Getting Started with the Ossila Spin Coater

What is Spin Coating?

Spin coating is a widely used and versatile technique for depositing materials onto substrates with accurate and controllable film thicknesses. A spin coater uses the centripetal force and surface tension of the solution to create an even film, making it quicker than other thin film coating methods. This makes it ideal for batch processing in both research and industrial settings. Spin coating is often used as the starting point and reference for many thin-film processes, even if they will eventually get mass-produced using printing-based techniques.

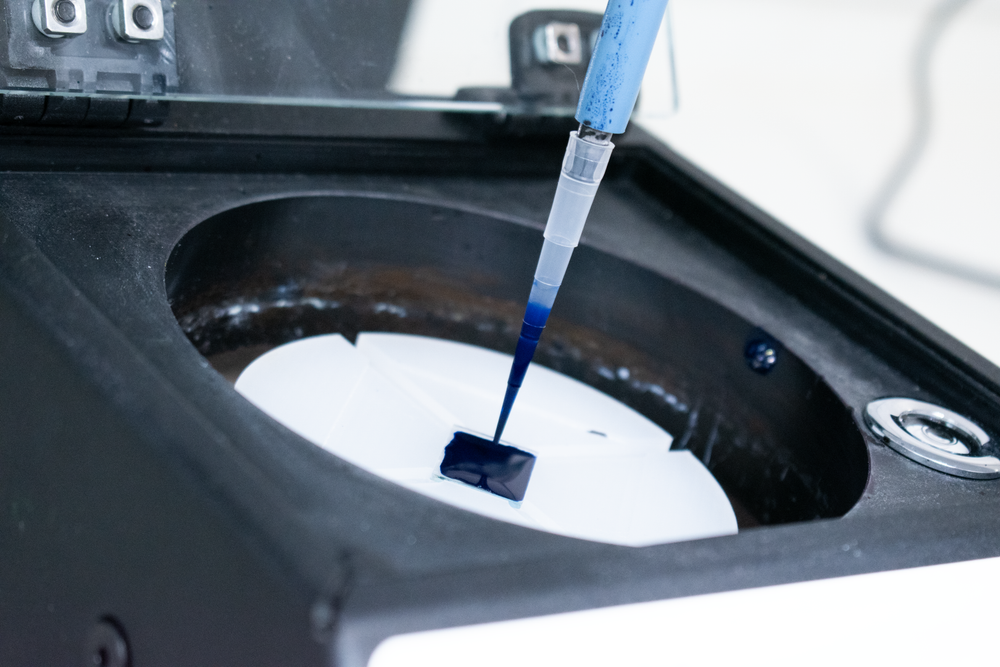

A spin coating cycle consists of four key stages: disposition, spin up, spin off, and evaporation. First, a solution is cast onto the substrate using either a syringe pump or a micropipette. Then, the solution is pushed outwards by the centripetal force so that it covers the surface of the substrate. At this point, most of the excess ink is expelled to the side and airflow begins to dry the film. Finally, in the last stage, the solvent evaporates to leave a thin, uniform film behind.

Spin Coating Thickness Equation

The underpinning physics behind spin coating is relatively simple, as are the equations that govern the resulting film thickness, which is proportional to the inverse of the spin speed squared. The Ossila Spin Coater gives complete control over the spin speed and allows different spin sequences to be programmed.

The exact relationship between spin speed and film thickness depends on the solution being used, and is often worked out empirically, though models such as the Emslie, Bonner, and Peck model and Meyerhofer model attempt to describe the fluid dynamics involved mathematically.

Going Further with Spin Coating

For advanced deposition techniques using spin coating, the timing and solution dispense rate is critical. In these situations, the dispensing of solution should switch from a manual process to an automated process. We recommend the use of a syringe pump that allows you to control the rate and volume of the dispensed solution, as well as the start time.

Our dual syringe pump is able to control the dispensing of two different solutions independently. Like the Ossila Spin Coater, both models of syringe pump come with integrated software controls built into the system for easy computer-free operation.

Use of a syringe pump will allow you to easily perform spin coating tasks such as:

- Solution-processed multilayered structures

- Solvent quenching of deposited films

- Surface modification of films by solvent washing

- Improved wetting of films by pre-coating the surface with a carrier solvent

Spin Coater