Evaporation Stack for OFETs, Low Density

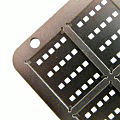

The evaporation stack holds the OFET source-drain shadow masks (sold separately) and substrates in close contact for thermal evaporation. This is crucial for effective device fabrication as the source-drain channel is usually the most critical feature on an OFET. For use with the Ossila low density OFET source-drain evaporation masks and Silicon Oxide Substrates.

Specifications

| Size | 75 mm x 75 mm |

| Thickness | 1 mm (exc. bolts) |

| Material | Stainless steel |

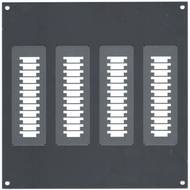

| Capacity | 12 substrates |

Architecture of an Evaporation Stack

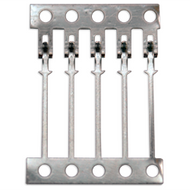

At the base of the system is the shadow mask support which prevents the thin and flexible shadow masks from warping. The shadow masks (sold separately) are then placed on top of the support. Above the shadow mask, the substrate support holds the substrates in alignment with the mask. The lid is used to bolt everything together into a mechanically stable system that can be mounted in a deposition system at any orientation. Finally, a low strength magnetic sheet is placed on top of the lid to pull the shadow mask in close contact with the substrates.

Update: The Evaporation Stack no longer uses a second substrate holder as the additional lower support.

Video Guide

PLEASE NOTE: The magnetic sheet should now be placed on top of the lid, so that it can be taken off while the substrates are still secure in the stack, thus avoiding damage to the substrates.

This video demonstrates how to load up the low density OFET stack ready to thermally evaporate (vacuum deposit) the source-drain contacts (compatible with most common OFET architectures such as top/bottom gate and top/bottom contacts).

Loading the evaporation stack consists of the below steps:

- Loading the thin flexible mask onto the rigid lower support.

- Loading the substrate support holder on top of the mask

- Loading a substrate into the substrate support

- Adding the magnetic sheet to hold the substrate and mask in close contact

- Screwing the lid on to make a mechanically robust system ready for evaporation

System Overview

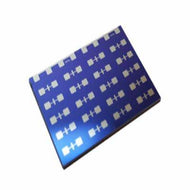

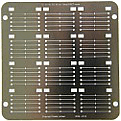

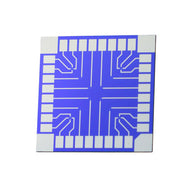

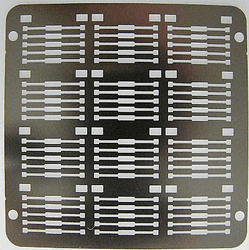

The low density fabrication system has four different masks available (source-drain, gate deposition, active area deposition and insulator deposition) to allow the fabrication of devices in any geometry (top/bottom gates and top/bottom source-drain). The diagrams below show the features on each of the individual masks as well as how they fit together on a substrate.

Note that silicon oxide substrates do not need a gate mask which simplifies fabrication, however the use of a gate mask with quartz-glass substrates can allow lower operating voltages and lower parasitic capacitance.