Source Measure Unit

Lab Equipment, Solar SimulatorPrecise and Versatile I-V Measurement of a Range of Devices

Source voltage and measure voltage & current reliably and easily

Overview | Specifications | Features | Gallery | Software | In the Box | Resources and Support

Designed for scientists and engineers working on the next generation of electronic devices, the Ossila Source Measure Unit is one of our most adaptable and fundamental pieces of equipment.

Measure the I-V characteristics of many devices including photovoltaics, LEDs and OLEDs, transistors, and more. The source measure unit contains four instruments on one board — two SMUs (voltage source, current sense) and two precision voltage sense channels. There is also a general-purpose shutter/trigger which enables it to control (or be controlled by) other instruments.

We have used our SMU to develop the Ossila Four-Point Probe to measure sheet resistance, our Solar Cell IV Test System and LED Measurement System to measure IV curves and characterize solar cells and LEDs, and the Ossila Potentiostat for cyclic voltammetry.

Two-Year Warranty

Buy with confidence

Compact

Space-saving design

Wide Current Range

Capable of measuring between 10 nA and 200 mA

Free Software

Easily controllable with free PC software

Specifications

Source Measure Units (SMU 1 & SMU 2)

The SMUs output a voltage and then measure both the voltage and current. The output voltage is always measured on the output to the BNC, rather than assuming it is at the set voltage. This is to account for any load effects, for example, short circuiting the output, or low impedance causing a small drop in voltage. Each source measure unit has multiple current ranges, so that you can measure both large and small currents with accuracy.

Voltage Source Specifications

| Range | Accuracy | Precision | Resolution |

|---|---|---|---|

| ±10 V | 10 mV | 333 µV | 170 µV |

Voltage Measure Specifications

| Range | Accuracy | Precision | Resolution |

|---|---|---|---|

| ±10V | 10 mV | 50 µV | 10 µV |

Current Measure Specifications

| Range | Max Current | Accuracy1 | Precision2 | Resolution | Burden |

|---|---|---|---|---|---|

| 1 | ±200 mA | ±500 µA | 10 µA | 1 µA | <20 mV |

| 2 | ±20 mA | ±10 µA | 1 µA | 100 nA | <20 mV |

| 3 | ±2 mA | ±1 µA | 100 nA | 10 nA | <20 mV |

| 4 | ±200 µA | ±100 nA | 10 nA | 1 nA | <20 mV |

| 5 | ±20 µA | ±10 nA | 1 nA | 0.1nA | <20 mV |

1Accuracy has been measured at the maximum current of the range.

2Precision has been measured at the highest OSR (9).

Precision Voltage Meter Specifications (Vsense 1 and Vsense 2)

The voltage meters are designed to accurately sense small voltages while also having a wide dynamic range (±10 V).

| Range | Accuracy | Precision | Resolution |

|---|---|---|---|

| ±10 V | 10 mV | 50 µV | 10 µV |

Shutter/Trigger

The Shutter/Trigger can be used either as an input or an output. It can be used to send a trigger signal to other instruments or configured to wait for a trigger from other instruments. The voltage level of this BNC is 5 V because any higher may cause damage to the port.

Physical Specifications

| Computer Connectivity | USB-B and Ethernet |

|---|---|

| Measurement Connections | BNC connector |

| Dimensions (L x W x H) | 185 mm x 125 mm x 55 mm (7.28" x 4.92" x 2.17") |

Manuals

Source Measure Unit user manual

Source Measure Unit programming documentation

Source Measure Unit Features

Five Independent Channels

Features dual source measure and voltmeter channels. Two SMU channels output voltage while measuring current and/or voltage, and two separate voltage measurement channels measure voltage sourced by external components. The shutter/trigger channel allows external control and programming.

Wide Voltage and Current Range

Choose between five separate current ranges to suit your experimental needs. Plus, 10 different speed/resolution settings. Take measurements at DC or low frequency over a voltage range from -10 V to +10 V, with a current flow from 10 nano-amps (nA) to 200 milliamps (mA).

Flexible and Scalable Communication

Expand your experimental capabilities by connecting the source measure unit via USB, or use several units at the same time via Ethernet connection.

