Spin Coating in Laminar Flow Hood

To achieve successful thin-film deposition via spin coating, it is crucial to minimize particle contamination. Our laminar flow hood in the vertical configuration can create a contamination free environment by:

- Physically removing particles from the air with HEPA filtration.

- Controlling laminar air flow ensuring that any contamination brought into the workspace is quickly removed.

- Creating downward air flow that flows around the spin coater.

This guide will walk you through some important steps to help you establish a clean and effective process using a spin coater inside a laminar flow hood.

Can You Spin Coat in a Laminar Flow Hood?

In short, yes. Spin coating inside a laminar flow hood will increase the uniformity of your films massively compared to spin coating on a typical lab bench.

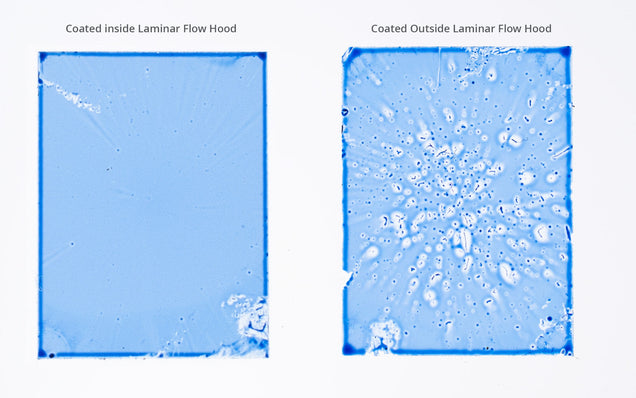

This photo shows two films, one spin coated in a laminar flow hood (left) and one in a general lab environment (right). We can see that the amount of comets and defects are significantly reduced when coated inside the laminar flow hood. The few comets and particulates on the smoother film are likely from the solution or substrate themselves. You can further improve film quality by

- Cleaning the substrates more thoroughly

- Filtering solution before deposition

Preparation

Before spin coating in a laminar flow hood, we would recommend that you:

- Clean all equipment thoroughly before bringing into the laminar flow hood. Remember to wipe down the outside of your equipment too.

- Clean the laminar flow hood itself.

- Make sure you remove all dust and contaminate particles that could be disturbed by the air flow.

- Allow your equipment to sit in the laminar flow hood for a few minutes after putting it in.

- Always level your spin coater after placing it in a new environment.

Cleaning Substrate with UV Ozone

UV ozone cleaning is a useful step used to clean and improve the wettability of your substrates. Most UV Ozone cleaning should take place inside a fume hood to absorb UV Ozone produced.

If you have treated your substrates with a UV ozone cleaner, you will need to move them from the fume hood to the laminar flow hood in a protected case, like a sample box.

You must place your clean substrates into the sample box within the fume hood environment. Ideally, do this as close to the UV Ozone tray as you can. Close the box within the controlled environment, then you can remove.

Once the substrates are within the laminar flow hood, you can open the box and move your substrates wherever you need. This may seem overly cautious - but even short exposure to uncontrolled unfiltered air can compromise your spin coating process.

Tips When Spin Coating in a Laminar Flow Hood

The spin coater should be used in a vertical laminar flow hood, as it will not interrupt laminar air flow in this configuration. However, as the air flow is downwards in these systems, there are some important Dos and Don'ts you need to consider to avoid user contamination of your samples.

| Do Not | Do |

|---|---|

| Don't move contaminated materials over the substrates or coating equipment. | Always keep the waste streams away from any contaminating air streamlines. |

| Do not move your hands over the coating area or substrates. | Organize your workspace to minimize reaching over equipment as much as possible. |

| Avoid holding pipettes directly over substrates, as dust can fall from your gloves or pipette onto your substrate. | Hold the pipette at a slight angle to prevent dust contamination. |

| Do not place gloved hands over the substrates as you move them into the spin coater. | Close the lid gently before starting the spin coating process. |

Laminar Flow Hood

Learn More

Laminar Flow Hood Cleaning Procedure

Laminar Flow Hood Cleaning Procedure

To ensure the cleanliness of your laminar flow hood, it is essential to use the following steps. First, begin by applying a disinfectant spray to the air at least 10 minutes before commencing any work. This step serves to neutralize charges on colloidal particles, causing them to precipitate from the air.

Read more... How to Assemble the Vertical Laminar Flow Hood

How to Assemble the Vertical Laminar Flow Hood

Assembly Instructions for Vertical Laminar Flow Hood: Firstly, begin by attaching the baffle to the plenum. Align the plenum using the threaded studs and secure it in place using the nuts provided.

Read more...