What are Laminar Flow Hoods Used For?

Access to environments where the air is free from physical particulate and microbial contaminants is essential in many areas of research and manufacturing. The presence of contamination, even in very small quantities, can have a large impact on research data or the manufacturing yield. In these instances, undertaking work within a clean environment is essential.

Laminar flow hoods are an important tool in clean environment working. They provide a workspace in which clean air is continuously circulated. The air pressure inside the hood is elevated to ensure contaminated air from outside is not able to enter the workspace.

Additionally, laminar flow hoods are designed to ensure that the air present within the hood remains laminar. Turbulent air flow and the formation of vortexes, which trap contamination in air pockets or allow contaminated air back into the hood, are prevented.

Applications

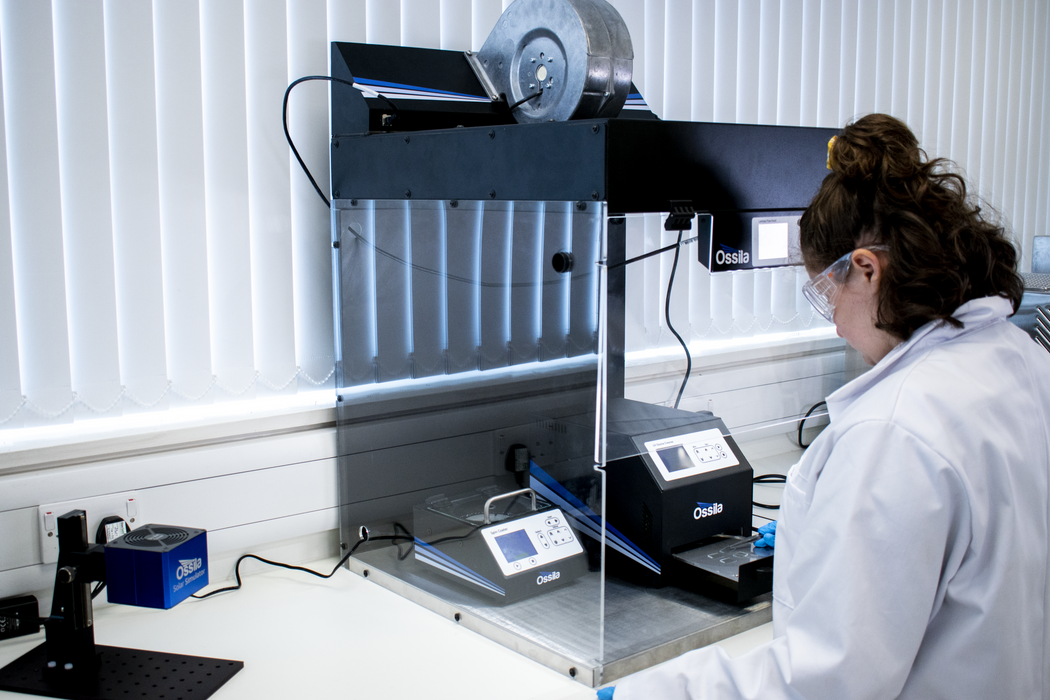

Thin Film Electronics

In electronic research and manufacturing, modern thin film devices are a strong focus. A variety of electronic devices can be fabricated using thin films. Materials are stacked on top of each other, each layer typically only being tens of nanometres thick. Through this technique, researchers can observe unique material properties that are only present in the thin film dimensions.

Processing thin film devices in a clean environment is critical to achieving high performance and for obtaining high yields within manufacturing. The presence of airborne contaminants on the surface of these devices often results in complete device failure.

The Ossila Horizontal Laminar Flow Hood and Vertical Laminar Flow Hood are equipped with HEPA filters. High quality filter technology minimizes the presence of airborne particulates in your working environment so you can push your device performance even further.

