PEDOT and PEDOT:PSS Synthesis

PEDOT synthesis involves the oxidative chemical or electrochemical polymerization of EDOT monomer. The choice of counterions and polymerization method significantly affects the conductivity, work function, and stability of the resulting PEDOT polymer. For example, PSS is commonly used as a counterion to form PEDOT:PSS.

PEDOT Synthesis

PEDOT is synthesized from 3,4-ethylenedioxythiophene (EDOT) monomer. The chemical cross-coupling polymerization of EDOT happens primarily at 2,5-postions of the thiophene ring adjacent to the sulfur atom. The 3- and 4-positions of the thiophene ring are both occupied by oxygen atoms as part of the ethylenedioxy group. They block unwanted polymerization reactions that could lead to cross-linking between PEDOT polymer chains. The oxygens are electron-donating which increases the electron density of the thiophene ring. This facilitates the synthesis of PEDOT via oxidative or electrochemical polymerizations.

PEDOT can be prepared mainly through the following three polymerization reactions:

- Oxidative chemical polymerization

- Electrochemical polymerization

- Transition metal-mediated coupling (Yamamoto)

As polymerization of EDOT using transition metal-mediated coupling produces insoluble and therefore non processable PEDOT this method will not be discussed on this page. A brief comparison of oxidative chemical and electrochemical polymerization of PEDOT can be found in the table below:

| Polymerization | Oxidative Chemical | Electrochemical |

| Components |

Substrate Oxidant/Catalyst Solvent Optional: Surfactant, Inhibitor, Cosolvent |

Substrate (working electrode) Electrolyte Solvent |

| PEDOT Form |

Coated on substrate |

Grown on substrate |

| How to change PEDOT properties |

Change the components used including counterion

|

Changing applied potential and direction Change counterion |

Oxidative chemical polymerization

Oxidative chemical polymerization of EDOT monomers is the most popular method to prepare solution processable PEDOT on a large scale. It involves multiple steps:

- Oxidation of the EDOT monomer to form cationic radicals

- Free radical dimerization

- EDOT dimer deprotonation

- EDOT dimer oxidation and polymerization

The most common and effective oxidants for the synthesis of PEDOT have been iron (III) complexes such as iron(III) chloride and iron(III) tosylate. Counter ions (Cl-, Tos-, sulphonate) stabilize the oxidized cationic PEDOT and contribute their own properties to the conductive polymer.

Other oxidant metal ions include:

- cerium (IV)

- manganese (IV)

- copper (II)

The counter ion tosylate leads to a higher degree of polymerization and conjugation compared to chlorine. This is the result of a slower rate of oxidation and smoother film microstructure. A PEDOT-Tos film therefore has greater conductivity than PEDOT-Cl.

In a solution of iron (III) tosylate and EDOT in butanol, iron (III) serves as the oxidizing agent and tosylate as the doping counter ions. The oxidizing and doping process introduces dopant molecules into the polymer matrix, altering its electronic properties. Iron (III) tosylate acts as a charge carrier within the PEDOT matrix, improving its conductivity. Doping concentration can also influence the morphology, stability, and mechanical properties of the polymer.

There are two techniques used in PEDOT device fabrication based on oxidative chemical polymerization:

Solution-cast Polymerization

- Dissolve EDOT and the oxidant in alcohol (butanol) to form a clear solution.

- Apply the solution onto the substrate or matrix using a spin coater, dip coater, or spray coater.

- Control coating thickness by adjusting parameters such as solution concentration, coating speed, and drying conditions.

- Anneal the coated substrate to assist the polymerization process.

- Rinse or wash the substrate with polar solvent to remove any unreacted monomer, oligomer, catalyst, or by-products.

Vapor Phase Polymerization

- Apply a solution of oxidant and additive onto a substrate by solution processing techniques such as spin coating, dip coating, or spray coating.

- Expose the coated substrate to an atmosphere of EDOT monomer vapor in a sealed chamber.

- EDOT polymerization happens on the surface of oxidant layer on the substrate to form the polymer film of PEDOT in situ.

- Wash the deposited film with solvent to remove residual oxidant and unreacted monomer or oligomers.

By performing in-situ polymerization of PEDOT with different oxidants, customized conductive polymer materials can be created with controlled properties tailored to specific applications.

