Molybdenum Tungsten Disulfide (MoWS2) Powder

CAS Number 109657-36-5

2D Materials, Low Dimensional Materials, Materials, Transition Metal Chalcogenides (TMCs), Transition Metal Dichalcogenides (TMDs)MoWS2 high purity powder

Used to prepare quantum dot solutions and nano-platelets

Technical Data | MSDS | Structure | Literature and Reviews | Related Products | Resources and Support

Molybdenum tungsten disulfide (MoWS2), CAS number 109657-36-5, is a transition metal dichalcogenide (TMDC) alloy. Alloying 2D TMDCs is an effective way of practically modulating the band gap. This is because alloys have good thermodynamic stability at room temperature.

High Purity

MoWS2 high purity powder

Worldwide Shipping

Quick and reliable shipping

Low Cost

Low Cost Molybdenum Tungsten Disulfide Powder

Applications

Used to prepare quantum dot solutions and nano-platelets

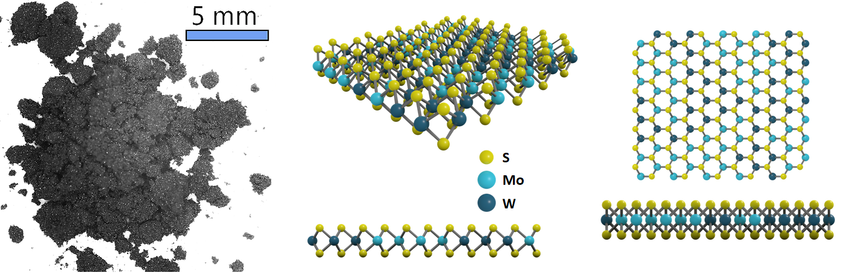

Like molybdenum disulfide powder and tungsten disulfide powder, MoWS2 powder has a layered hexagonal crystal structure. The bulk alloys are formed by stacking monolayer alloy together via van der Waals interactions. Each monolayer contains one MoW plane sandwiched by two S planes, represented as an S-MoW-S layer.

Technical Data

| CAS Number | 109657-36-5 |

| Chemical Formula | MoWS2 |

| Molecular Weight | 204.01 g/mol |

| Bandgap | ~1.90 eV [1] |

| Preparation | Synthetic - Chemical Vapour Transport (CVT) |

| Structure | Hexagonal |

| Electronic Properties | 2D Semiconductor |

| Melting Point | N/A |

| Colour | Black |

| Classification / Family | Transition metal dichalcogenides (TMDCs) alloy, 2D semiconductor materials, Nano-electronics, Nano-photonics, Materials science |

Product Details

| Form | Purity |

|---|---|

| Powder | ≥99.995% |

Pricing Table

| Product Code | Form | Quantity | Price |

|---|---|---|---|

| M2141C1 | Powder | 500 mg | £220 |

| M2141C1 | Powder | 1 g | £360 |

MSDS Document

Molybdenum tungsten disulfide powder

Molybdenum tungsten disulfide powder

Structure of Molybdenum Disulfide Powder

Literature and Reviews

- Towards band structure and band offset engineering of monolayer Mo(1−x)W(x)S2 via Strain, J.-S. Kim et al, 2D Mater. 5, 015008 (2018); doi: 10.1088/2053-1583/aa8e71.

- Experimental and First-Principles Investigation of MoWS2 with High Hydrogen Evolution Performance, H. Li et al., ACS Appl. Mater. Interfaces 2016, 8, 29442−29451; DOI: 10.1021/acsami.6b09620.

- Ordered and Disordered Phases in Mo1−xWxS2 Monolayer, W. Tan et al., Sci. Rep., 7:15124 (2017); DOI:10.1038/s41598-017-15286-9.

Related Products

We stock a wide range of 2D materials available to purchase online. Please contact us if you cannot find what you are looking for.