CuPc, Copper(II) phthalocyanine

CAS Number 147-14-8

Electron / Hole Transport Layer Materials, High Purity Sublimed Materials, Semiconducting Molecules

CuPc, active or HIL layer material for LEDs and organic solar cells

Low price and high purity sublimed grade (>99%) ideal for organic electronics.

Copper(II) phthalocyanine, CAS number 147-14-8, known as CuPc or pigment blue 15 , has been used as an electron donor with fullerene-C60 or phenyl-C61-butyric acid methyl ester (PCBM) in vacuum-deposited organic photovoltaics (OPV)[1]. Power conversion efficiency of about 1% has been achieved [2] and improved efficiency of 4% with pentacene-doped CuPc layer [3]. CuPc has also been used as a hole-injection material for light-emitting diodes. It has been reported that a thin CuPc layer may effectively enhance the hole injection from the anode to the emissive-polymer layer, resulting in a dramatic decrease of operating voltage of the device [4]. Device stability was achieved by depositing a copper phthalocyanine CuPc hole-injection layer HIL on the ITO anode.

The improved stability of the device could be contributed to the good match of its highest-occupied molecular orbital (HOMO) level to the work function of ITO, and the improved wetting property of organic materials on ITO. Moreover, CuPc has very weak absorption of light, with wavelengths from 400 to 500 nm, making it suitable for use in blue and green OLEDs. Effective electron-blocking was also observed for inorganic–organic hybrid perovskite solar cells when CuPc-doped Spiro-OMeTAD was used as the hole-transporting layer [5].

General Information

| CAS number | 147-14-8 |

|---|---|

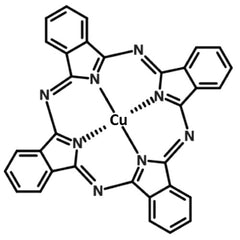

| Chemical formula | C32H16CuN8 |

| Molecular weight | 576.07 g/mol |

| Absorption* | λmax 678 nm (DMF) |

| Fluorescence | λem 459 nm (DMF) |

| HOMO/LUMO | HOMO ~ 5.2 eV, LUMO ~ 3.5 eV |

| Synonyms |

CuPc Copper(II) phthalocyanine Phthalocyanine blue Pigment Blue 15 |

| Classification / Family | Organometallic, Copper complex, Phthalocyanine, Small molecule, Light-emitting diodes, Hole injection layer (HIL) materials, Polymer solar cells, Perovskite solar cells, Sublimed materials. |

*Measurable with the Ossila Optical Spectrometer, for more information see Spectrometer and Spectroscopy Accessories.

Product Details

| Purity | >99% (sublimed) |

|---|---|

| Melting point | 350 °C |

| Appearance | Blue-purple needles/powder |

Sublimation is a technique used to obtain ultra pure-grade chemicals. For more details about sublimation, please refer to the Sublimed Materials.

Chemical Structure

Device Structure(s)

| Device structure | ITO/CuPc(6.0 nm)/[NPB*(3.8 nm)/CuPc (1.5 nm)]4/NPB (15.0 nm)/Alq3 (60.0 nm)/Mg:Ag/Ag [6] |

|---|---|

| Colour |

|

| Max. Luminance | 15,000 cd/m2 |

| Max. Current Efficiency | 10.8 cd/A |

| Device structure | ITO/CuPc(10 nm)/NPB(50 nm)/AlMq2OH*(80 nm)/ LiF(0.7 nm)/Al(80 nm) [7] |

|---|---|

| Colour |

|

| Turn-on Voltage | 9 V |

| Max. Luminance | 14,070 cd/m2 |

| Device structure | ITO/CuPc (15 nm)/NPB (60 nm)/1% v/v C545T*:Alq3 (37.5 nm)/Alq3 (27.5 nm)/Mg:Alq3 (10 nm)/ WO3 (1 nm)/NPB (60 nm)/1% v/v C545T:Alq3 (37.5 nm)/Alq3 (37.5 nm)/LiF(1 nm)/Al (200 nm) [8] |

|---|---|

| Colour |

|

| EQE@ 20 mA/cm2 | 12.6% |

| Current Efficiency@20 mA/cm2 | 49.2 cd/A |

| Power Efficiency@20 mA/cm2 | 5.5 lm W-1 |

| Device structure | ITO/CuPc (15 nm)/NPB (30 nm)/ TPBi:Btp2Ir(acac)* 8 wt% (20 nm)/TPBi (15 nm)/Alq (15 nm)/LiF (1 nm)/Al (100 nm) [9] |

|---|---|

| Colour |

|

| Max. Luminance | 4,798 cd/m2 |

| EQE@ 4 mA/cm2 | 2.1% |

| Current Efficiency@4 mA/cm2 | 2.43 cd/A |

| Power Efficiency@4 mA/cm2 | 0.89 lm W-1 |

| Device structure | ITO/CuPc (25 nm)/NPB (25 nm)/Alq3 (20nm)/LiF (0.3 nm)/Al (0.6 nm)/C60 (30 nm)/Mg:Ag (100 nm) [10] |

|---|---|

| Colour |

|

| Max. Luminance | 17,170 cd/m2 |

| Max. Current Efficiency | 3.93 cd/A |

| Device structure | ITO/CuPc (25 nm)/NPB (45 nm)/Alq3 (60 nm)/LiF (1 nm)/Al (100 nm) [11] |

|---|---|

| Colour |

|

| Max. Luminance | 23,510 cd/m2 |

| Max. Current Efficiency | 4.8 cd/A |

| Max. Power Efficiency | 4.2 lm W-1 |

| Device structure | ITO/CuPc (18 nm)/TPD (50 nm)/Alq3 (60 nm)/BCP (10 nm)/LiF (1 nm)/Al (100 nm) [12] |

|---|---|

| Colour |

|

| Max. Luminance | 5,993 cd/m2 |

| Max. Current Efficiency | 3.82 cd/A |

| Max. Power Efficiency | 2.61 lm W-1 |

*For chemical structure information, please refer to the cited references.

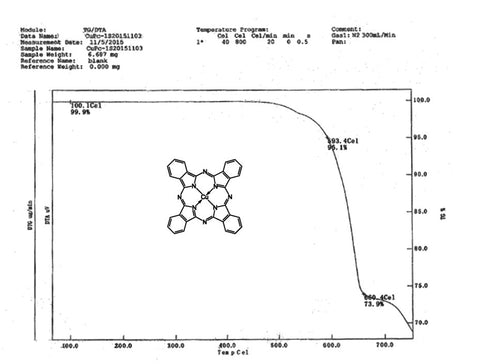

Characterisation

MSDS Documentation

Literature and Reviews

- Influence of codeposition on the performance of CuPc–C60 heterojunction photovoltaic devices, P. Sullivan et al., Appl. Phys. Lett., 84, 1210 (2004).

- Two‐layer organic photovoltaic cell, C.Tang et al., Appl. Phys. Lett., 48, 183 (1986), http://dx.doi.org/10.1063/1.96937.

- Improving efficiency of organic photovoltaic cells with pentacene-doped CuPc layer, W. Chen et al., Appl. Phys. Lett., 91, 191109 (2007), http://dx.doi.org/10.1063/1.2806195.

CuPc MSDS Sheet

CuPc MSDS Sheet