Types of Linear Stage

Linear stage systems can have an array of features and specifications. With this, precise linear motion can be implemented into a wider variety of applications.

We have developed a range of linear stage products which vary by level of precision, axis motion, and travel length.

Motorized and Manual Stages

Motorized

Equipped with electric motors for automated and highly accurate linear motion, motorized linear stages offer controlled and repeatable positioning. They are ideal for industrial automation, semiconductor manufacturing, microscopy, and scientific research.

Our linear stages are equipped with an intelligent stepper motor controller and intergrated rotary encoder. This enables you to move equipment and samples precise distances easily.

Manual

Manual linear stages are mechanically adjusted by hand. When you turn the handle, the carriage moves along a straight path. They are straightforward and cost-effective solutions for applications where automation is not required.

While lacking the precision and automation of motorized stages, manual linear stages find utility in educational settings, prototyping, and situations where simplicity and budget constraints are paramount.

Multi-Axis Stages

Single Axis

Designed for movement along a single axis, X linear stages enable precise, horizontal movement. They are crucial components in various applications that require precise positioning in one dimension, including optical component alignment, materials handling, and other basic positioning tasks.

Dual Axis

For two-dimensional motion, XY stages are used. Intricate tasks such as circuit board inspection, sample manipulation in scientific research, and material procssing, are possible with XY stages.

Triple Axis

For more advanced applications, XYZ stages offer precise three-dimensional motion. You can use these systems in various complex applications, including 3D printing, medical imaging, and microscopy.

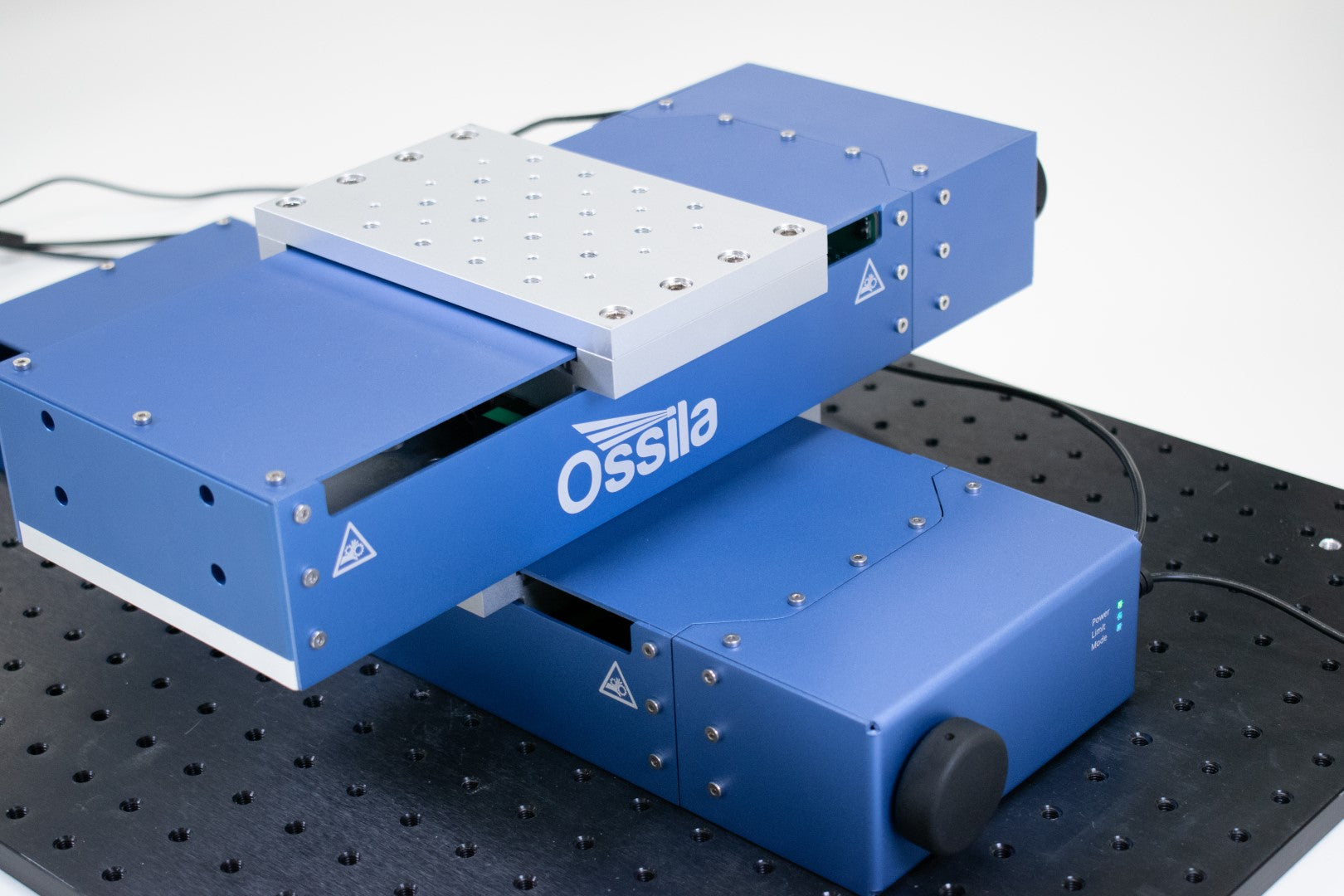

Modular

While some multi-axis stages are integrated, our systems are modular. This means you can combine multiple stages to achieve multi-axis motion, or use them independently in simpler positioning tasks.

Precision and High Precision Stages

Standard Precision

Standard precision linear stages focus on reliability and cost-effectiveness. Their drive mechanism provides moderate precision, typically in the range of micrometers to a few tens of micrometers. In our standard precision stages, we use a C7 ball screw drive.

