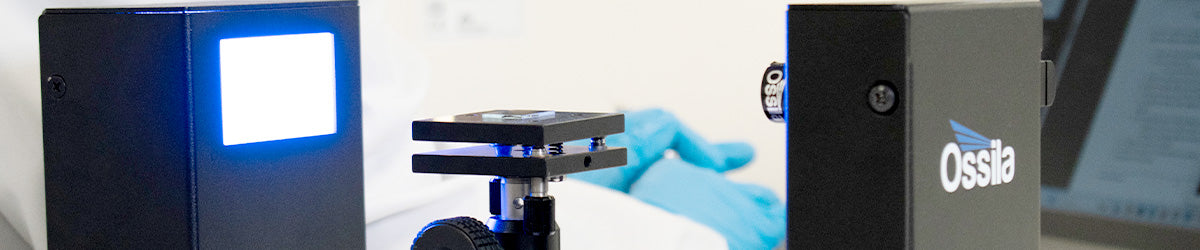

A contact angle goniometer is an instrument that measures the contact angle of a droplet on a surface. This is a useful, indirect measurement of surface wetting. When a droplet starts to spread out over a surface, its contact angle becomes <90°. Complete wetting occurs when the droplet is flat, or in other words, when the droplet has a contact angle of 0°. By suspending a droplet from the tip of a needle and comparing droplet models to the image captured by the system, contact angle goniometers can also be used to perform optical tensiometry measurements.

The instrument consists of a few key components: a tilting stage, a monochromatic light source, a high resolution camera, and contact angle analysis software.

Applications

Contact angle measurements are a fundamental tool in researching a huge variety of topics. Almost any field of materials science can learn something from a contact angle measurement. The examples given below are just a few of the many applications that the goniometer can be used for.

Thin Film Scale-Up

For solution-processable technologies such as perovskite solar cells or OLEDs, moving from laboratory-scale device fabrication to a commercial scale is one of the great challenges in research. Scalable deposition techniques are being used to create increasingly large devices. For instance, a researcher who usually fabricates devices using a spin coater may want to create larger devices by using a slot die coater. To do this, they will require new inks with different wettability levels. The Contact Angle Goniometer allows them to quickly identify the solutions that will wet to a substrate surface and form uniform thin-films.

Material & Solvent Compatibility

When solution processing thin film electronic devices, it is common to deposit a new material layer on top of another previously-deposited layer. The choice of solvent and processing technique will determine whether or not this is possible. If the first layer in the stack can be dissolved in the same solvent as the second, damage can occur. A contact angle measurement can help you find out if the solution you deposit is penetrating the layer that it is deposited onto.

Substrate Cleaning

The contact angle of a droplet is partly determined by the surface on which it is deposited. The goniometer can therefore be a useful tool for determining substrate cleanliness and making sure there are no unwanted pieces of dust or dirt on the substrate. For example, when using an UV ozone cleaner to remove organic contaminants from an ITO substrate, a contact angle measurement allows you to directly measure the success of your technique.

Hydrophobic Coating

Sometimes we do not want a solution to wet well to a surface, and coatings are developed to force a liquid to dewet upon contact. The goal of a hydrophobic coating is therefore to create a high contact angle between a liquid and a substrate. A contact angle goniometer is a required piece of equipment for studying and improving these coatings.

Contact Angle Goniometer