Other components can be incorporated into the polymerization process to control properties such as:

- Block copolymer surfactant

- High boiling point cosolvent

- Pyridine inhibitor

Electrochemical Polymerization

Electrochemical polymerization of EDOT is a process used to obtain conducting polymer PEDOT thin film on a desired substrate. This is normally the working electrode which undergoes electrochemical oxidation. A three-electrode (working, reference, and counter electrode) electrochemical cell is filled with an electrolyte solution that contains EDOT.

A potential between the working and counter electrodes causes oxidation of EDOT monomers at the surface of the working electrode. This leads to the formation of radical cations. These radical cations subsequently polymerize to form PEDOT polymer chains. A thin film of PEDOT subsequently develops on the surface of the working electrode substrate. The anions of electrolyte are doped into PEDOT as counterions to stabilize the charge in PEDOT.

Common Electrolytes:

- lithium perchlorate (LiClO4)

- 1-butyl-3-methylimidazolium hexaphonate (BMIMPF6)

- lithium bis (trifluoromethosulfonyl) amide (LiTFSI)

Both oxidative chemical and electrochemical polymerization of PEDOT require a substrate support. The transparent and conductive nature of PEDOT makes it highly suitable for a range of applications including in photovoltaics, OLEDs, sensors, and supercapacitors. It can be difficult to process PEDOT due to it’s hydrophobic nature. This problem has been resolved by incorporating a different hydrophilic polymer (polystyrene sulfonate – PSS).

PEDOT:PSS Synthesis

PEDOT:PSS is synthesized by polymerizing EDOT in the presence of polystyrene sulfonate (PSS). PEDOT:PSS can be rigid or flexible with tunable conductivity. It can also be coated on a range of substrates. Crucially, the hydrophilicity of PSS counterion means that PEDOT:PSS is highly stable in aqueous solutions.

Oxidative chemical polymerization of EDOT in water:

- Na2S2O8 as the oxidizing agent

- EDOT oxidized to cationic radicals

- Fe2(SO4)3 as the catalyst

- PSSNa as stabilizing agent (PSS- as the counterion) and template for PEDOT polymerization.

A nano-sized core-shell structure is formed between PEDOT and PSS with PEDOT predominantly as the core and PEDOT as the shell. The two polymers are bound by Columbus force. The negatively charged deprotonated sulfonic acid ion have a stabilizing effect on the positively charged oxidized PEDOT cations.

PEDOT:PSS offers good chemical, thermal and UV stability, great optical transparency, great range of conductivity up to thousands of S cm−1. The conductivity of the PEDOT:PSS is tuned by varying the ratio of PEDOT:PSS. The greater the amount of PEDOT the greater the conductivity. This is as a result of larger areas of crystallized PEDOT which increases the carrier mobility including improved intra- and inter-chain transport.

Conductivity can also be tuned with secondary dopants after polymerization. Secondary dopants increase conductivity by changes in electronic spectra and degree of PEDOT crystallinity. Examples of secondary dopants include:

- Polar and high boiling point solvents

- Ionic liquids

- Anionic surfactants

- Salts

As well as dopants, other processing methods can be used to increase conductivity. Treatment with strong acids, oxygen plasma and other solvents can lead to increased crystallinity of PEDOT which increases conductivity.