Sample positioning, optical component alignment, and basic materials handling are a few of the applications that often employ standard precision linear stages. They offer a balance between accuracy and affordability, making them accessible for various applications where tight tolerances are not critical.

High Precision

High precision linear stages provide a higher level of accuracy and repeatability. They incorporate advanced components, such as C5 ball screws, to achieve reduced error values.

In sectors where the strictest tolerances are essential, including semiconductor manufacturing, microscopy, and nanotechnology, these stages are essential.

Standard and Long Travel Stages

Standard Travel

Standard travel linear stages focus on providing a fixed travel distance, typically around 100mm. Offering precise motion over a predetermined range, they are suitable for benchtop lab-based applications.

These stages are cost-effective solutions for applications with restricted motion requirements.

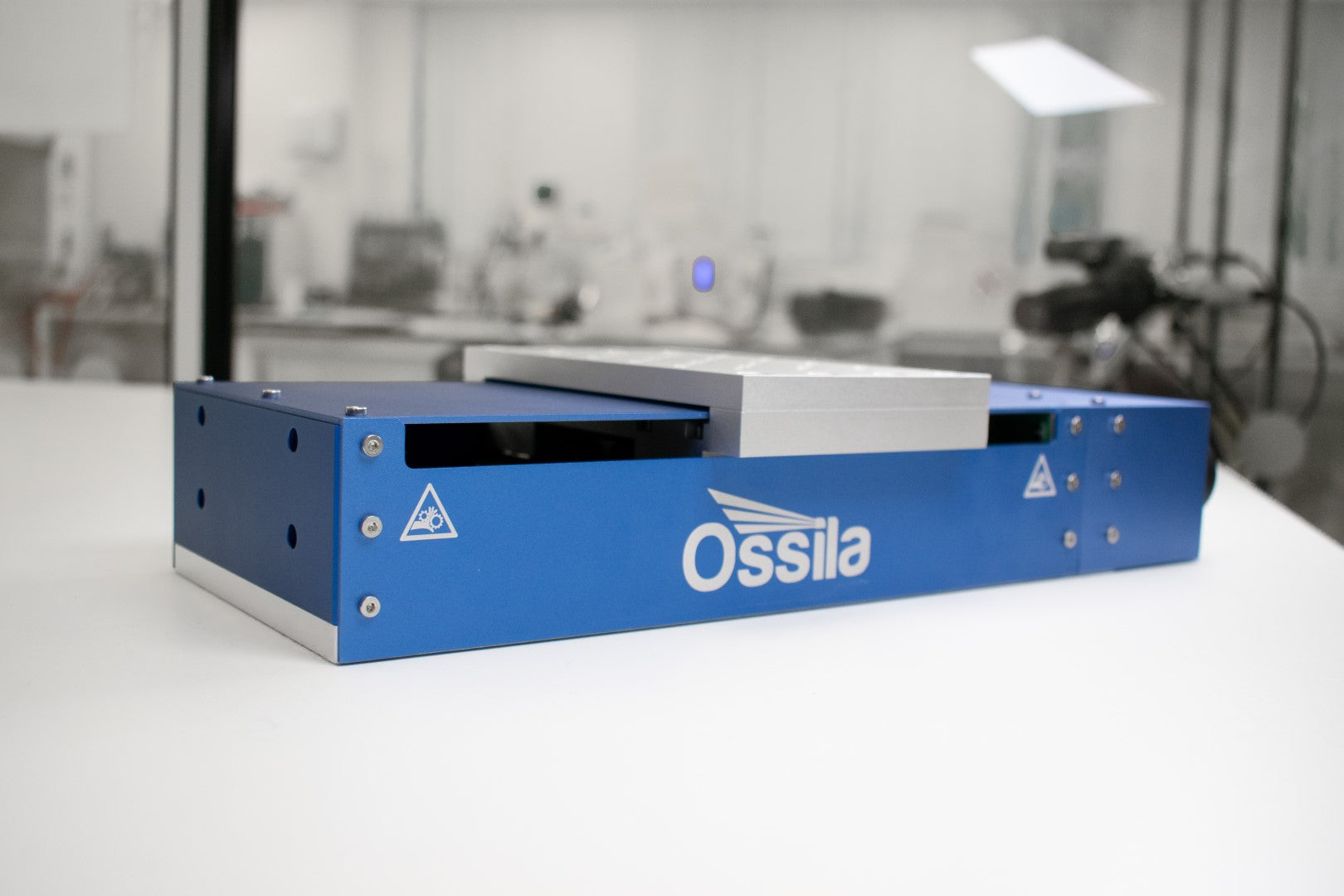

Long Travel

Long travel linear stages enable extended linear motion over greater distances. They often feature larger dimensions and a robust construction to accommodate extended travel lengths, from 200mm to several meters.

Our 200mm stages, remove travel resrictions in lab-scale applications. Whereas, in tasks such as heavy load transport, automated assembly lines, and the manipulation of oversized components, even longer stages are used.

Linear Stage

Learn More

Do You Need a Linear Stage?

Do You Need a Linear Stage?

Whether you are involved in microscopy, spectroscopy, or metrology, a linear stage can be an invaluable tool. The decision to invest in a linear stage depends on the specific requirements of your application.

Read more... How to Choose a Linear Stage

How to Choose a Linear Stage

Based on your research needs, there are key factors to consider when selecting a linear stage.

Read more...We used pre-trained AI to help us write this page. As part of our editorial process, our in-house experts review, fact-check, and edit all AI-generated content to make sure we provide you with accurate and helpful information.