Choose Your Preferred Programming Language

The user-friendly design works with almost any programming language. Common compatible languages include Python, MATLAB, Java, C/C++, and more.

Source Measure Unit Gallery

Testimonials

The Source Measure Unit is a professional alternative to old-fashioned and outdated bench top source-measure units at a fraction of cost. Ossila's product was thoroughly tested by us, it had to compete with state-of-art devices and to our surprise it won the race in all categories: precise PV measurements, networking capabilities, flexibility of programming language and smooth operation in pretty tough chemical/material science laboratories. The Ossila team has delivered a game changer for all of the PV community.

Adam Surmiak, PhD Student in Excitonic Systems for Solar Energy Conversion

Monash University, Australia

Software

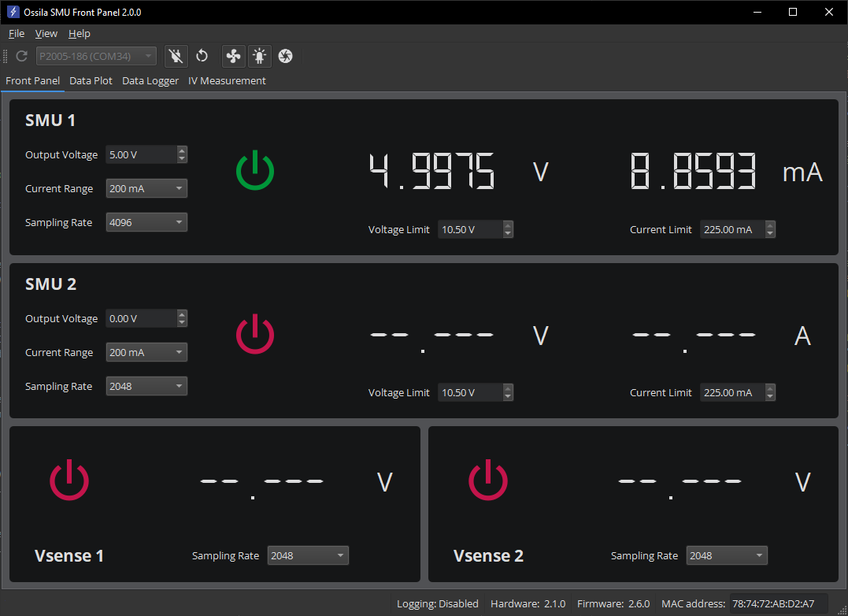

The Ossila Source Measure Unit includes Front Panel software that enables you to start taking measurements as quickly as possible. With the program you can:

- Control each SMU and Vsense channel independently, allowing you to perform many of the most common electrical measurements.

- Set voltage and measure current with two independent SMU channels (voltage source, current sense).

- Quickly and accurately measure voltages with the two Vsense channels.

- Easily set sampling rates for the SMUs and Vsense channels via the interface.

- Save your data as a portable spreadsheet (.csv) file or a text (.txt) file for analysis with your favourite software package.

Other Software

We also have software for performing specific measurements with the Ossila Source Measure Unit. These can be downloaded for free from our software and drivers page. The currently available measurements are:

- I-V curves

- Solar cell characterization and lifetime

- Four-point probe sheet resistance

Programming Languages

The user-friendly design works with almost any programming language. Common languages that can be used to interface to it are:

Software Requirements

| Operating System | Windows 10 or 11 (64-bit) |

|---|---|

| CPU | Dual Core 2 GHz |

| RAM | 4 GB |

| Available Drive Space | 200 MB |

| Connectivity | USB 2.0, or Ethernet (requires DHCP) |

In the Box

The standard items included with the Ossila Source Measure Unit are:

- Source measure unit

- 24 V / 2 A DC power adapter

- USB-B cable

- User manual and QC data

- USB drivers and Front Panel software installer

- USB Driver with QC test data

Resources and Support

I-V Curves: A Guide to Measurement

I-V Curves: A Guide to Measurement

An I-V curve (short for 'current-voltage characteristic curve'), is a graphical representation of the relationship between the voltage applied across an electrical device and the current flowing through it.

Read more... SMU Quickstart Guide

SMU Quickstart Guide

The latest quick start guide for the Ossila Source Measure Unit, to set up your device

Read more...