Glove Box and Components

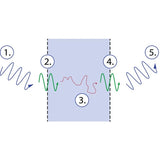

A glove box (or glovebox) creates a stable, sealed environment. Samples are transferred into the main chamber through an antechamber, and gloves enable you work within the glove box.

Our glove box is a complete benchtop system designed with affordability and simplicity in mind. Ideal for many inert atmosphere applications, from air sensitive experiments to handling hazardous materials and chemicals. With a comprehensive and versatile suite of integrated features, our glove box is built for every laboratory, including yours.

We also supply a range of replacement components, including gloves and sensors, to make system maintenance straightforward and easy. And if you need support, our glove box resources provide troubleshooting tips, application guidance, and maintenance advice.

Together, we offer everything you need to easily incorporate an effective Ossila glove box system into your laboratory set up.

Glove Boxes and Glove Box Components

Glove Box

Creates an ISO Class II inert atmosphere with an ultra-low leak rate. Affordable to buy and economical to run, with lower costs than larger systems. Equipped with monitoring software, multiple feedthroughs, independent antechamber sensor boards, and multiple purge options. The compact benchtop design is easily integrated into any workspace.

Glove Box Gloves

Pair of replacement gloves for our glove box or other models with an 8-inch port diameter. Constructed from butyl rubber, they are suitable for use in an inert atmosphere environment and with a range of chemicals. Designed to enable good manual dexterity at only 0.38mm thick.

Oxygen Sensor

Accurate and easy-to-fit replacement 4-pin oxygen sensor for our glove box. With a range of 0.5% to 25% and a resolution of 0.01%, these photoluminescent sensors reliably monitor the internal conditions of your glove box.

Glove Box Nitrile O-Rings

Replacement or spare O-rings for the glove port (pack of 4) and antechamber door (pack of 2). Each set is specifically sized to form a complete seal to maintain an inert atmosphere. Durable and easy to clean as part of a regular maintenance schedule.