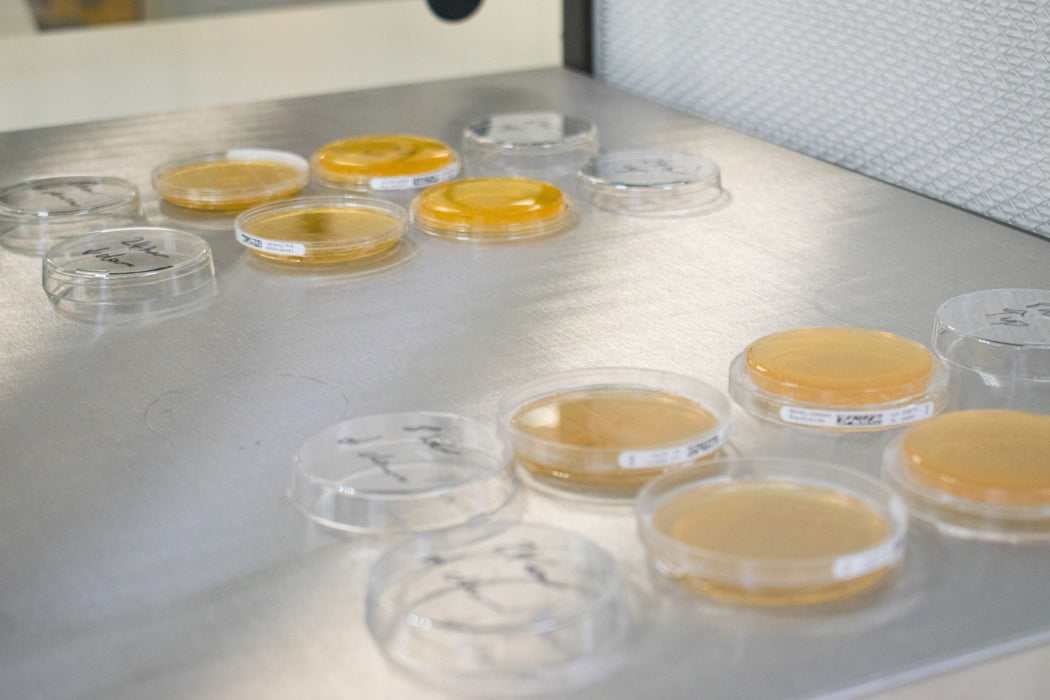

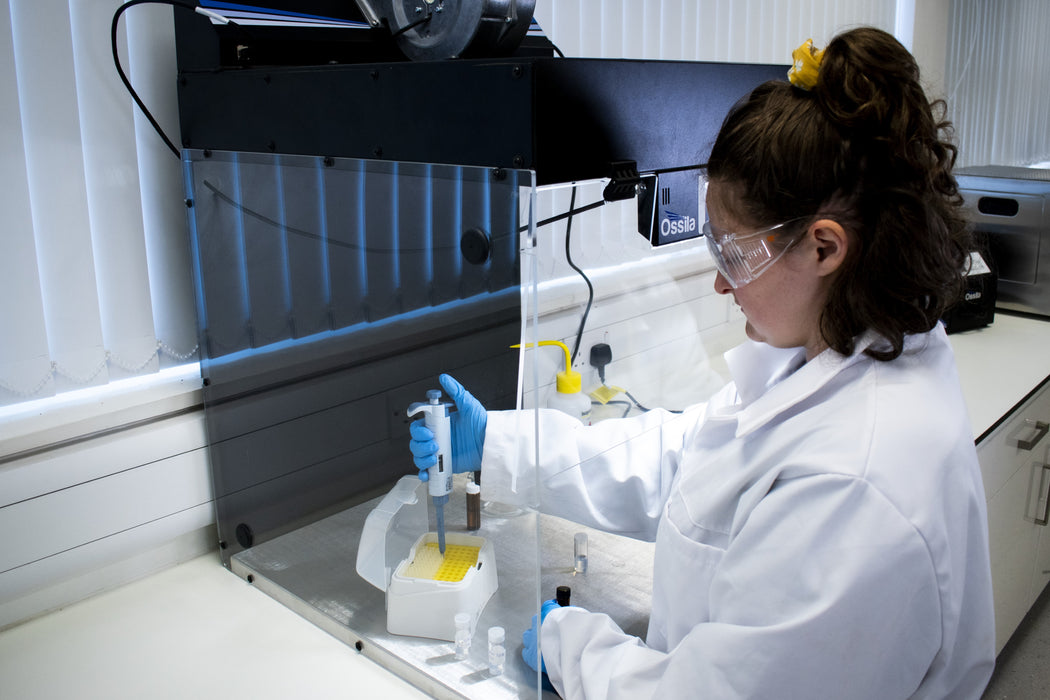

Microbiology Research

When undertaking microbiological research, cleanliness of equipment and the environment is critical. Contamination is a risk from the initial preparation of growth media to the incubation of samples. To keep your samples protected, it is important to make sure all working environments are clean.

With smart air sensing technology, the horizontal and vertical laminar flow hoods monitor the presence of airborne particulates within the hood. With an instant readout of the air quality, you have the peace of mind that your workspace is free of contaminants.

Wafer Fabrication

Wafer fabrication is the assembly of precise circuitry on the surface of semiconducting wafers. These circuits can be as small as tens of nanometers in size. To successfully manufacture at this scale, a range of processing techniques are used to pattern the surface. The patterning process is extremely sensitive to the presence of any particulate contamination and benefits from the clean environment created by a laminar flow hood.

Medical Research

Pharmaceutical production is mostly realised in highly specific formulations using batch production. For certain patients with specific needs, medication must be tailored. Similarly in research, the small-scale production of unoptimized samples often requires tailored batches. In these circumstances, pharmaceutical compounding procedures should be followed to ensure no contamination occurs.

Laminar flow is essential to avoid contamination of the work area and the samples. The Ossila Horizontal and Vertical Laminar Flow Hoods provide clean air up to ISO class 5. The optimised hood and plenum structure also maintain laminar air flow across the hood. With our advanced air filters, unidirectional flow can be preserved over longer distances and recover faster if disturbed.

Manufacturing

The use of a cleanroom environment is important for the final assembly of electro-optical, opto-mechanical, and general photonics parts. These components often use sealed systems to protect internal parts from the external environment. Despite this, the internal environment remains vulnerable to contamination throughout the manufacturing process. Assembling the components in a cleanroom environment prevents particulate materials from being trapped inside the sealed unit.

The Ossila Horizontal Laminar Flow Hood and Vertical Laminar Flow Hood provide a clean work area for component assembly. The flow of clean air ensures that no dust contaminants affect the performance of your final assembly. With variable cleanroom classification control, you can create the right environment for each process while keeping your costs to a minimum.