PEDOT Polymer Blends

Learn More

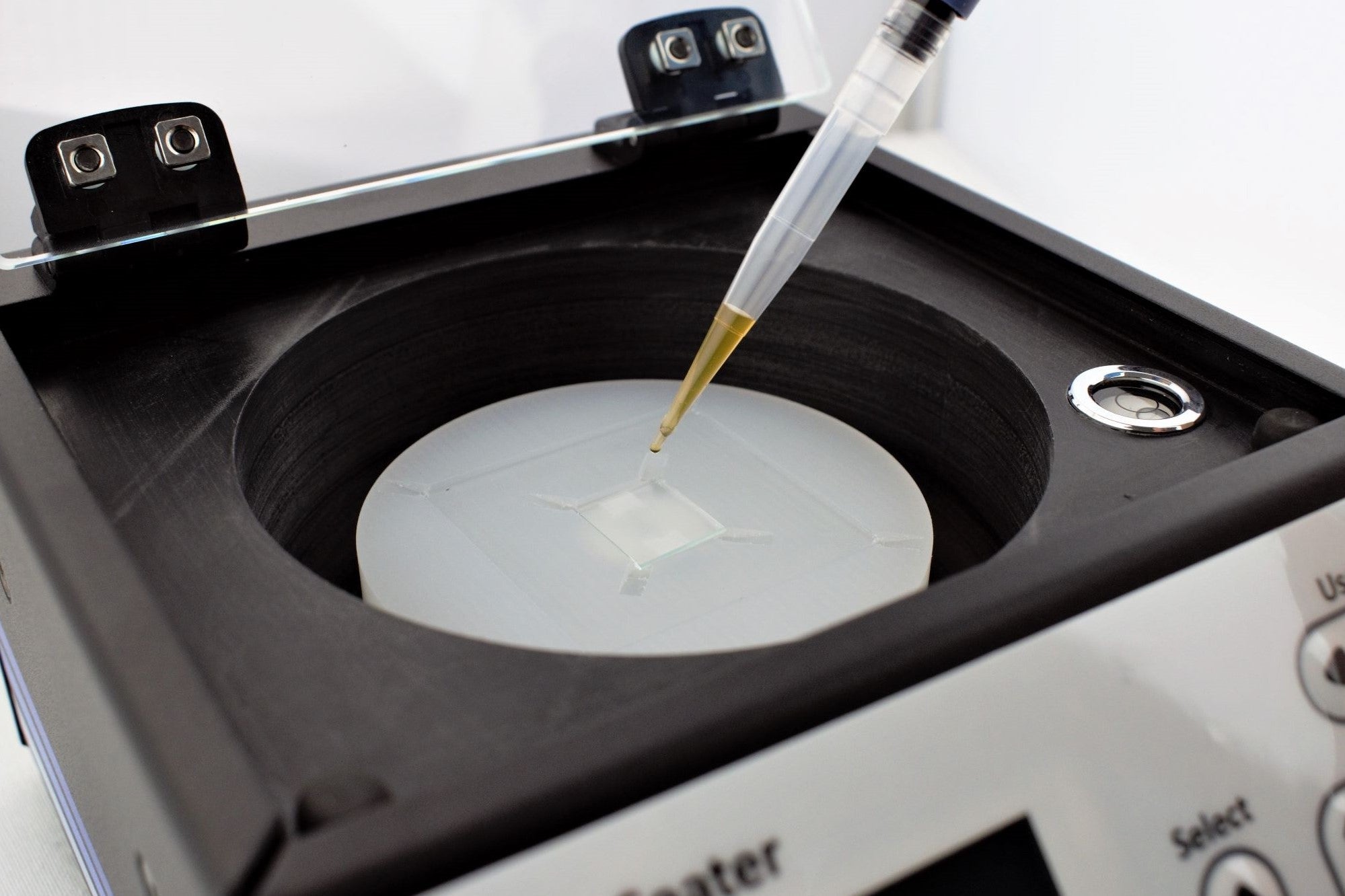

How to Spin Coat PEDOT:PSS

How to Spin Coat PEDOT:PSS

For the deposition of thin films of PEDOT:PSS on a freshly prepared surface, we recommend using a vacuum-free spin coater and following this five-step process:

Read more...PEDOT:PSS has conductivities in the range of 10-4 - 103 S cm-1. PEDOT:PSS is conductive because it contains the conjugated intrinsically conductive polymer (ICP) PEDOT.

Read more... PEDOT:PSS Conductive Polymer

PEDOT:PSS Conductive Polymer

PEDOT:PSS is a blend of two distinct polymers: poly(3,4-ethylenedioxythiophene) (PEDOT) and polystyrene sulfonate (PSS). This combination forms a p-type semiconductor which is highly valued for its ability to conduct electricity and its ease of processibility.

Read more...References

- Nie, S. et al. (2021). Progress in Synthesis of Conductive Polymer Poly(3,4-Ethylenedioxythiophene), Front. Chem., 9.doi:10.3389/fchem.2021.803509

- Yamamoto, T. et al.(1999), Synthesis of non-doped poly(3,4-ethylenedioxythiophene) and its spectroscopic data, Synth. Met., 100(2), doi:10.1016/S0379-6779(99)00005-3

- Gueye, M. et al.(2020). Progress in understanding structure and transport properties of PEDOT-based materials: A critical review. Prog. Mater. Sci., 108, doi:10.1016/j.pmatsci.2019.100616

Contributors

Reviewed and edited by

Application Scientist

Diagrams by

Graphic Designer