Latest News

The Spray Coater: Benchtop System for Simple Scale Up

Posted on Mon, Jan 12, 2026 by Imogen Pass

A pre-order sell out, the newly launched Ossila Spray Coater builds on the success of our Automatic Film Applicator. Designed to simplify your scale up processes, work with larger, textured, or curved substrates to easily adjust essential parameters for coating optimization. Achieve a range of droplet sizes and spray patterns...

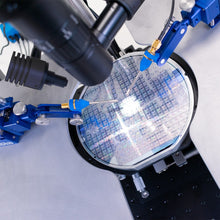

The Ossila Probe Station: High Performance at a Fair Price

Posted on Tue, Sep 16, 2025 by Imogen Pass

A professional probe station at a fair price. The Ossila Probe Station challenges the industry norms of high-cost, over-engineered systems. Designed for small-scale electronics experiments, this system provides a simple and stable foundation for manual probing to produce clean, reliable data. Access essential probing capabilities without destroying your research budget...

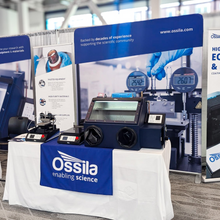

Material Science Research Spring Meeting 2025

Posted on Thu, Apr 24, 2025 by Mary O'Kane

This month, Ossila had the pleasure of attending the Material Science Research Spring Meeting in Seattle USA as an industrial sponsor. We also supported Christopher Passmore, a third year PhD student at the University of Sheffield, and student writer for Ossila, in attending the conference through our conference fund. We...

Ossila Runs the Sheffield Half Marathon for SolarAid

Posted on Wed, Mar 26, 2025 by Amelia Wood

On Sunday 23rd March, members of the Ossila team laced up their running shoes and joined 6,484 other participants in the Sheffield Half Marathon. Our team took on the rather hilly 13.1 mile course to raise money for SolarAid, an international development charity working to bring clean, renewable energy to...

Ossila at MATSUS25: Exploring Sustainable Materials

Posted on Tue, Mar 18, 2025 by Mary O'Kane

This month, we had the fantastic opportunity to attend the Materials for Sustainable Development Conference 2025 (MATSUS25) in Sevilla! Bringing together researchers from across Europe, the conference covered a broad range of topics, from next-generation battery technology to perovskite and organic photovoltaics (OPVs) to MXenes. One of the key themes...

Ossila at InnoLAE 2025

Posted on Mon, Feb 24, 2025 by Imogen Pass

Last week we attended InnoLAE 2025—a key event in the field of large-area electronics, which brings together academia and industry. We had the opportunity to exhibit our product range, discuss the latest research, and build valuable connections. At our exhibition stand, we spoke with professionals across the large-area electronics community....

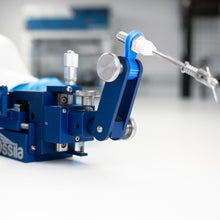

The Micromanipulator: Precision at Your Fingertips

Posted on Wed, Jan 22, 2025 by Imogen Pass

Compact and intuitive, the new Ossila Micromanipulator enables precise probing at the micron scale. Achieve high levels of precision and flexibility in delicate applications, from semiconductor characterization to advanced laboratory research. Designed with both performance and usability in mind, the micromanipulator integrates seamlessly into your probe station setup. The ergonomic...

The Automatic Film Applicator: Simple and Versatile Large Area Coatings

Posted on Fri, Jan 17, 2025 by Imogen Pass

Expand your thin film coating processes with the Ossila Automatic Film Applicator. Compatible with a wide range of applicators, this versatile system can be used to automate many different techniques to reduce errors and product defect-free coatings. The motorized stage offers smooth, continuous movement across a wide range of speeds,...

Ossila Welcomes the Lord-Lieutenant of South Yorkshire

Posted on Wed, Dec 04, 2024 by Imogen Pass

On the 2nd of December, Ossila had the honor of welcoming Professor Dame Hilary Chapman, the Lord-Lieutenant of South Yorkshire, to our Sheffield headquarters for the official presentation of the 2024 King’s Award for Enterprise in International Trade. The award, announced on the 6th of May 2024, recognizes Ossila’s significant...

Quick Measurements with the Four-Point Probe Plus

Posted on Mon, Nov 25, 2024 by Imogen Pass

The new Ossila Four-Point Probe Plus is designed to make material characterization faster and more convenient. Characterize your samples without connecting to a PC. Built with the Ossila Source Measure Unit at its core, our four-point probe has a wide current range making it suitable for a variety of measurements....

Superior Coatings, Improved Efficiency: The New Ossila Slot Die Coater

Posted on Thu, Aug 15, 2024 by Imogen Pass

The newest model of the Ossila Slot Die Coater is now available. With advanced specifications, the updated system is designed to enhance the uniformity of your films and consistently produce—and reproduce—high quality films with ease. The Ossila Slot Die Coater is a complete slot die system, with an integrated syringe...

15 Years of Ossila: From Startup to Global Leader

Posted on Fri, Jun 28, 2024 by Imogen Pass

From an ambitious startup in a small university room to a global powerhouse connecting researchers and innovators with scientific equipment and materials. Ossila was founded in 2009 by visionary scientists who wanted to do things differently—today, we have customers in every continent except Antarctica. Our journey has been shaped by...

Fluid Dynamics at Work: New Chuck Design with Advanced Spin Coater System

Posted on Mon, Jun 17, 2024 by Imogen Pass

Ossila sets a new standard in research equipment with the launch of the Spin Coater Advanced and its companion, the reinvented vacuum-free chuck. Designed to redefine precision and efficiency in thin film fabrication, these products offer enhanced control for high precision coating applications. Engineered for speed and accuracy, the Spin...

Ossila Wins 2024 King's Award for International Trade

Posted on Mon, May 06, 2024 by Imogen Pass

We are pleased to announce that Ossila has been recognized for its outstanding continuous growth in overseas sales over six years by the King's Award for International Trade. As a previous winner of the Queen's Award for International Trade in 2018, we are honoured to receive this prestigious award a...

Ossila Expands to New Location in Europe

Posted on Mon, Nov 01, 2021 by Laurence Cole

Ossila has expanded to a new location in Leiden BioScience Park in the Netherlands. For our customers in the EU, this means hassle-free delivery with zero customs issues and no unexpected fees. This builds on our pre-existing EU delivery guarantee to provide a completely frictionless purchasing experience to all our...

Ossila Wins Prestigious Queen's Award for International Trade

Posted on Sat, Apr 21, 2018 by Ashley Wong

Ossila Ltd is pleased to announce that it has been granted a Queen’s Award for Enterprise – the UK’s most prestigious award for business performance. The Awards are granted annually by Her Majesty The Queen, based on the recommendations of the Prime Minister, together with an Advisory Committee of representatives from...

Ossila Wins Prestigious Institute of Physics Award

Posted on Wed, Oct 18, 2017 by Ashley Wong

Ossila Ltd today announces that it has won an Institute of Physics (IOP) Business Innovation Award in recognition of its solar cell prototyping platform, which allows researchers to achieve world-class results and increases the pace of solar cell research in an affordable and efficient manner. This exemplary innovative platform encompasses...