Tungsten Disulfide

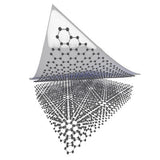

Tungsten disulfide (WS2) in bulk has been used for many years as a dry lubricant due to how it exhibits similar properties to Molybdenum Disulfide (MoS2), such as a low coefficient of friction, high chemical stability, and thermal stability. In 1992, it was discovered that the structure of WS2 made it capable of forming nanotube structures. These nanotubes were the first examples of WS2 being used as a low-dimensional material.

After the discovery of simple mechanical exfoliation techniques to isolate single layers of 2-D materials, it was possible to study the properties of WS2 flakes. It was shown that, just like MoS2, the band-gap of WS2 change from an indirect band-gap of 1.4eV to a direct band-gap of 2eV when changing from a bulk material to a 2-D material. Due to its band-gap, WS2 is seen as a significantly interesting material for many areas of application.

Just like MoS2, WS2 possesses a high on/off ratio in field-effect transistors, controllable spin and valley polarisation, strong geometrical confinement of excitons, and tunable photoluminescence. Additionally, WS2 could lead to increased interest in areas such as photodetectors and multi-junction photovoltaics.

Browse Tungsten Disulfide

Related categories: low dimensional materials, 2D materials

Filter by form: